Tension stabilizing device of winding machine

A technology of stabilizing device and winding machine, which is applied in the direction of transportation and packaging, conveying filamentous materials, and thin material processing, etc. It can solve the problems of reducing the pressure bearing capacity and fatigue strength of winding products, affecting production continuity, and dramatic changes in tension. , to achieve the effects of improved mechanical properties, high reliability, and fast yarn collection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

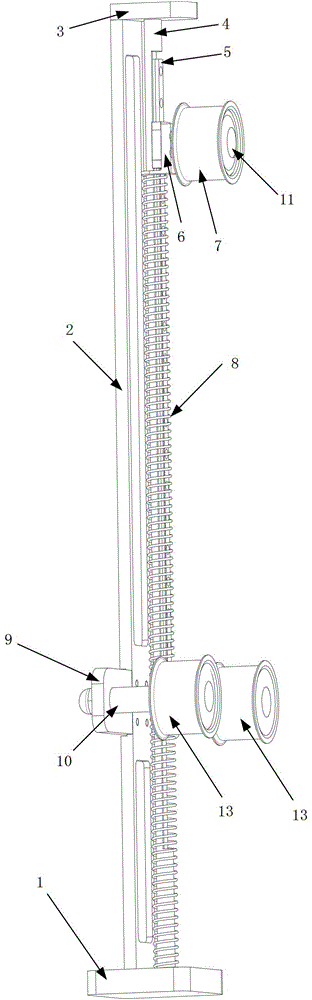

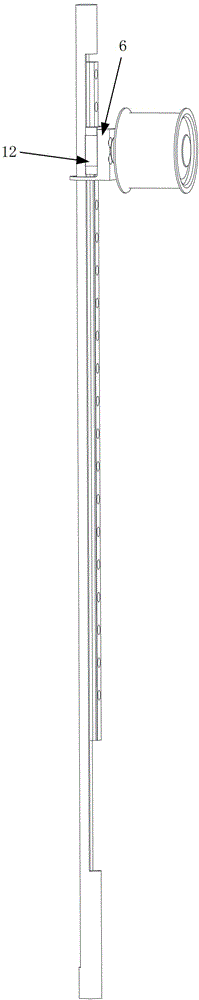

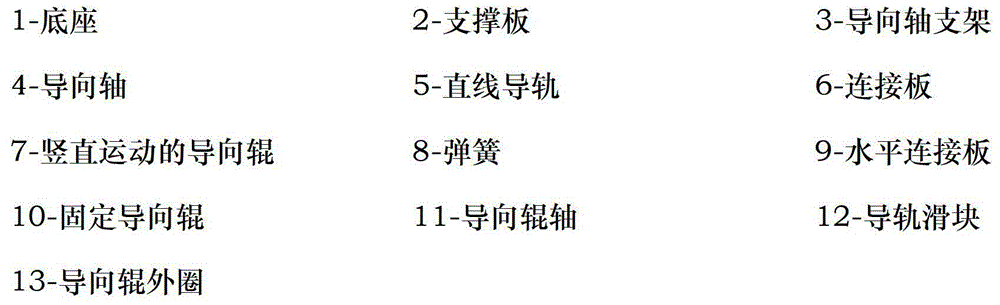

[0015] The present invention is a winding machine tension stabilizing device, such as figure 1 , figure 2 As shown, it includes a base 1, a support plate 2, a guide shaft bracket 3, a guide shaft 4, a linear guide rail 5, a connecting plate 6, a vertically moving guide roller 7, a spring 8, a horizontal connecting plate 9, a fixed guide roller 10 and a guide rail slider 12;

[0016] One end of the base 1 is fixedly connected to the support plate 2, and the other end of the support plate 2 is fixedly connected to the guide shaft bracket 3;

[0017] The two ends of the guide shaft 4 are fixedly connected to the base 1 and the guide shaft support 3 by screws respectively, and the guide shaft 4 is provided with a guide rail mounting platform;

[0018] The linear guide rail 5 is fixed in the guide rail installation platform of the guide shaft 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com