Device for conveying steel pipe transversely falling step by step

A technology of conveying device and steel pipe, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of complicated conveying equipment, high manufacturing cost, and difficulty in rolling down one by one. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

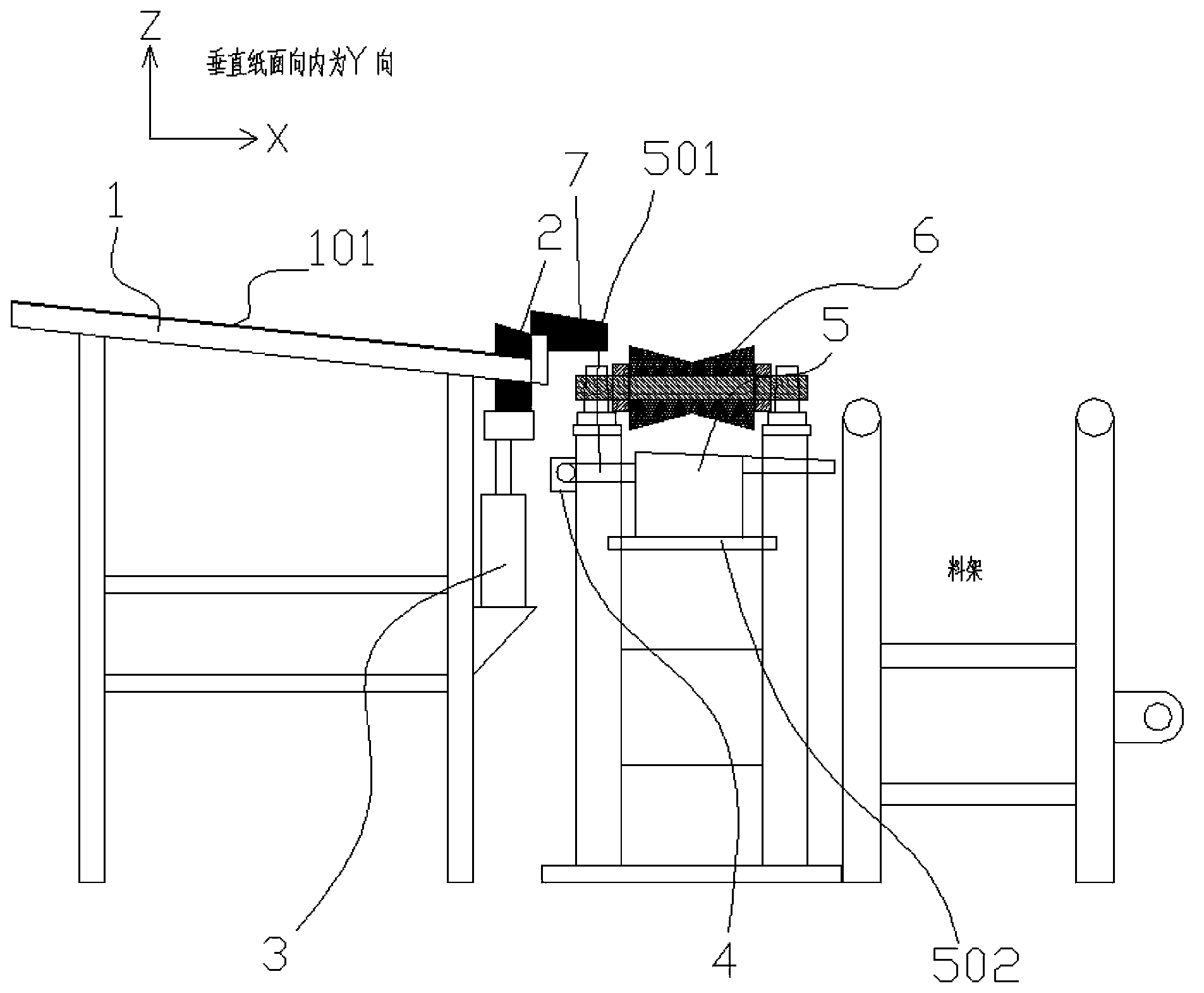

[0024] see figure 1 , assuming that the horizontal movement direction of the steel pipe is the X direction, the axial direction of the steel pipe is the Y direction, and the vertical upward direction is the Z direction; multiple sets of support and guide units are arranged in parallel along the Y direction, figure 1 In addition to the material rack, it and the structure indicate the support and guide unit on the rearmost side along the Y direction, but actually forward along the Y direction, that is, there are multiple sets of support and guide units in the direction perpendicular to the inward direction of the paper surface, which jointly support the steel pipe. undertake.

[0025] The support and guide unit includes: a rolling support rod 1 arranged obliquely downward along the X direction, a vertical cylinder 3 is arranged at the corresponding position at the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com