Stepping self-moving rubber belt conveyor tail used for fast driving

The technology of a step-by-step belt conveyor is applied in the field of the step-by-step self-moving belt conveyor for rapid excavation, and achieves the effects of good market prospects, large equipment length and strong adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

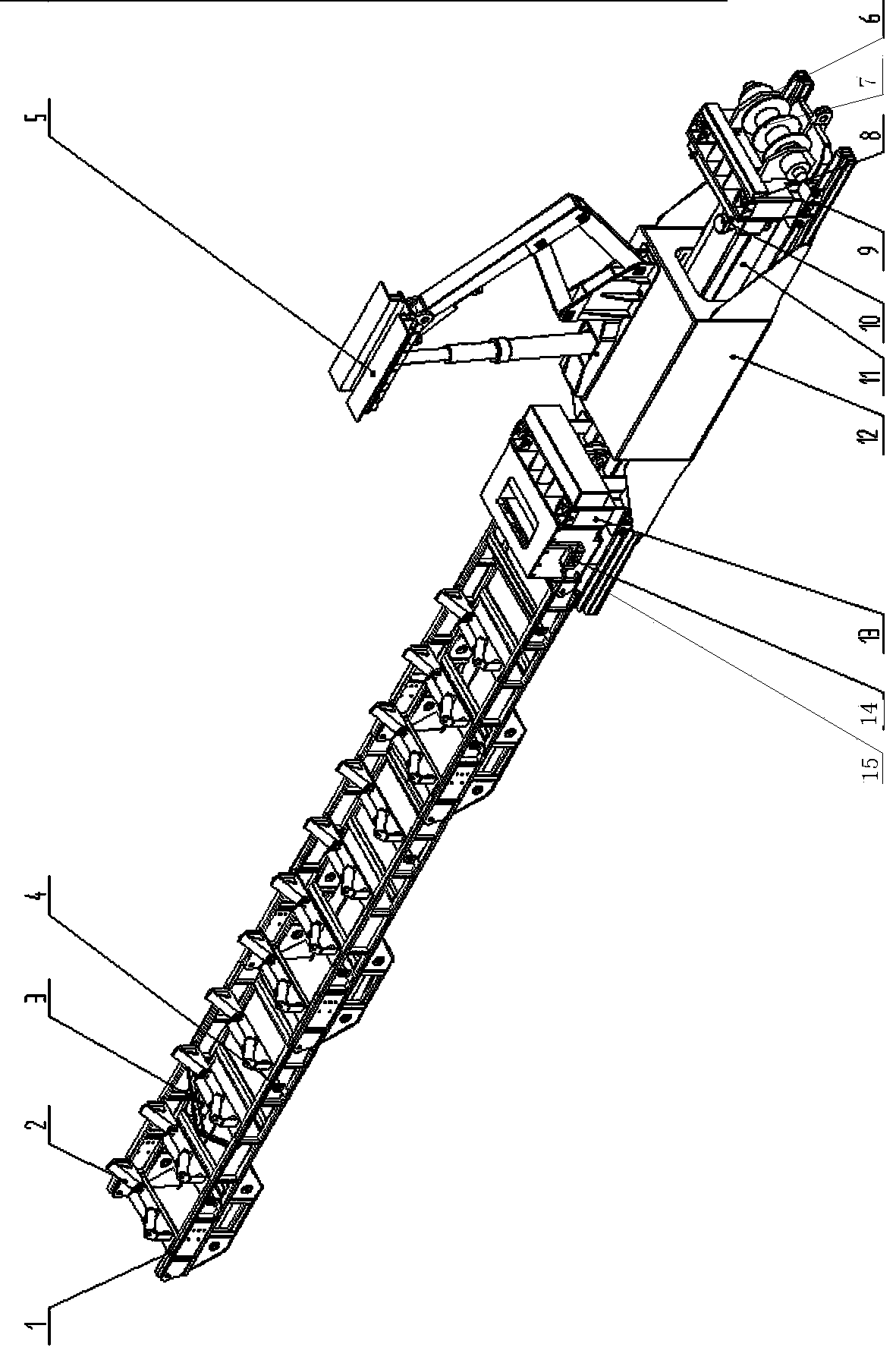

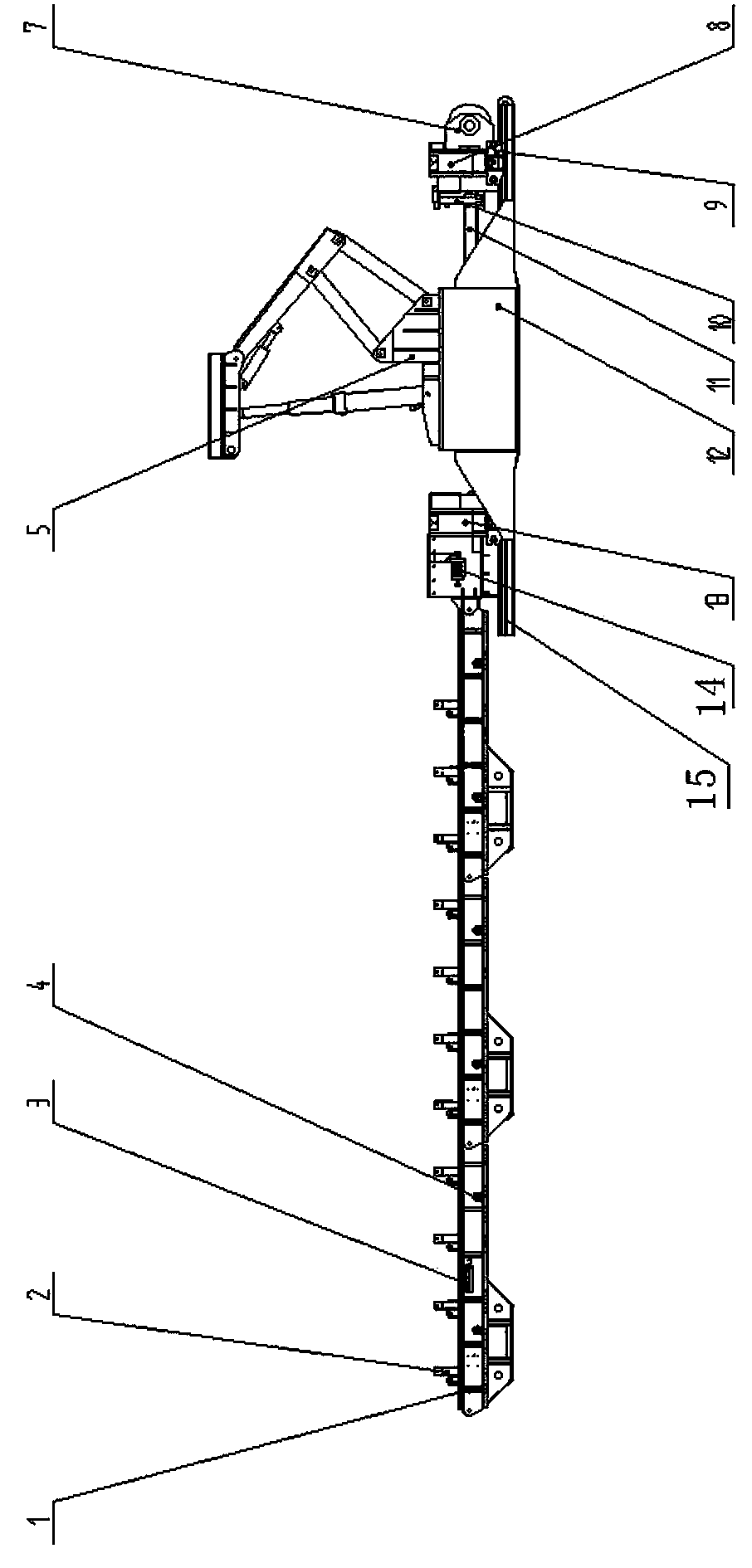

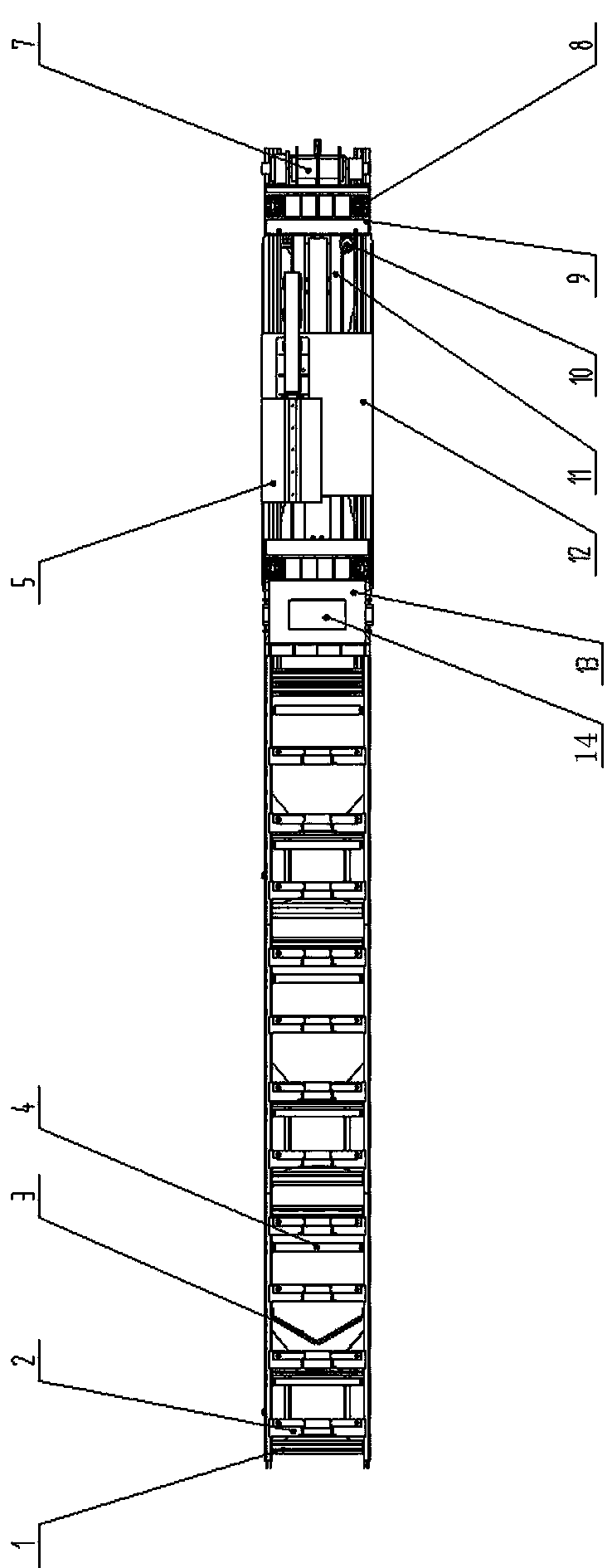

[0033] The specific embodiments of the present invention will be further described with reference to the accompanying drawings.

[0034] The tail of the step-type self-moving belt conveyor for rapid excavation is mainly composed of a self-moving mechanism (frame, bracket) and a rigid frame connected by several sections with pins. The unloading device matched with it during operation can be within the range of its total length of 60m The unloading on the rigid frame realizes the continuous transportation of coal. The tail of the step-by-step self-moving belt conveyor for rapid excavation has a self-moving function, which can be followed by a hydraulic support and a self-moving mechanism when the roadway excavation equipment is moved forward, which is convenient and flexible. The invention of the tail of the step-by-step self-moving belt conveyor reduces the number of reciprocating movements of the traction equipment in the roadway, reduces the damage to the floor by the equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com