Gold and silver red miniature laser fluorescent anti-counterfeiting pull wire and its manufacturing method

An anti-counterfeit pull wire and red micro technology, applied in the direction of flexible coverings, packaging, wrapping paper, etc., can solve the problems of no high-tech content and anti-counterfeiting performance, and achieve the effect of strong anti-counterfeiting performance, complex structure and technology, and high technological content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

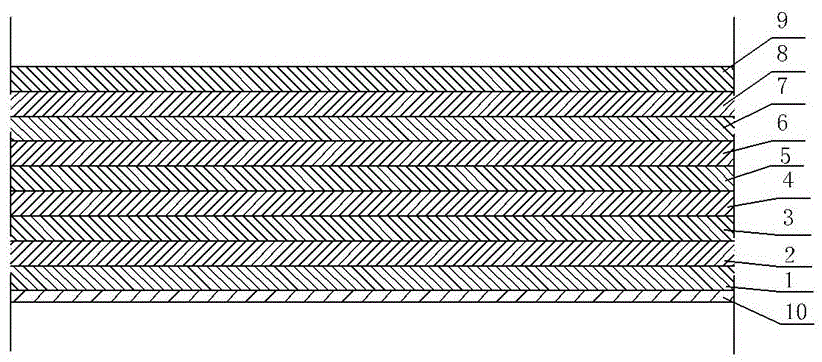

[0021] Such as figure 1 As shown, the present invention is a gold-silver red miniature laser fluorescent anti-counterfeiting pull wire, and its structure includes a polyethylene film 1, a laser film lamination layer 2, a dielectric layer 3, a fluorescent layer 4, and a red light layer arranged on the front of the polyethylene film 1 in sequence from the inside to the outside. 5. Text protection layer 6, aluminum plating layer 7, yellow text layer 8 and pressure-sensitive glue layer 9; polyethylene film 1 is coated with silicone oil layer 10 on the back.

[0022] Such as figure 1 Shown, the method for making anti-counterfeiting backguy, comprises the steps:

[0023] (a). Plate making: using laser micro-engraving technology for plate making;

[0024] (b). Material selection: use 33μm thick laser-specific BOPP polyethylene film 1 for corona treatment;

[0025] (c). In polyethylene film 1 front Double-headed laser luster is pressed on the upper film to form a double-headed gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com