Slider type hydrostatic guideway series with the same installation dimensions as the linear roller guideway

A technology of roller linear guideway and static pressure guideway, which is applied in the field of standard parts and components, can solve the problems that hinder the promotion and improvement of static pressure technology, cannot form standardization, and affect the level of machine tools, so as to achieve enhanced strength, eliminate hydraulic oil pollution, and guarantee The effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be described in detail below with reference to the accompanying drawings.

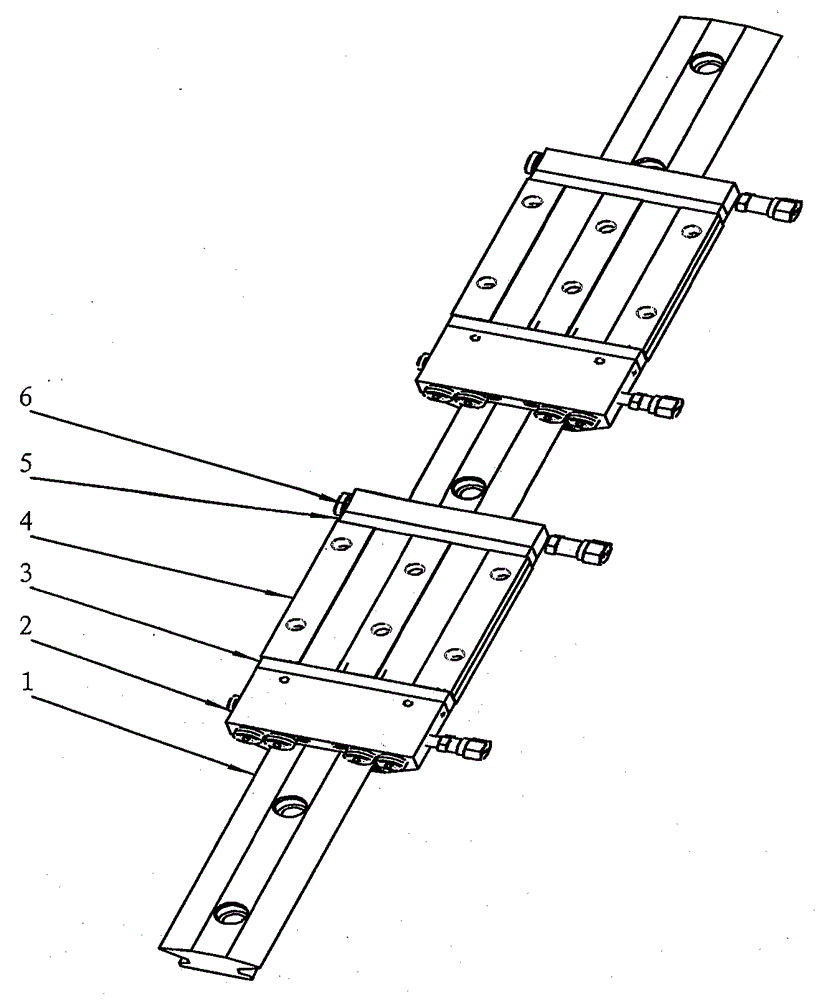

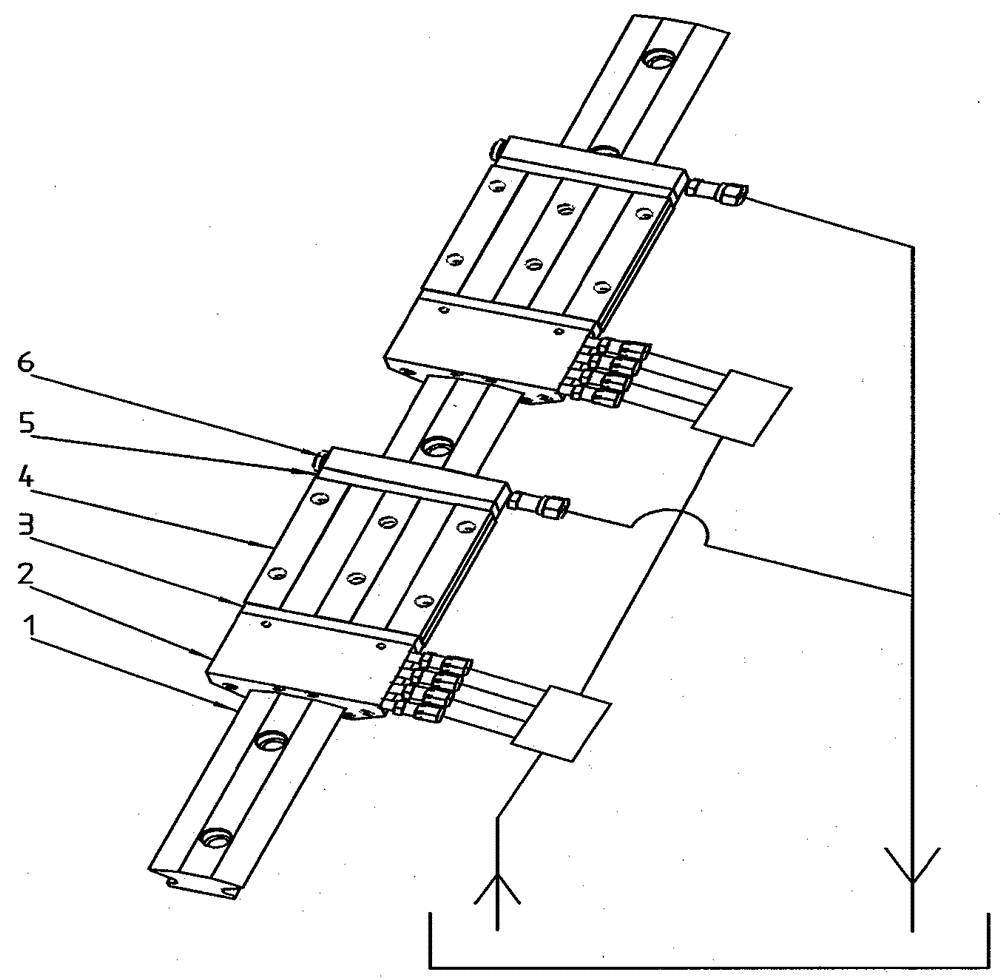

[0019] Such as figure 1 As shown, first install the sealing element on the seal frame 3 and 5, then fasten the oil separating block (or throttle block) 2, the oil drain block 6 and the sealing frame assembly with the slider 4 with screws, and finally The assembly is mounted on the guide rail 1 for testing and application.

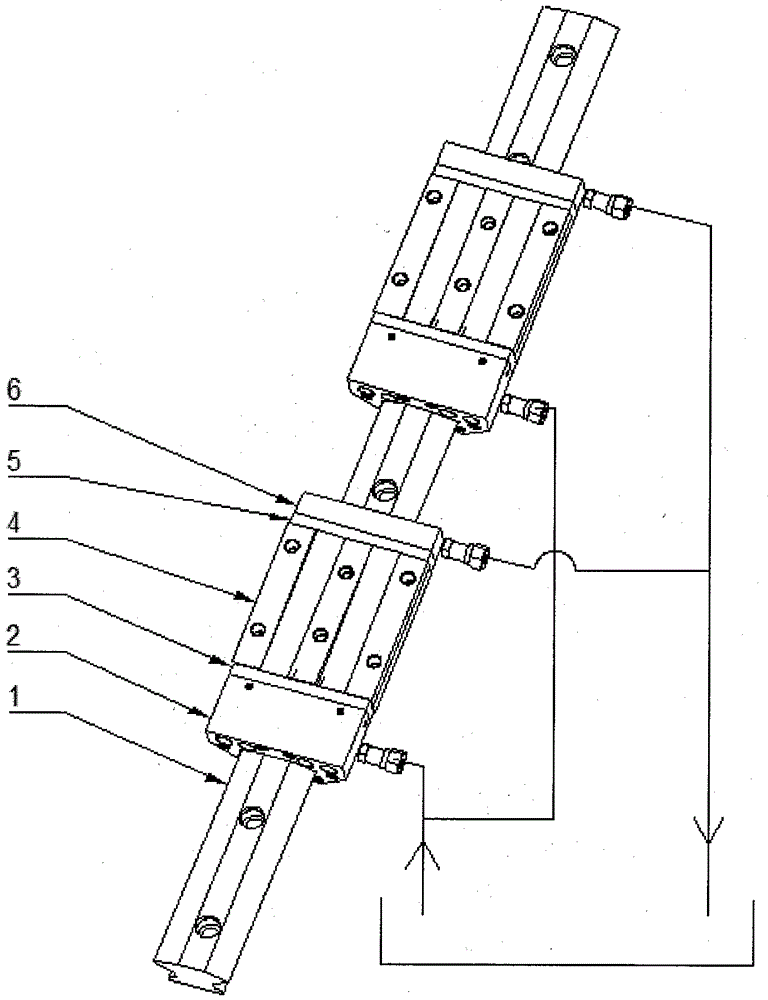

[0020] Such as figure 2 Shown is a constant-pressure static pressure guide. The pressure oil provided by the oil supply system enters the throttle block 2 through the oil inlet pipe. The pressure oil is under the action of the throttle according to the designed throttle ratio (β= inlet pressure / The oil chamber pressure) produces a certain pressure drop and enters the pressure oil chamber of the hydrostatic slider 4, so that a high-pressure oil film is formed between the slider 4 and the bearing surface of the guide rail 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com