Automatic cleaning device for surface of disc type solar condenser

A solar concentrator and automatic cleaning technology, applied in the cleaning method using liquid, cleaning method using tools, cleaning method and utensils, etc., can solve the problem of large temperature difference between morning and evening, affecting the normal operation of the system, and easy freezing of solar panels, etc. problem, to achieve the effect of simple transmission part and ensuring work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

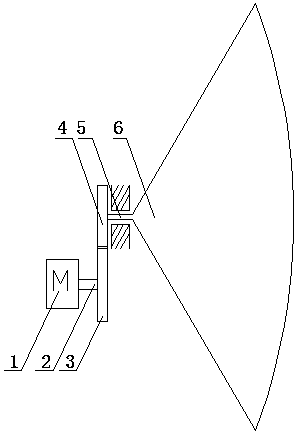

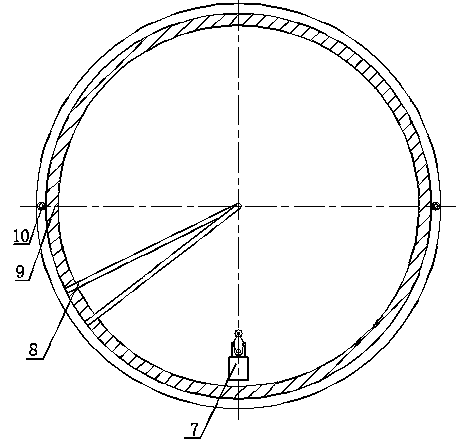

[0012] Such as figure 1 As shown, the present invention The automatic cleaning device on the surface of the dish solar concentrator has a motor 1, an input shaft 2, a first gear 3, a second gear 4 and an output shaft 5, a travel switch 7, a chute 9 and a temperature sensor 10 are all installed on the concentrator. On the optical device 6, the cleaning brush 8 is composed of two cleaning brushes installed at an angle, one end of which is connected to the output shaft 5 of the rotary center, and the other end is connected to the chute 9, and the motor 1 can drive the transmission mechanism to make the cleaning brush 8 move along The chute 9 makes intermittent reciprocating motions on the surface of the concentrator 6 .

[0013] Such as figure 1 , figure 2 as shown, When the cleaning brush 8 touches the travel switch 7 at the bottom of the concentrator 6, the transmission part stops working; the sensor 10 measures the external temperature as a criterion for the start of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com