Method for adjusting the axial play between a motor armature and a bearing, and seat for an armature shaft

A technology of axial clearance and support structure, which is applied in the direction of sliding contact bearings, casings/covers/supports, electromechanical devices, etc., and can solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

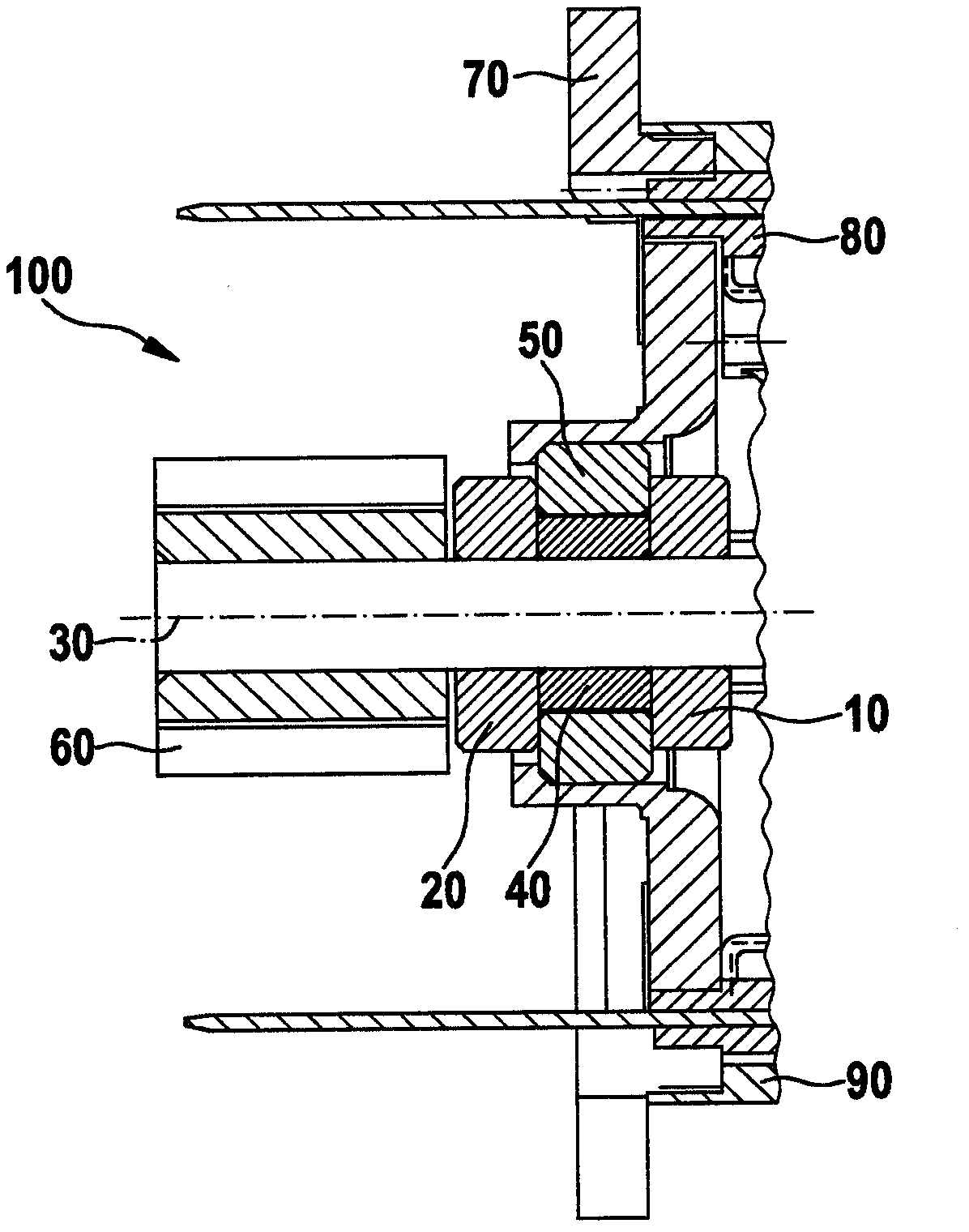

[0031] figure 1 A schematic cross-sectional view of the region of the fixed bearing 50 and the motor armature (not shown) for the throttle valve 100 is shown. The throttle valve is separated from its surroundings by the motor cover 70 and the motor housing 90 or pole head. Furthermore, a commutator 80 and an electric motor (not shown) for operating the throttle valve 100 are arranged inside the throttle valve 100 .

[0032] The armature shaft 30 extends over the entire length of the motor housing 90 and protrudes by a predetermined length from the motor cover 70 , and is accommodated and rotatably mounted in the fixed bearing 50 of the motor cover 70 on the one hand and On the other hand, in a floating bearing (not shown) inside the motor housing 90 . In the region of the free longitudinal end of the armature shaft 30 there is provided a pinion 60 which, in the installed state of the throttle valve 100 , enlarges or reduces the flow passage with a valve (not shown) in the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com