bracket with nut

A nut and bracket technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of fixing, unable to fit into the parts that cannot be fastened, etc., and achieve the effect of ensuring the tightening force and improving the tightening rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

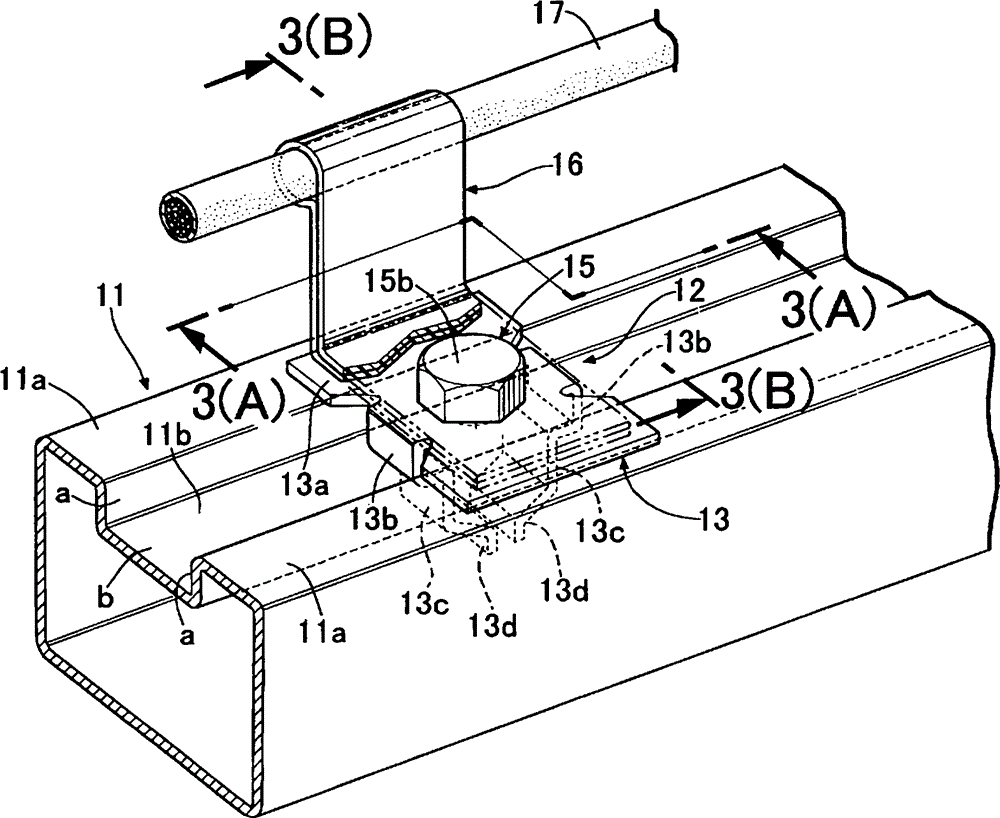

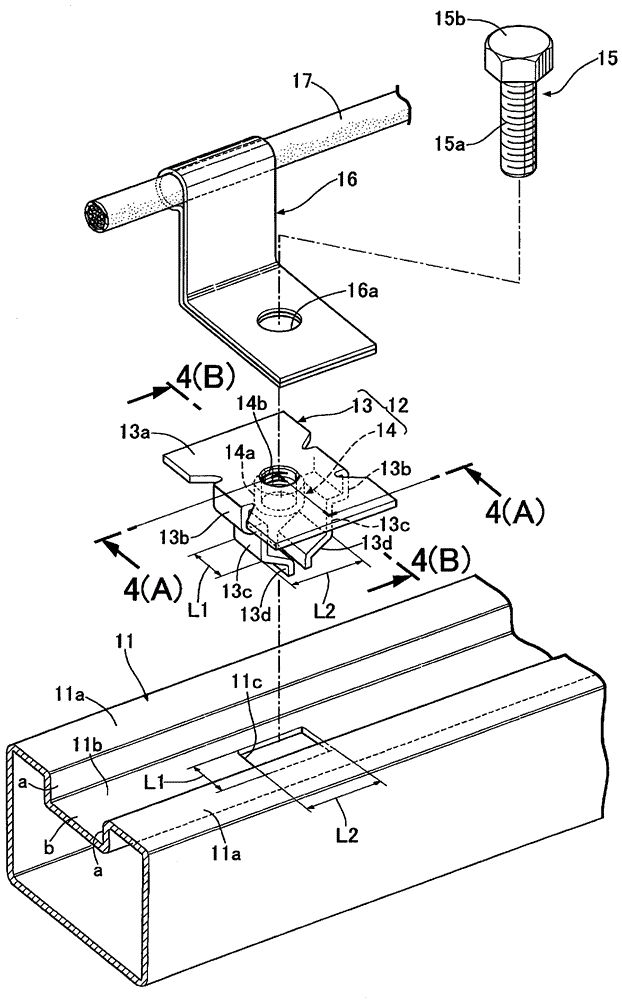

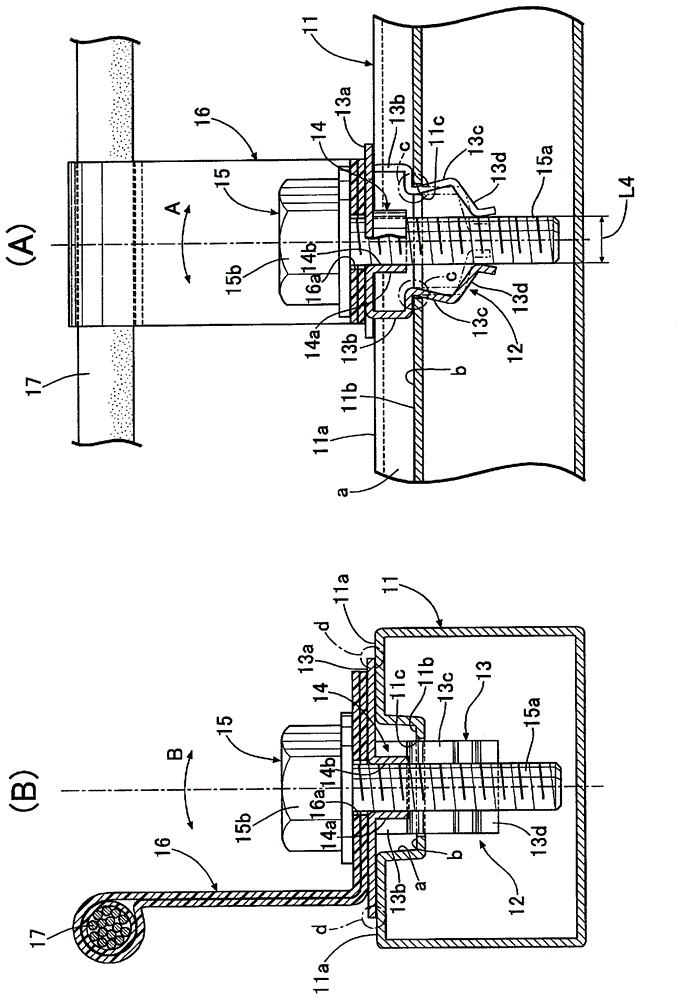

[0048] Such as figure 1 and figure 2 As shown, for example, the body frame 11 of an automobile is a component that constitutes a rectangular closed section, and on one of its four faces, a square groove sandwiched by two surfaces 11a, 11a is formed along the length direction of the body frame 11. Shaped ribs 11b. The rib 11b has a pair of side walls a, a and a bottom wall b sandwiched between the side walls a, a, and a rectangular opening 11c is formed on the bottom wall b.

[0049] Such as Figure 1 ~ Figure 4 As shown, the bracket 12 with a nut installed in the opening 11c of the bottom wall b of the rib 11b of the vehicle body frame 11 is composed of a bracket portion 13 and a nut portion 14 which are integrally formed. The bracket portion 13 is formed by bending a single metal plate, and has a substantially rectangular plate-shaped base portion 13a; The first leg portion 13b, 13b of font-shaped section; A pair of second leg portion 13c, 13c extending linearly downwar...

no. 2 Embodiment approach

[0061] In the second embodiment, the depth of the rib 11 b of the vehicle body frame 11 (the height of the side walls a, a) is increased compared to the first embodiment. Also in such a case, it can cope only by extending the 1st leg part 13b, 13b of the bracket 12 with a nut. If the depth of the rib 11b is increased, the bracket 12 with the nut is likely to fall when a moment in the A direction or a moment in the B direction acts, but it can be prevented by the same function as the first embodiment. The toppling of the bracket 12.

[0062] Next, based on Image 6 A third embodiment of the present invention will be described.

no. 3 Embodiment approach

[0064] In the first and second embodiments, the bracket portion 13 of the nut-equipped bracket 12 is formed of a metal plate, but in the third embodiment, the bracket portion 13 is integrally formed of synthetic resin. Furthermore, a metal nut portion 14 is fitted into the base portion 13 a of the bracket portion 13 . According to this third embodiment, the cylindrically swollen portions of the third leg portions 13d, 13d are expanded by the shaft portion 15a of the bolt 15, thereby, similarly to the first and second embodiments, the first leg portion 13b, 13b and the bent parts c, c between the second leg parts 13c, 13c are engaged with the edge of the opening 11c of the bottom wall b of the rib 11b, so that the bracket 12 with nuts is fixed on the body frame 11. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com