Micro LED array device for display and lighting and preparation method

An LED array, miniature technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as inability to adapt to needs, difficulty in reducing the size of light-emitting units, and resolution limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

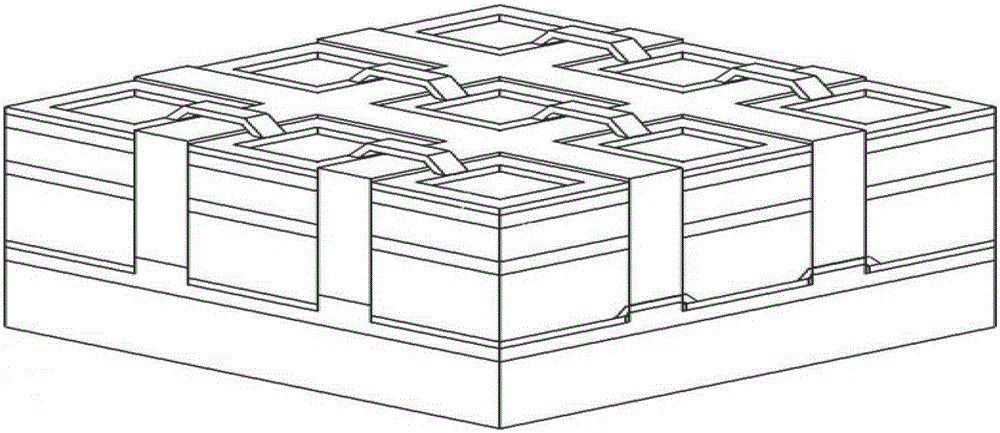

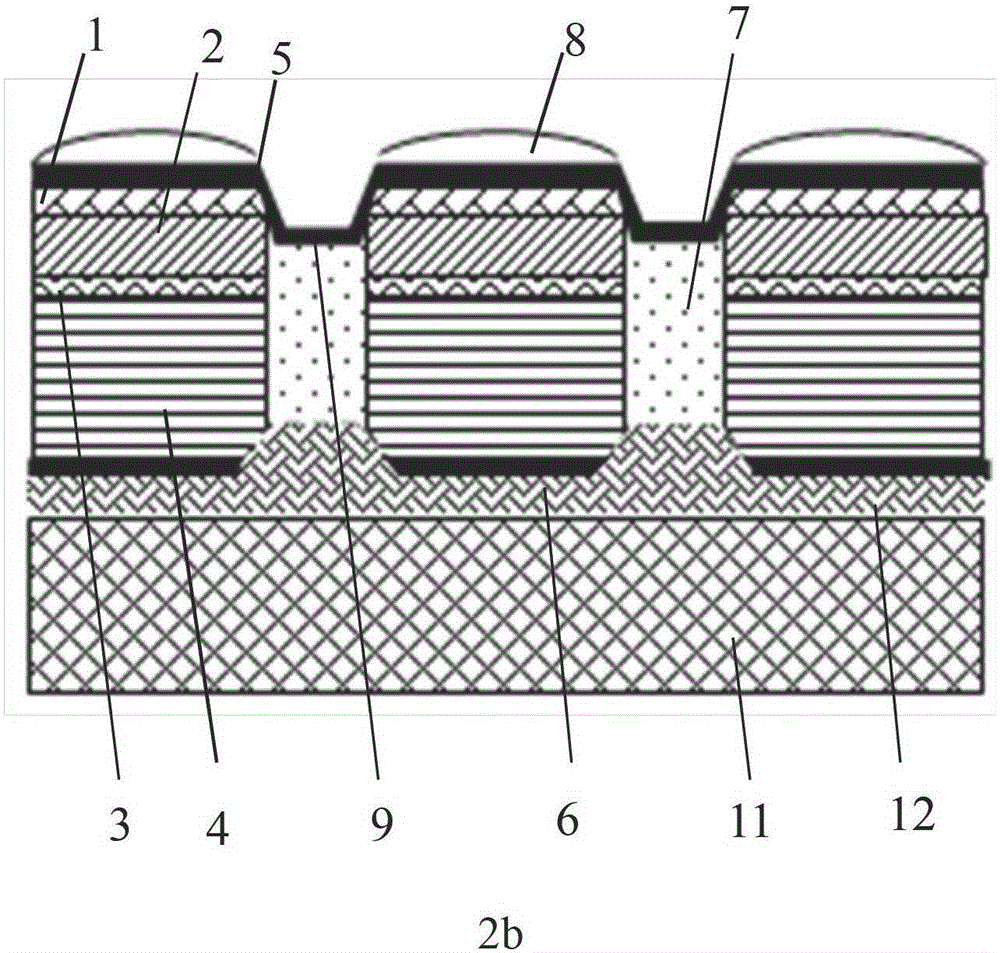

[0027] Specific implementation mode 1. Combination Figure 1 to Figure 8 Describe this embodiment mode; the micro-LED array device for display and illumination described in this embodiment mode includes: a light-transmitting layer 1, a light-emitting layer 2, a reflective layer 3, a substrate 4, an upper electrode 5, an upper electrode lead 9, Lower electrode 6 , lower electrode leads 10 , diaphragm 7 , microlens 8 , adhesive material 12 and substrate 11 .

[0028] The light-transmitting layer 1, the light-emitting layer 2, the reflective layer 3, the substrate 4 and the micro-lens 8 form a square or rectangular or circular or other shaped LED light-emitting unit. The upper surface of the reflective layer 3 is the luminous layer 2 , the light-transmissive layer 1 and the microlens 8 in sequence, and the lower surface of the reflective layer 3 is the substrate 4 . The LED light-emitting units are uniformly arranged to form a light-emitting unit array. Between the light-emitti...

specific Embodiment approach 2

[0031] Specific embodiment two, combine Figure 9 Describe this embodiment mode, this embodiment mode is the manufacturing method of the micro-LED array device used for display and lighting described in the first specific embodiment mode, this embodiment mode adopts a top-down manufacturing method, that is, the front structure is fabricated first, and then , then protect the front structure and prepare the back structure; the specific process is:

[0032] A. Cleaning and front protection of light-emitting chips:

[0033]a) The substrate material used in this embodiment is a light-emitting chip, and the light-emitting chip used is composed of a light-transmitting layer, a light-emitting layer, a reflective layer and a substrate, such as Figure 9 as shown in a.

[0034] b) Cleaning the light-emitting chip. Then prepare a layer of protective film on the upper surface of the light-emitting chip, that is, the upper surface of the light-transmitting layer, such as Figure 9 as ...

specific Embodiment approach 3

[0060] Specific Embodiment 3. This embodiment is an example of the method for preparing a micro-LED array device for display and lighting described in Specific Embodiment 2:

[0061] 1. Cleaning and front protection of light-emitting chips:

[0062] a. The light-emitting chip used in the present invention is an AlGaInP-LED epitaxial wafer, which is composed of a light-transmitting layer, a light-emitting layer, a reflective layer and a substrate, and the thickness of the light-emitting chip is 200 μm to 1000 μm.

[0063] b. The material of the upper protective film is silicon dioxide or silicon nitride or a composite film composed of silicon dioxide and silicon nitride or metal or organic material or inorganic material or other film materials that can play a protective role. The preparation method of the protective film is electron beam evaporation, radio frequency sputtering, magnetron sputtering, sol-gel method or other film growth methods.

[0064] 2. Preparation of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com