Automatic gas sensor calibration system and gas sensor calibration method thereof

A gas sensor and automatic calibration technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of complex equipment and high calibration cost, and achieve the effect of low cost, convenient calibration, and low calibration environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

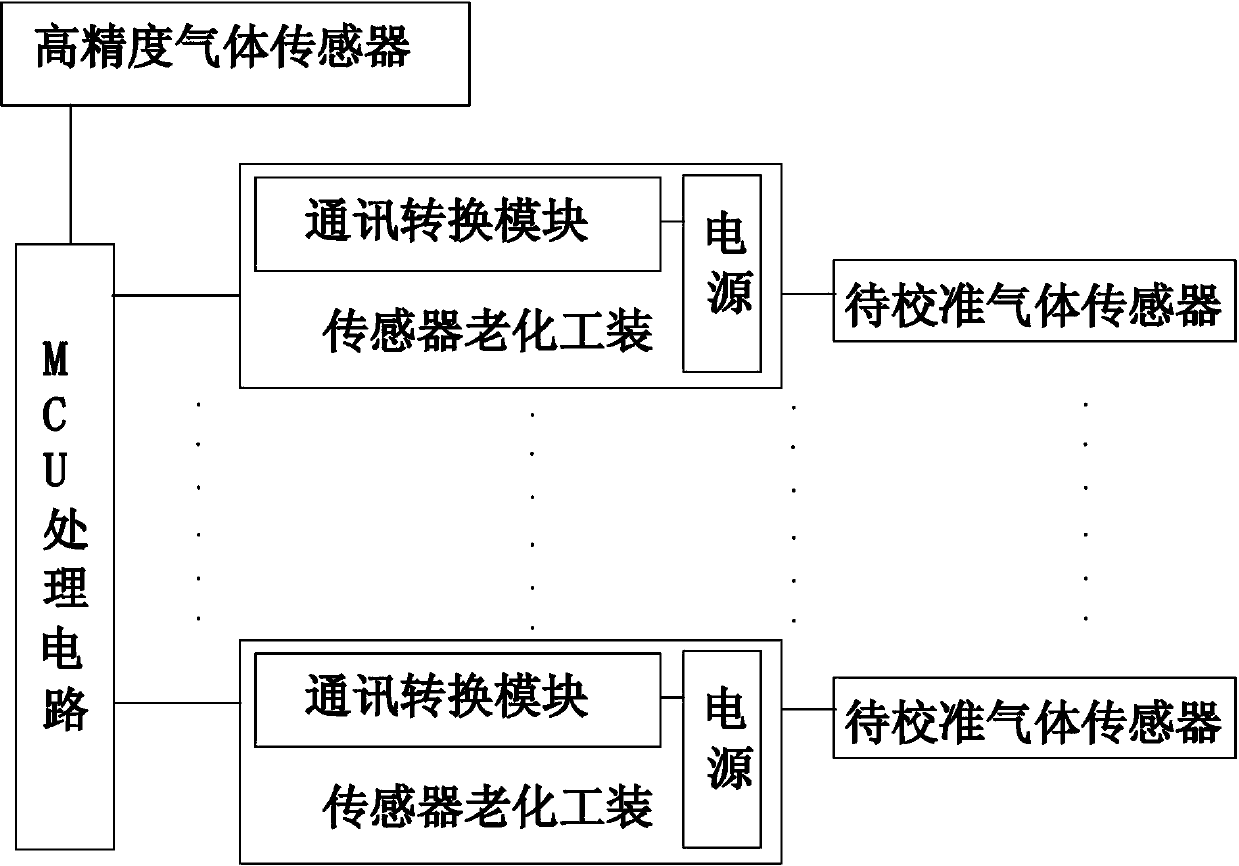

[0021] An embodiment of a gas sensor automatic calibration system, such as figure 1 As shown, it includes multiple sensor aging kits with communication conversion modules. The specific number depends on the test needs, such as 10, 100, etc., so that multiple gas sensors can be calibrated at one time. It also includes a microprocessor with timing function The gas concentration sampling input terminal of the microprocessor circuit is connected to the output terminal of the high-precision gas sensor; the communication conversion module has an input terminal and an output terminal for communicating with the gas sensor to be calibrated, and the microprocessor circuit The calibration signal output end of the detector circuit is connected to the input end of the communication conversion module, and the high-precision gas sensor is CO 2 The gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com