Preparation method of perylene tetracarboxylic acid-graphene heterojunction based photo-anode material

A technology of perylene tetracarboxylic acid and heterojunction is applied in the field of preparation of perylene tetracarboxylic acid-graphene heterojunction-based photoanode materials, which can solve the problem of unfavorable probe molecules, covalent bonding, and difficulty in synthesizing ribbons. On the active group and other issues, to achieve the effect of improving the comprehensive analysis performance and good optical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: The preparation method of the perylene tetracarboxylic acid-graphene heterojunction-based photoanode material: firstly, the perylene tetracarboxylic acid is synthesized, and then compounded with graphene in a certain proportion. The synthesis process of perylene tetracarboxylic acid is as follows: first, add perylene tetracarboxylic dianhydride into 4% potassium hydroxide solution, and stir at 60°C until it is completely dissolved. Add 0.08 mol L dropwise with stirring -1 Hydrochloric acid solution until pH = 4.5 is obtained, wherein as the pH of the solution decreases, the formation of solid perylenetetracarboxylic acid is accompanied. After it was completely precipitated, it was filtered, washed, and vacuum-dried to obtain red perylene tetracarboxylic acid with a yield of 92.5%.

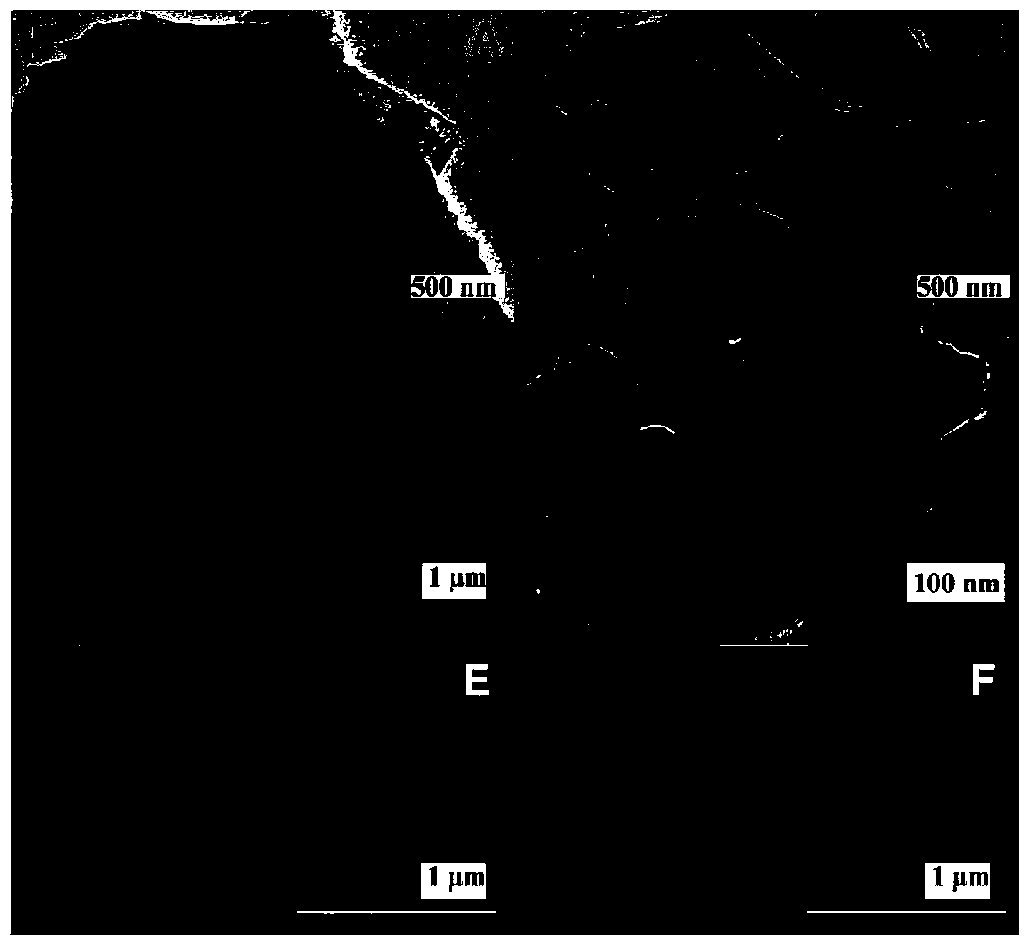

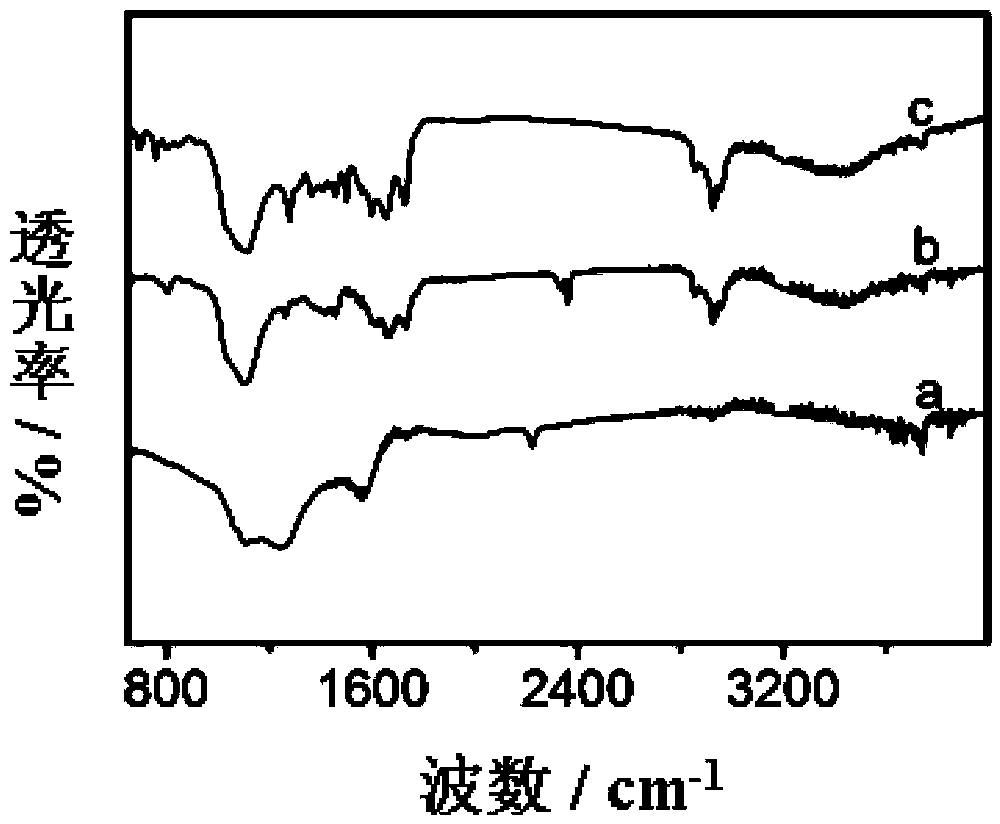

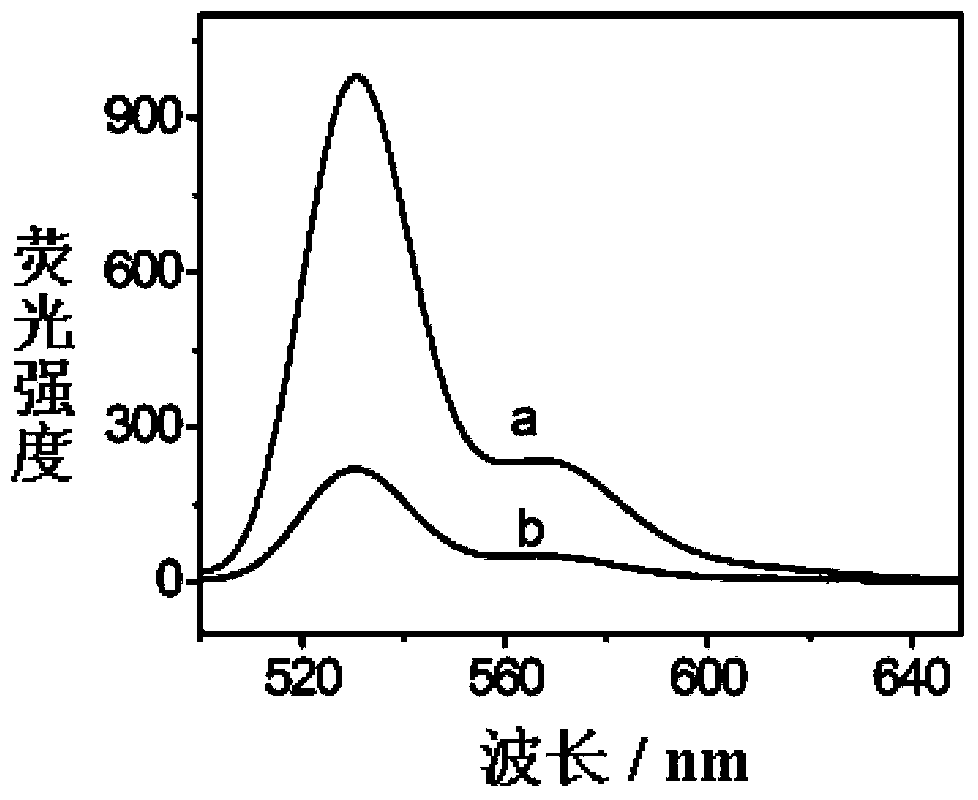

[0017] The specific scheme for preparing perylenetetracarboxylic acid / graphene heterojunction is as follows: First, prepare 0.05×10 -4 mol L -1 DMF solution of perylenetetra...

Embodiment 2

[0020] Example 2: The preparation method of perylene tetracarboxylic acid-graphene heterojunction-based photoanode material: firstly, perylene tetracarboxylic acid is synthesized, and then it is combined with graphene in a certain ratio. The synthesis process of perylene tetracarboxylic acid is as follows: first, add perylene tetracarboxylic dianhydride into 5% potassium hydroxide solution, and stir at 65°C until it is completely dissolved. Add 0.1 mol L dropwise with stirring -1 Hydrochloric acid solution until pH = 4.8 is obtained, wherein as the pH of the solution decreases, the formation of solid perylenetetracarboxylic acid is accompanied. After it was completely precipitated, it was filtered, washed, and vacuum-dried to obtain red perylene tetracarboxylic acid with a yield of 96.5%.

[0021] The specific scheme for preparing perylenetetracarboxylic acid / graphene heterojunction is as follows: First, prepare 1×10 -4 mol L -1 DMF solution of perylenetetracarboxylic ac...

Embodiment 3

[0023] Example 3:The preparation method of perylene tetracarboxylic acid-graphene heterojunction-based photoanode material: firstly, perylene tetracarboxylic acid is synthesized, and then it is combined with graphene in a certain ratio. The synthesis process of perylene tetracarboxylic acid is as follows: first, add perylene tetracarboxylic dianhydride into 6% potassium hydroxide solution, and stir at 70°C until it is completely dissolved. Add 0.12 mol L dropwise with stirring -1 Hydrochloric acid solution until pH = 5.1 is obtained, wherein as the pH of the solution decreases, the formation of solid perylenetetracarboxylic acid is accompanied. After it was completely precipitated, it was filtered, washed, and vacuum-dried to obtain red perylene tetracarboxylic acid with a yield of 97.5%.

[0024] The specific scheme for preparing perylenetetracarboxylic acid / graphene heterojunction is as follows: First, prepare 2×10 -4 mol L -1 DMF solution of perylenetetracarboxylic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com