Ceiling

A technology for suspended ceilings and keels, applied in the direction of ceilings, building components, covering/lining, etc., can solve the problems of noise and odor, high cost, non-standard operation methods, etc., achieve free disassembly and assembly, facilitate production and transportation, and eliminate The effect of construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

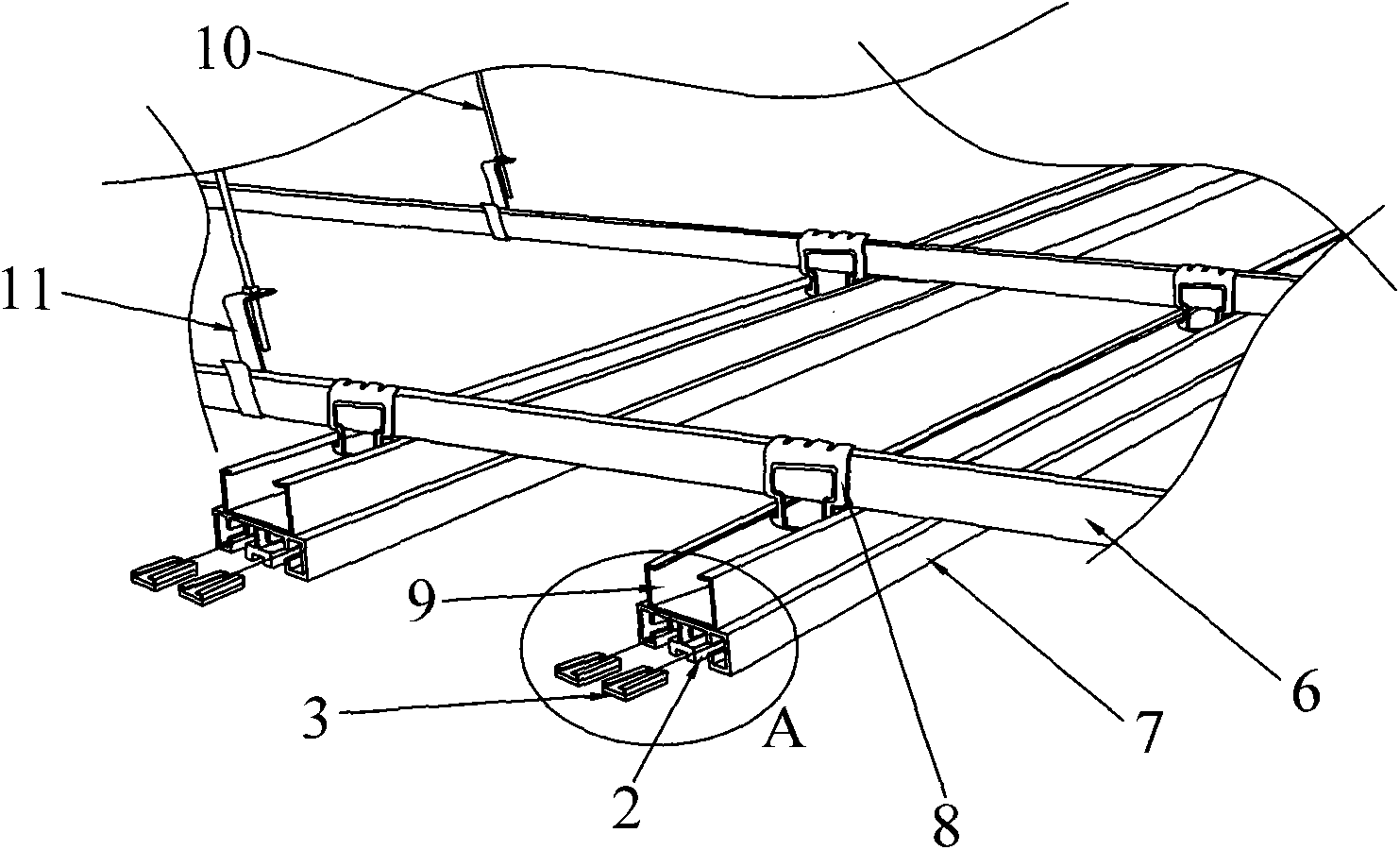

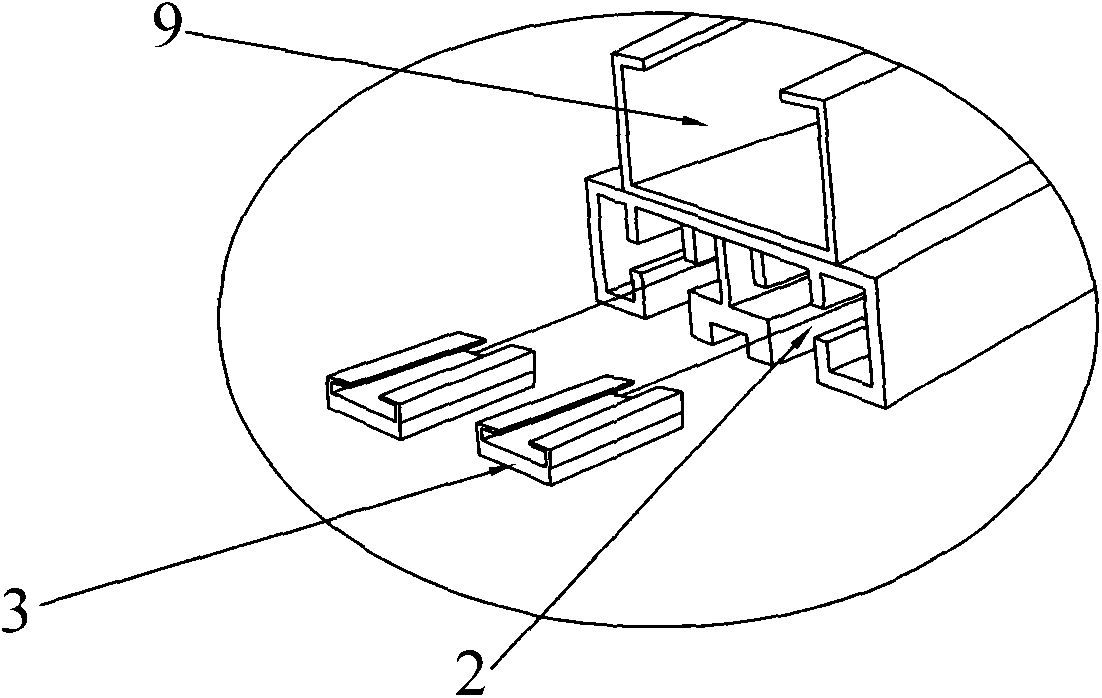

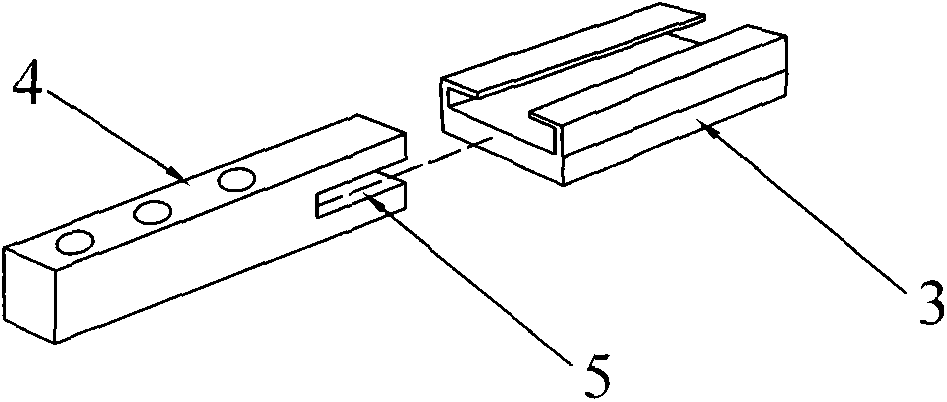

[0022] see figure 1 and Figure 5 As shown, the present invention provides a suspended ceiling, comprising a fixing device for being attached to the top of a wall, a flat keel frame and at least one rectangular ceiling panel 1, the fixing device, the keel frame and the ceiling panel are composed of Put down and connect successively, wherein, the bottom surface of the keel skeleton is concave upward to have a structure with at least two track grooves 2 parallel to each other. The inserting plate inserted in the same track groove is at least two clamping plates 3 arranged at intervals, and each of the suspended ceiling panels is connected with four corners of the top surface to push upwards into the track groove. The clamping block 4, the outer end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com