Fur hang dyeing machine

A hanging dyeing machine and fur technology, which is applied in the field of fur hanging dyeing machines, can solve the problems that there is no equipment for batch processing and dyeing transitional color fur, the fur color is difficult to ensure consistency, and industrial production cannot be formed, so as to save electricity consumption, Simple structure, convenient and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

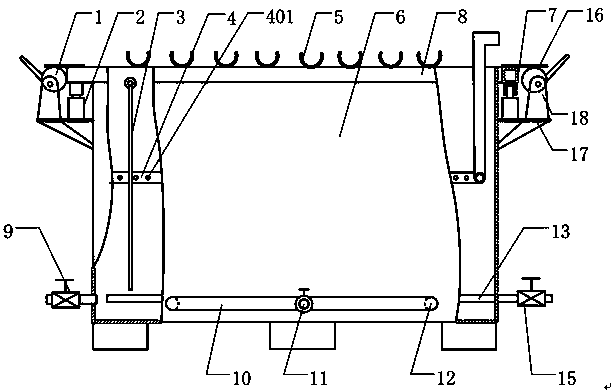

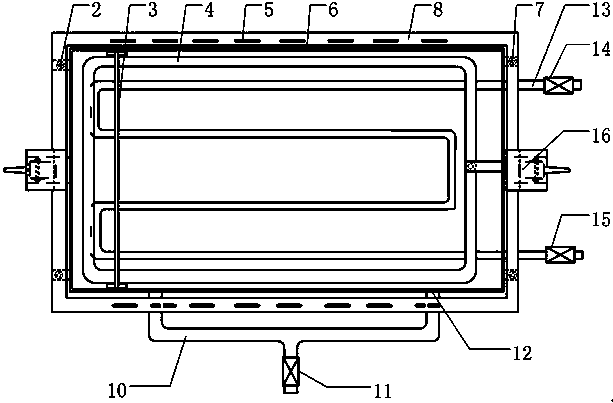

[0017] Such as figure 1 , figure 2 and image 3 Shown: a fur hanging dyeing machine, including a tank body 6, and also includes a frame-type pilot frame 8, a pilot frame lifting adjustment device, a dye solution heating device and a dye solution circulation device; the frame-type pilot frame 8 is installed in the tank in a lifting manner Above the body 1, several pairs of positioning parts 5 are arranged symmetrically on the frame-type pilot frame 8; the pilot frame lifting adjustment device includes a pilot cam 1 and a top plate 16, the top plate 16 is set on the frame-type pilot frame 8, and a support frame is provided outside the tank body 6 17. The support frame 17 is provided with a support plate 18, the pilot cam 1 is installed on the support plate 18 through the cam shaft, the pilot cam 1 is located under the top plate 16, and is connected with the top plate 16 in contact; the dye liquor heating device includes a The steam heating pipe 13 at the bottom, the steam inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com