Energy-saving recovery device and energy-saving recovery method for zinc oxide product

A recovery device, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of low recovery rate of zinc hydroxide, easy deposition at the bottom of the pipeline, no waste heat recovery, etc., to achieve guaranteed recovery rate and high heat recovery rate, accelerate product cooling recovery, and maintain the effect of heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037] The technical solution of the present invention will be described in further detail below in conjunction with specific embodiments.

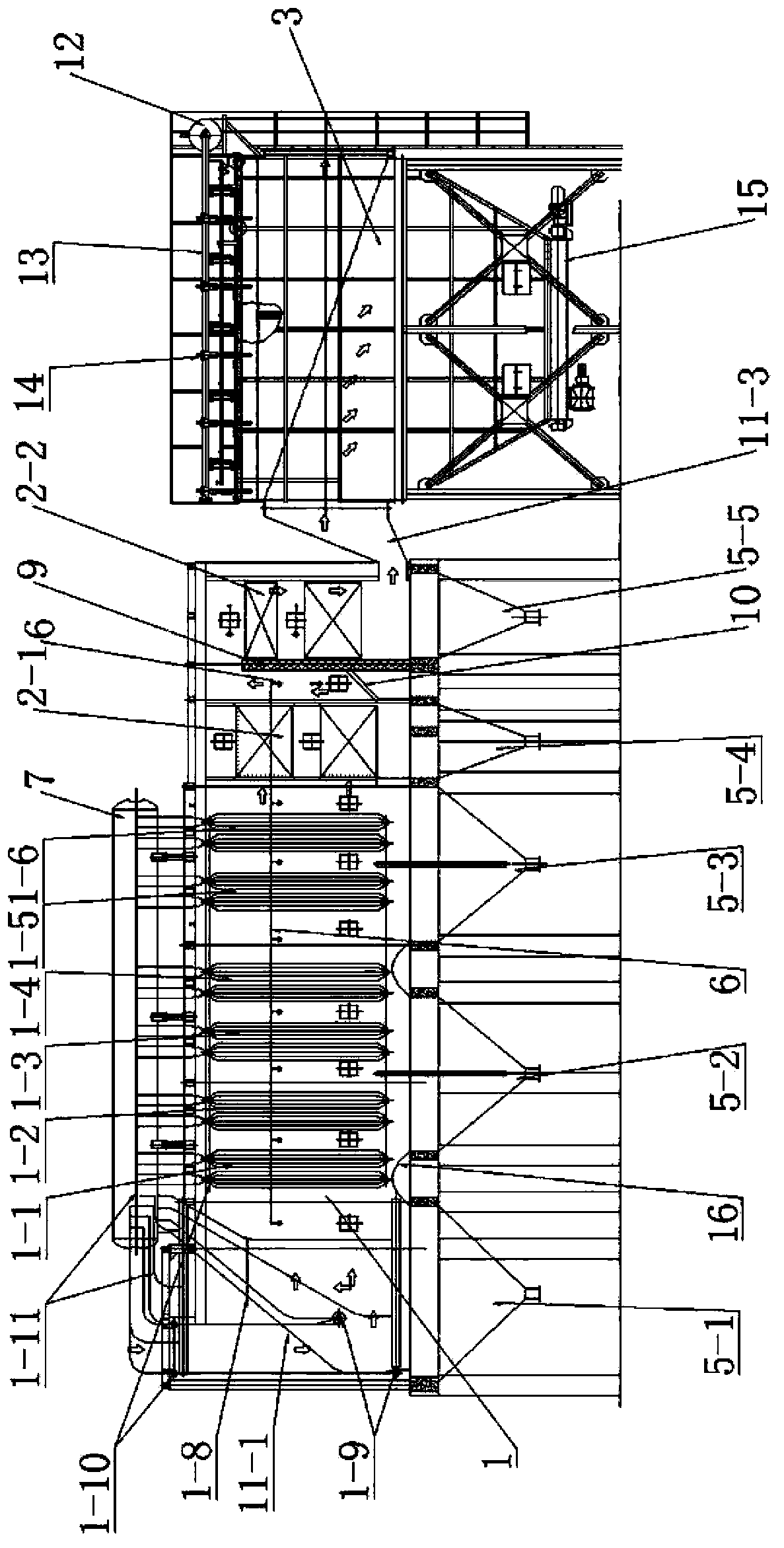

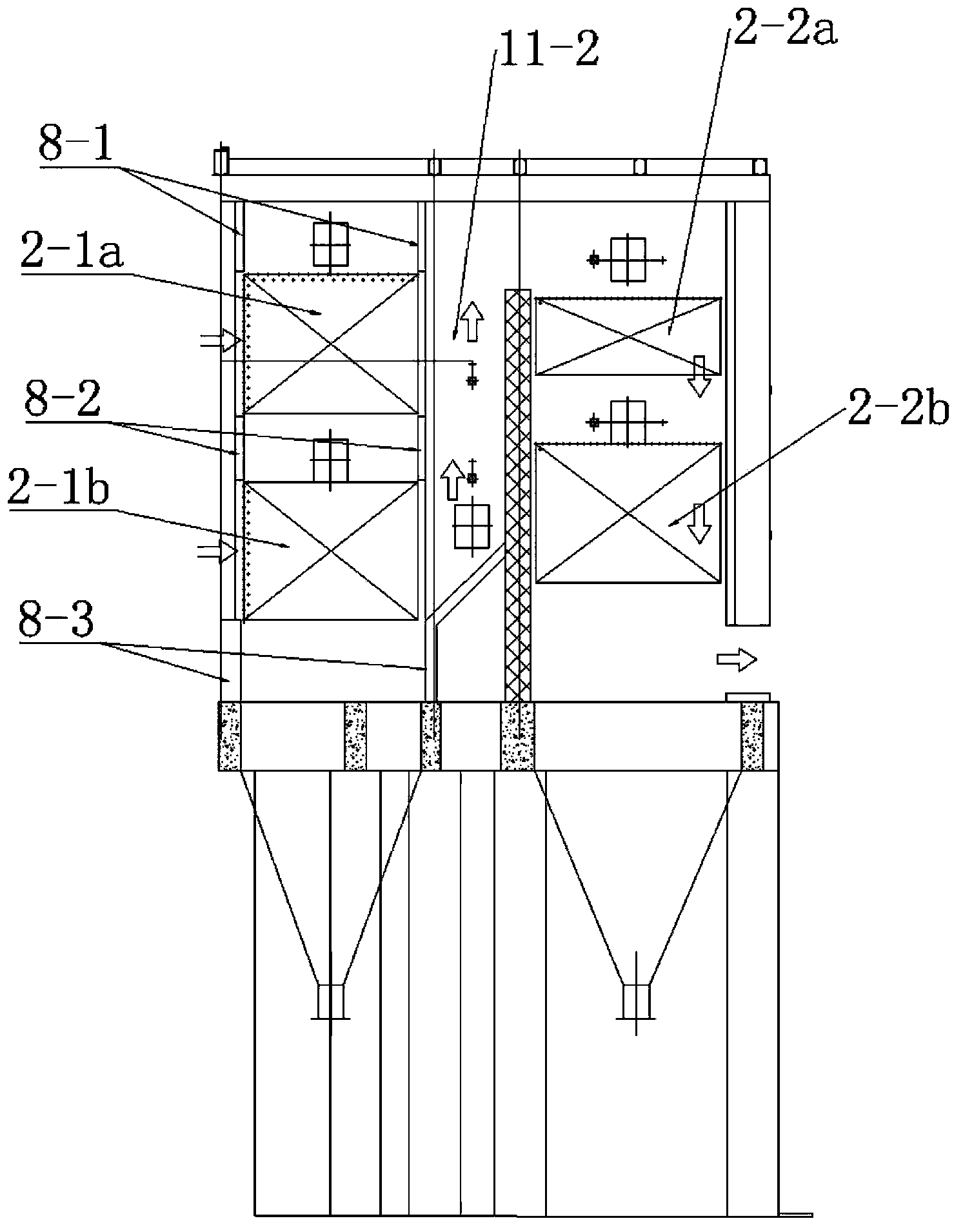

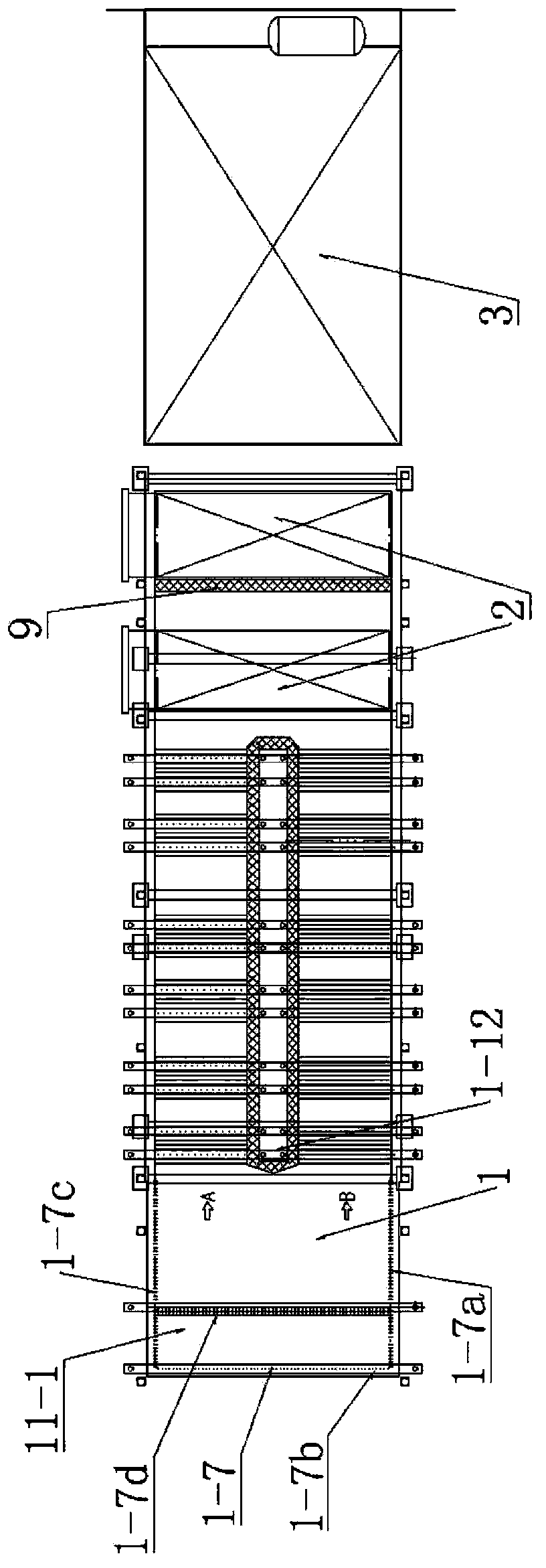

[0038] Such as Figure 1-Figure 3 As shown, the present invention is an energy-saving recovery device for zinc oxide products, which includes a main cold room 1, a secondary cold room 2 and a bag collection room 3 connected in sequence. The main cold room 1 is connected to the zinc oxide production device 4, and the main cold room 1. The bottom of the secondary cold room 2 and the bag collection room 3 are respectively provided with discharge ports, a number of pulsed ultrasonic generators 6 are placed on both sides of the main cold room, and the main cold room 1 is connected with a steam recovery bin 7. The front part of the main cold room is provided with an air inlet passage 11-1, and the air inlet passage is provided with four-sided membrane wall heat exchange tube plates 1-7, the first heat exchange tube plate 1-7a, and the second heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com