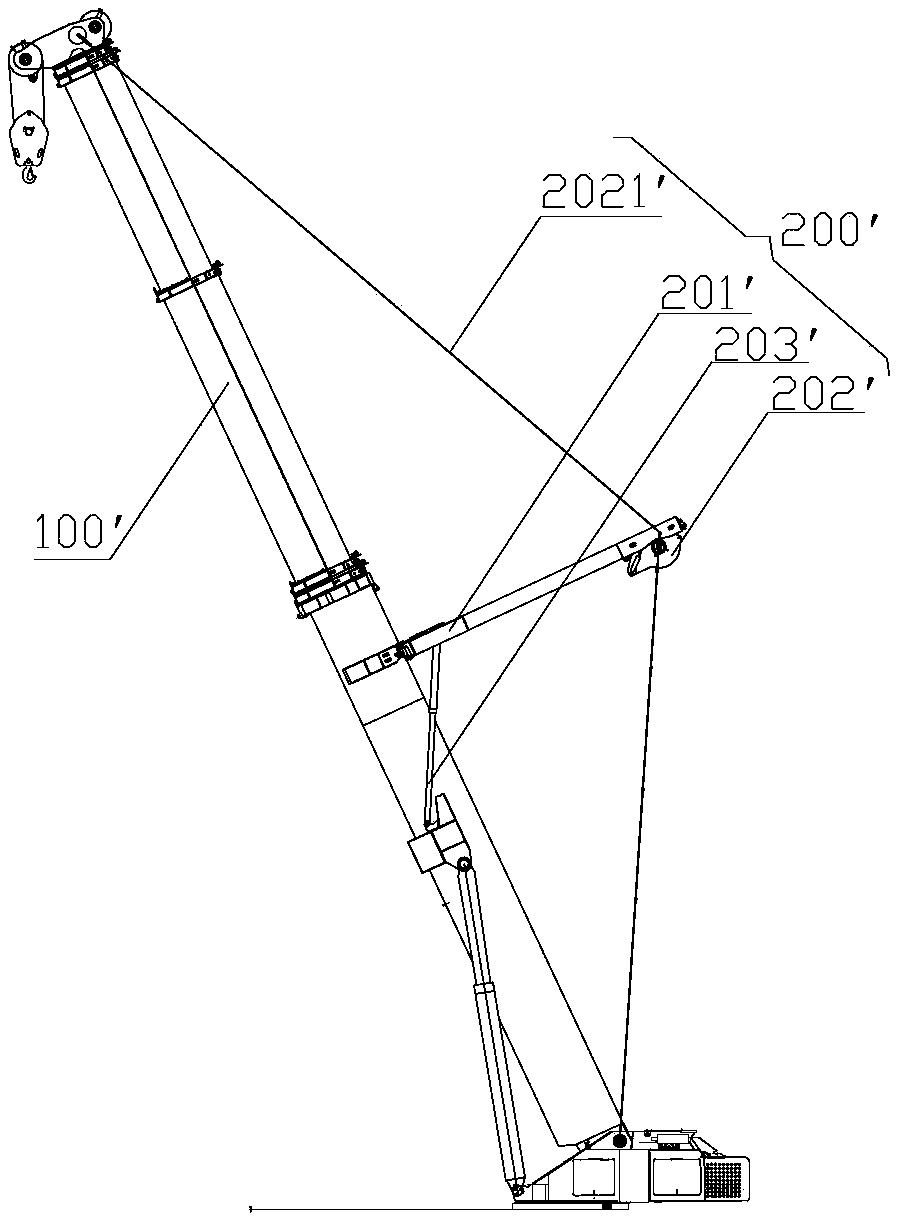

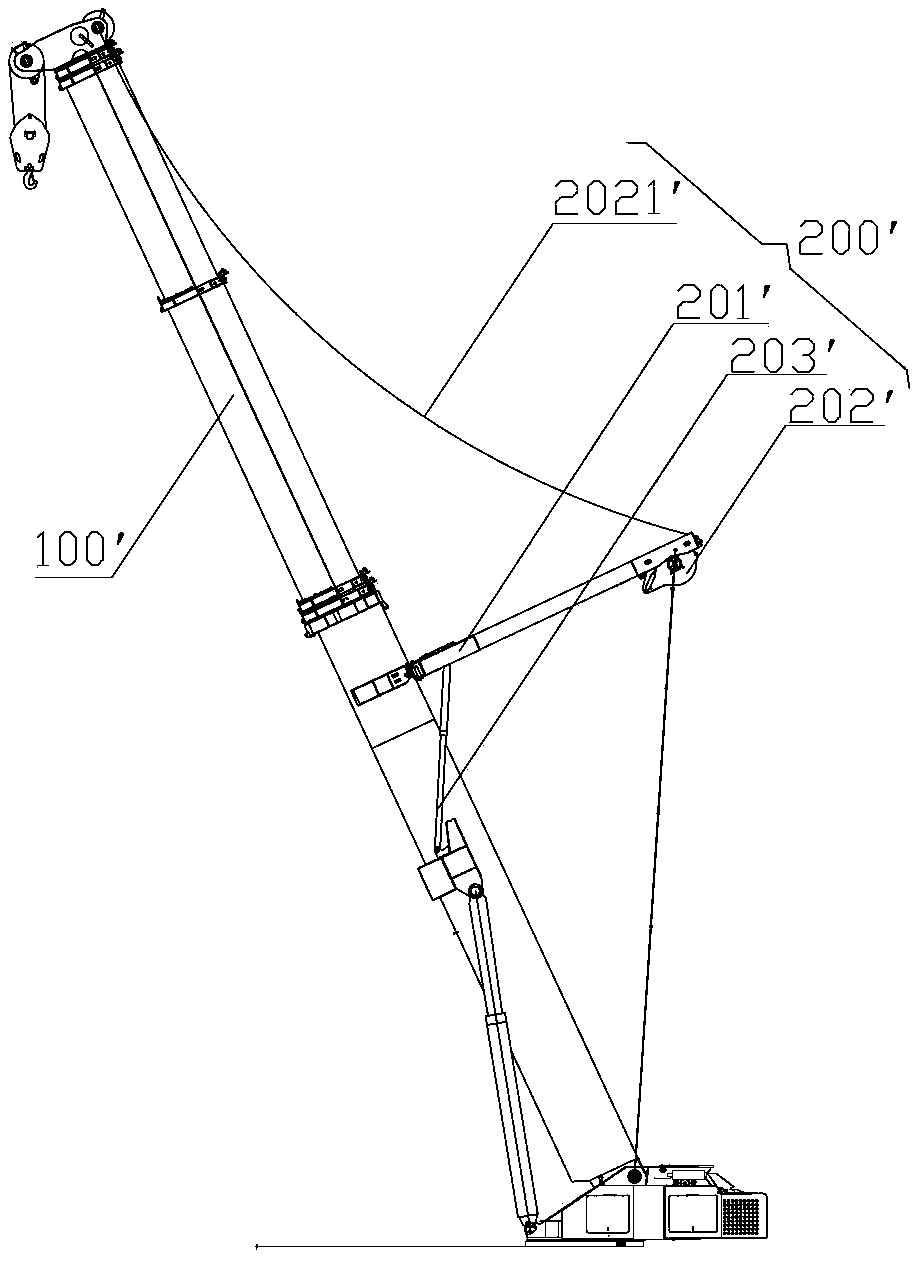

Super-lifting winch control method and system for crane

A control system and control method technology, applied in hoisting devices, transportation and packaging, clockwork mechanisms, etc., can solve problems such as cumbersome operations, potential safety hazards, and real-time matching of the speed of the main arm 100'

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0087] In another specific implementation manner, the above-mentioned control method also includes the steps of:

[0088] S14: Detect the tension on the top of the wire rope 2021 and the retracting state of the winch;

[0089] S141: Determine what state the winch is in, if it is in the state of receiving the rope, execute step S142; if it is in the state of releasing the rope, execute step S143;

[0090] S142: Determine the relationship between the tension of the steel wire rope 2021 and the sum of the gravity of the steel wire rope 2021 and the tension force of the steel wire rope 2021. If it is greater, then perform step S1421; if it is less, then perform step S1422;

[0091] S1421: Decrease the hoisting speed;

[0092] S1422: Increase the hoisting speed.

[0093] S143: Determine the relationship between the tension of the steel wire rope 2021 and the sum of the gravity of the steel wire rope 2021 and the tension force of the steel wire rope 2021. If it is greater, then pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com