Delivery device and delivery method for open-cast mining

A technology for open-pit mining and conveying devices, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of low efficiency and high transportation costs of single-bucket trucks, and achieve improved transportation efficiency, saving transportation costs, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

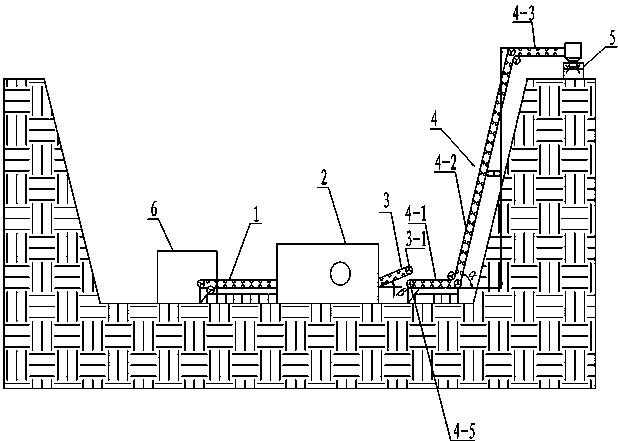

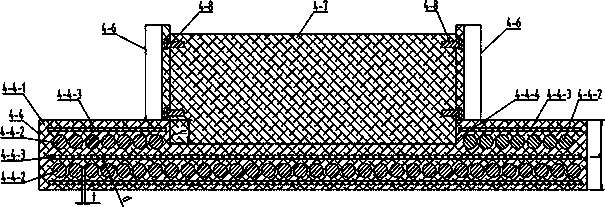

[0023] refer to figure 1 As shown, the conveying device for open-pit mining in this embodiment includes a pit material conveyor 1, a crusher 2, a material output machine 3, a material hoist 4 and a ground material conveyor 5, and each part is sequentially arranged along the material conveying direction. The mine material conveyor 1 is parallel to the mining face of the mine, and is used for horizontal conveying, and its end is connected to the material input port of the crusher 2, and the material output port of the crusher 2 is connected to the material output machine 3. The material hoist 4 comprises a lower horizontal section 4-1, a middle inclined lifting section 4-2 and an upper horizontal section 4-3, and the lower horizontal section 4-1 is connected with the material output machine 3.

[0024] Based on the above technical solution, this embodiment als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com