Middle groove of scraper conveyer, scraper conveyer and fully-mechanized coal mining equipment

A technology of scraper conveyor and baffle groove, which is applied in the field of scraper conveyor and fully mechanized mining equipment, and the middle groove of scraper conveyor, which can solve the problems of affecting the service life of pin rails and damage of pin rails, so as to prolong the service life , reduce impact and improve adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

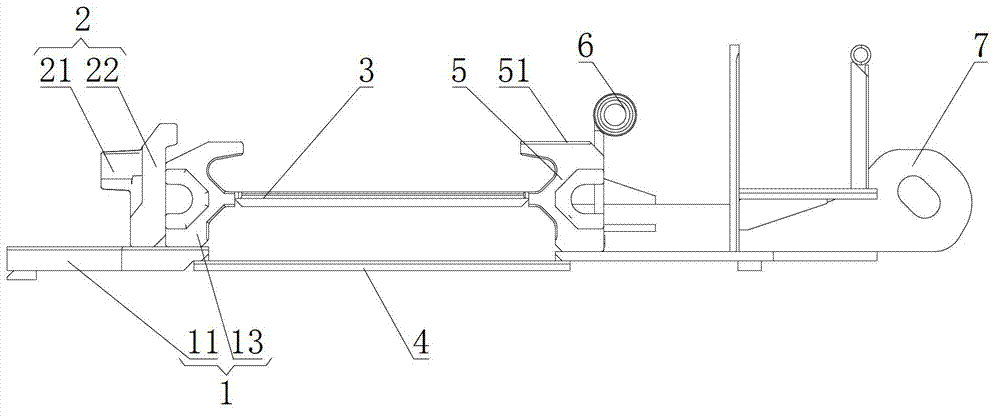

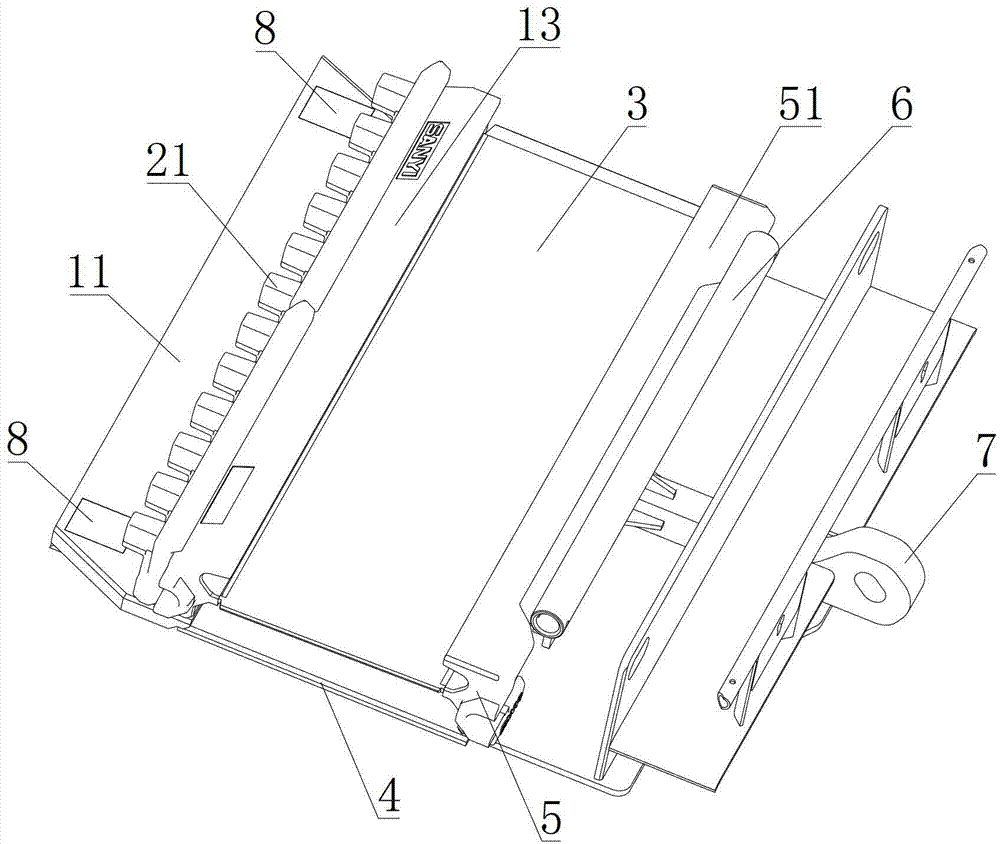

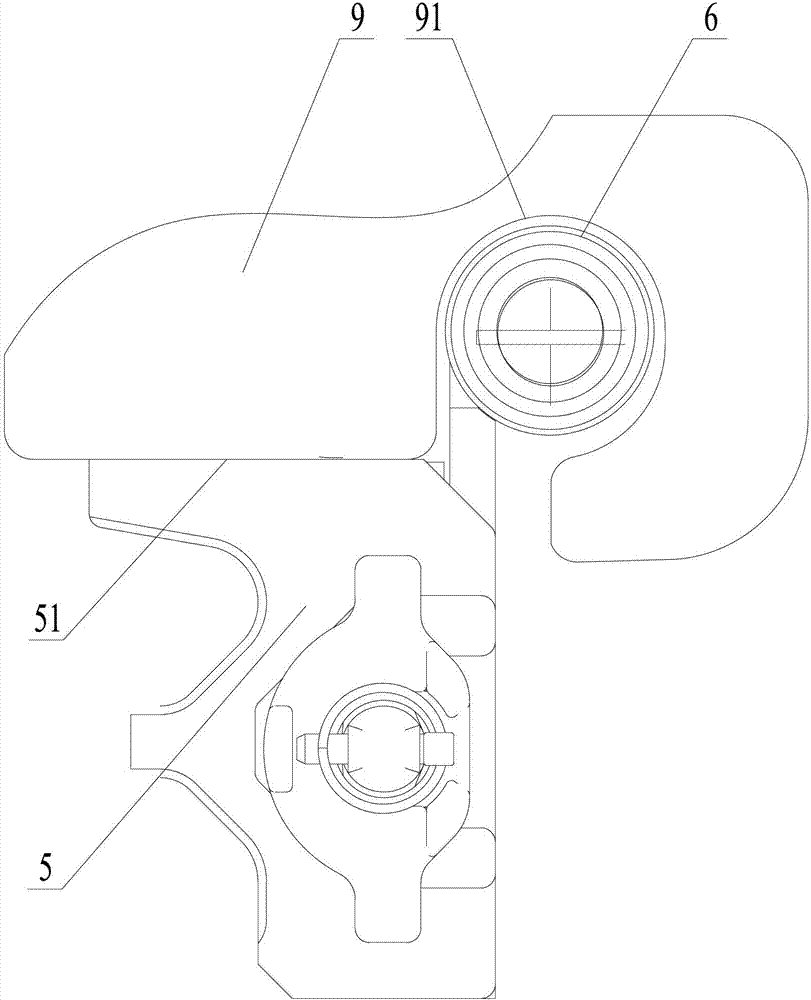

[0021] see figure 1 with figure 2 , shows the structure of the middle trough of the scraper conveyor provided by the present invention. As shown in the figure, the middle trough of the scraper conveyor (hereinafter also referred to as the middle trough) at least includes: a blade groove side 1, a baffle groove Help 5, middle plate 3, bottom plate 4 and pin track 2.

[0022] Wherein the scraping plate groove side 1 comprises a blade plate 11 and a groove side body 13 connected together. The baffle groove side 5 is connected with the connecting ear seat 7 . The middle plate 3 is connected between the groove side 1 of the blade and the groove side 5 of the baffle plate. The bottom plate 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com