Physical purification device for boarding machine oil smoke

A technology for physical purification and engine oil, which is used in combination devices, chemical instruments and methods, and dispersed particle separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

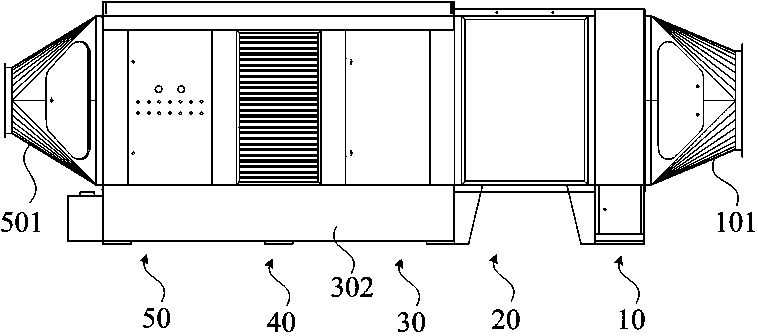

[0033] refer to figure 1 The overall structure schematic diagram of the present invention shown.

[0034] The embodiment of the present invention includes a hair removal system 10 , a cooling and cooling system 20 , an emulsification spraying system 30 , a water and mist removal system 40 , and an electrostatic purification system 50 that are connected together.

[0035] The hair removal system 10 inputs the fume exhaust gas produced by the styling machine through the horn uniform air inlet 101, refer to figure 2 A schematic structural view of the hair removal system 10 shown.

[0036] Hair removal system 10 is provided with filter screen 102, and filter screen 102 is also connected with vibrating device 103, and below filter screen 102 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com