Flexible targeting spraying mechanism for orchards

A spray mechanism and flexible technology, which is applied in the field of flexible target spray mechanism in orchards, can solve the problems affecting the overall level of agricultural development, environmental pollution, and difficulty in spraying, so as to improve the utilization rate of pesticides and spray efficiency, improve operation safety, Effect of reducing waste of pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

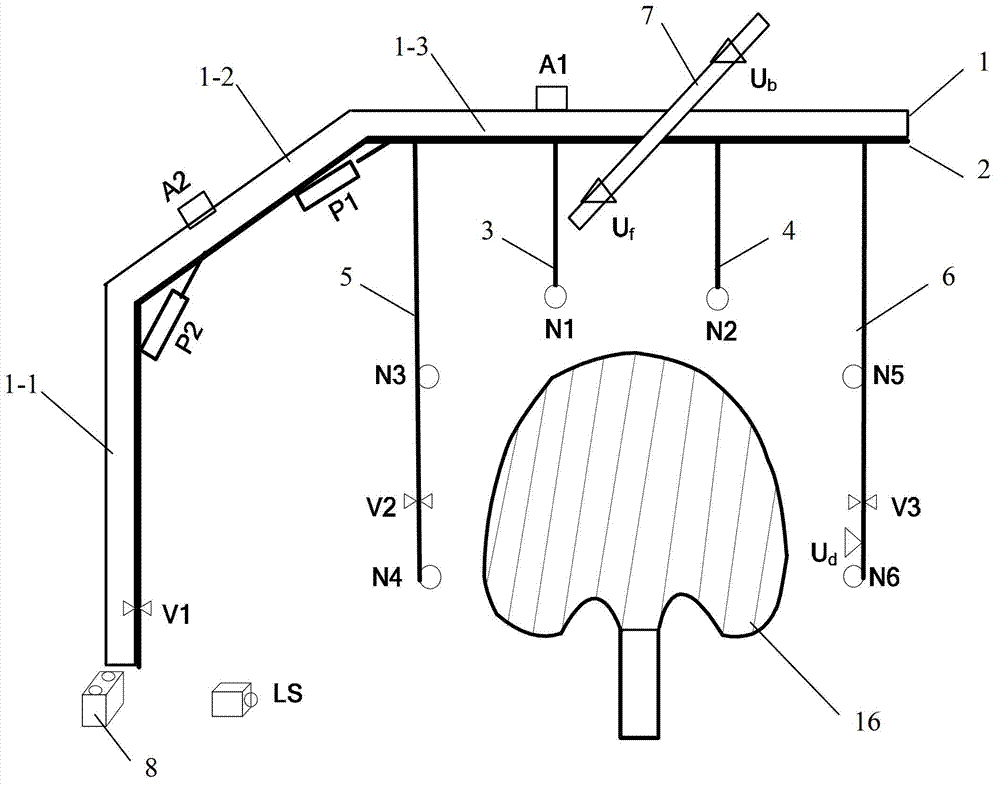

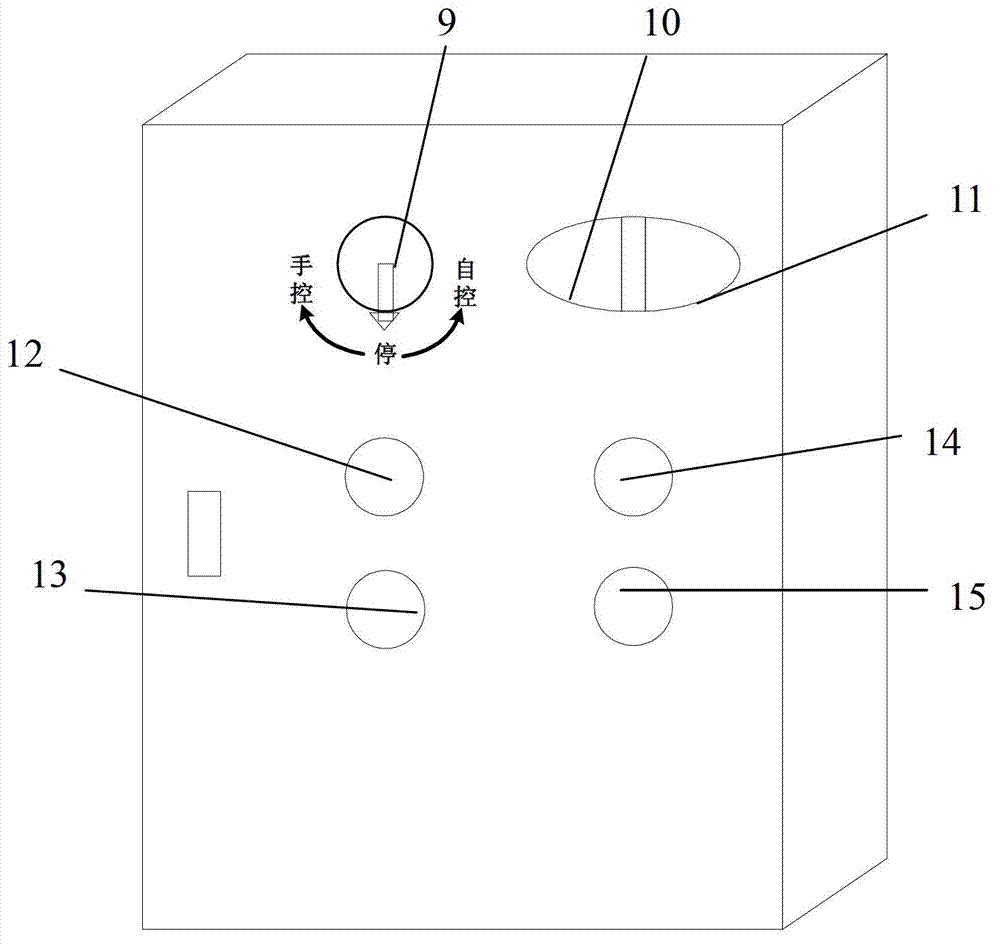

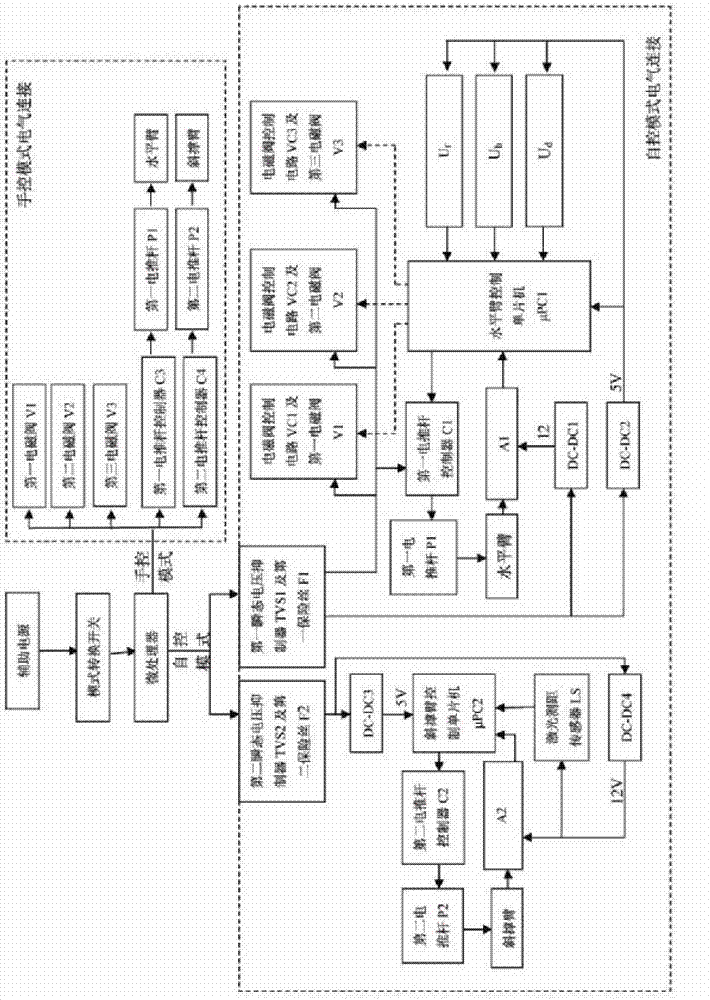

[0041] In this embodiment, a flexible target spraying mechanism for orchards, such as figure 1 As shown, it includes a spray bracket 1, a spray main pipe 2, a spray branch pipe and a control device. The spray bracket is installed on the mobile platform of the spray mechanism, and the spray main pipe is arranged on the spray bracket; The support arm 1-2 and the horizontal arm 1-3, the spraying main pipe correspondingly includes a vertical section, an inclined section and a horizontal section connected in sequence; a plurality of spraying branch pipes are arranged on the horizontal section of the spraying main pipe, and each spraying branch pipe is provided with a nozzle; The first solenoid valve V1 is set on the main pipe, the first electric push rod P1 is set at the junction of the horizontal arm of the spray bracket and the diagonal arm, and the second electric push rod is set at the junction of the diagonal arm of the spray bracket and the telescopic arm P2, the first soleno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com