Test simulation system and test simulation method of safety air bag controller

A technology for controller testing and airbags, applied in electrical testing/monitoring and other directions, can solve the problems of inability to produce acceleration changes, complex mechanical structures, and high testing costs, reducing the number of real vehicle collisions, widening testing conditions, and improving testing. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

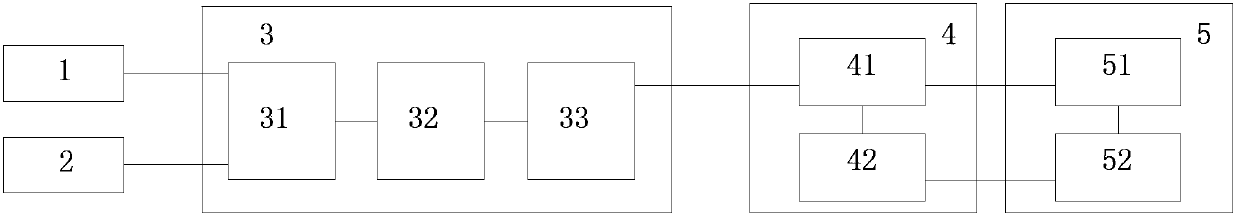

[0021] Such as figure 1 , an airbag controller test simulation system, which is composed of a user operation platform 1, an automobile data recording device 2, a processing host 3, a signal conversion device 4 and an airbag controller 5, and the processing host 3 is provided with sequentially connected file processing Module 31, curve modification module 32 and communication module 33, analog signal output module 41 and analog signal acquisition module 42 are arranged in signal converting device 4, signal processing module 51 and safety airbag ignition module 52 are arranged in airbag controller 5, Wherein, the user operation platform 1 and the vehicle data recording device 2 are respectively connected to the input end of the file processing module 31, and the analog signal output modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com