Photoresist cleaning liquid

A cleaning solution and photoresist technology, applied in the processing of photosensitive materials, etc., can solve the problems of insufficient cleaning ability, wafer pattern and substrate corrosion, etc., and achieve the effect of mild operating temperature and strong removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

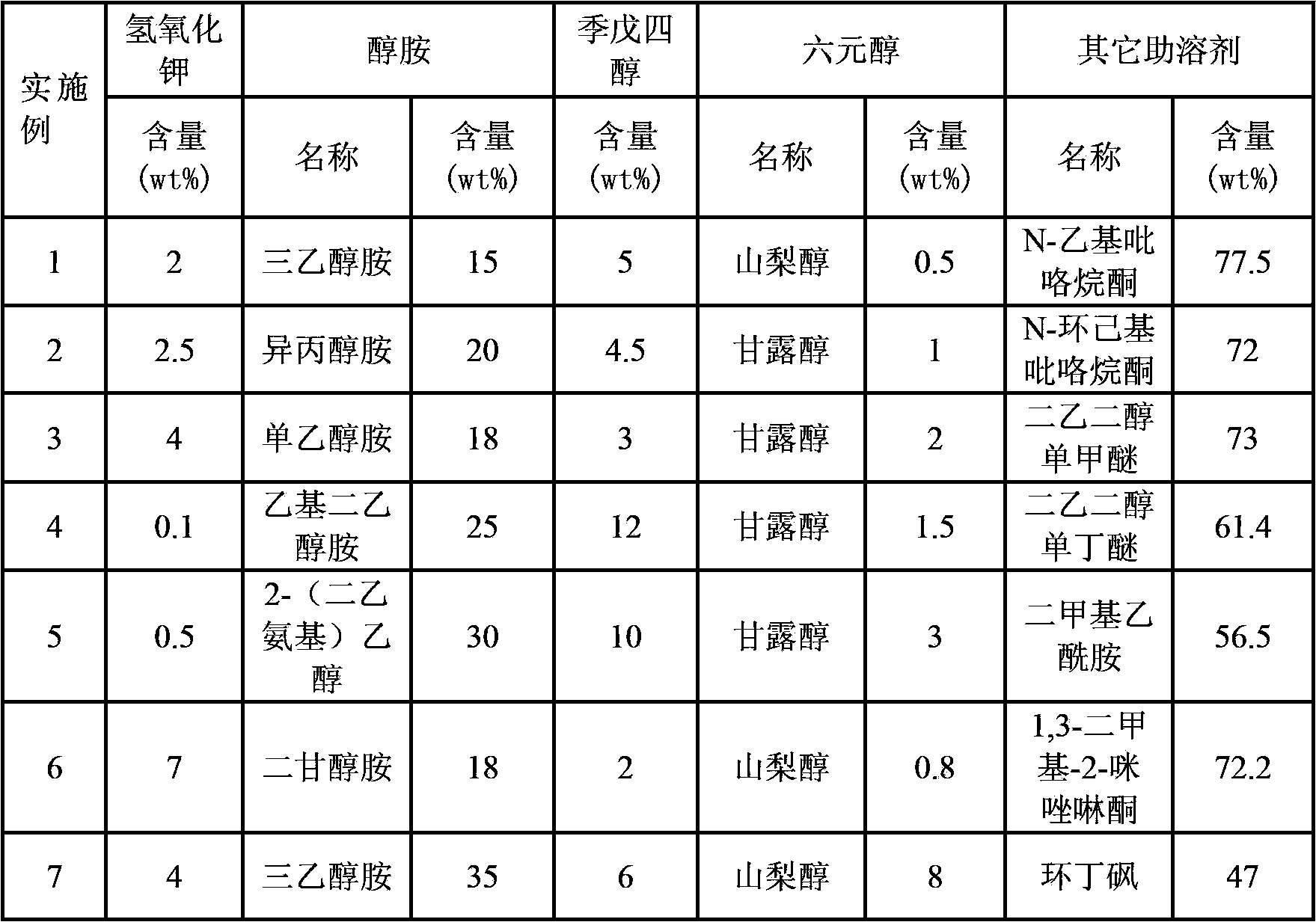

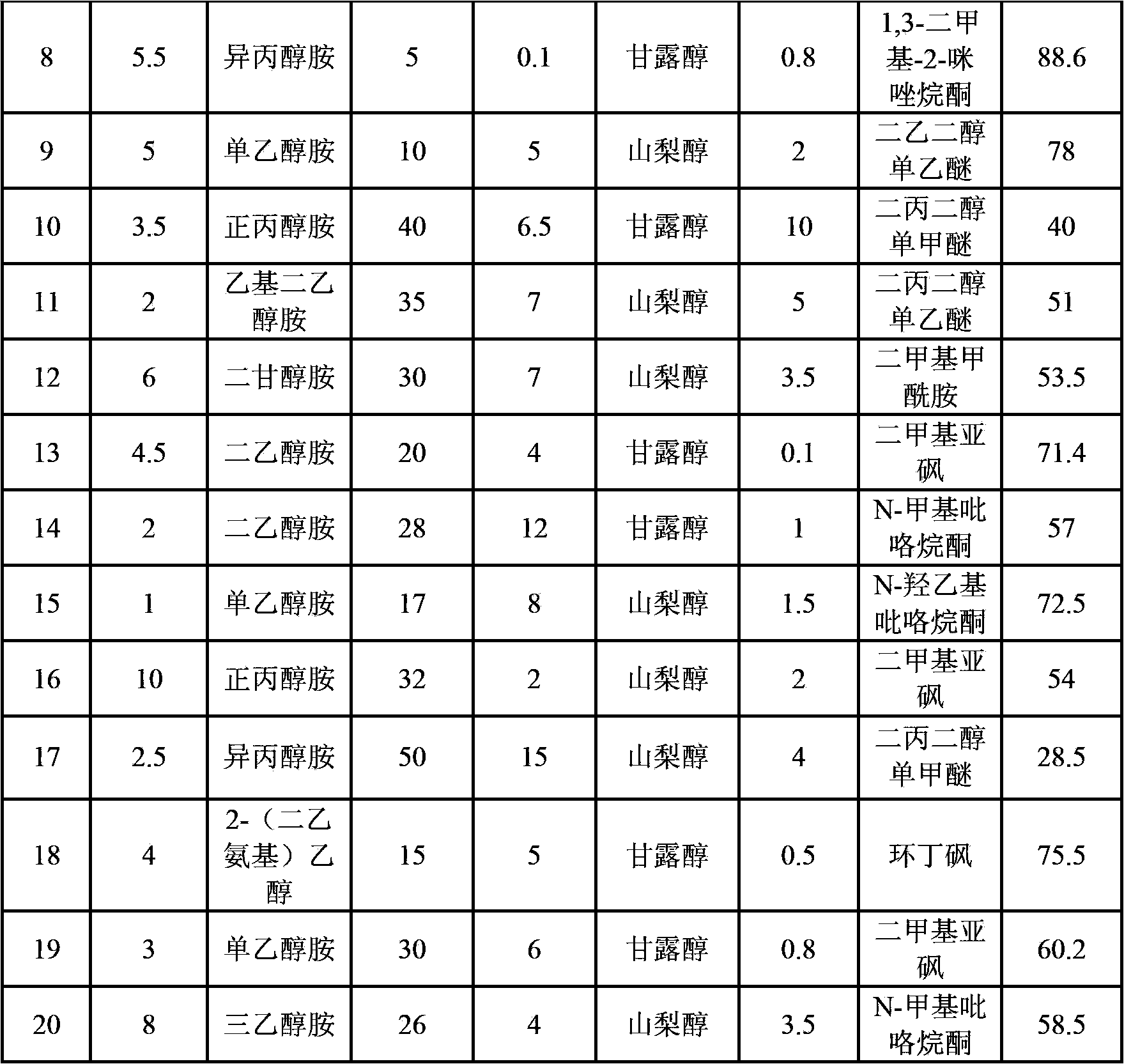

[0021] Prepare the cleaning solution according to the ingredients and proportions of each example in Table 1, and mix them evenly.

[0022] Components and contents of cleaning agents in each example (Examples) of Table 1

[0023]

[0024]

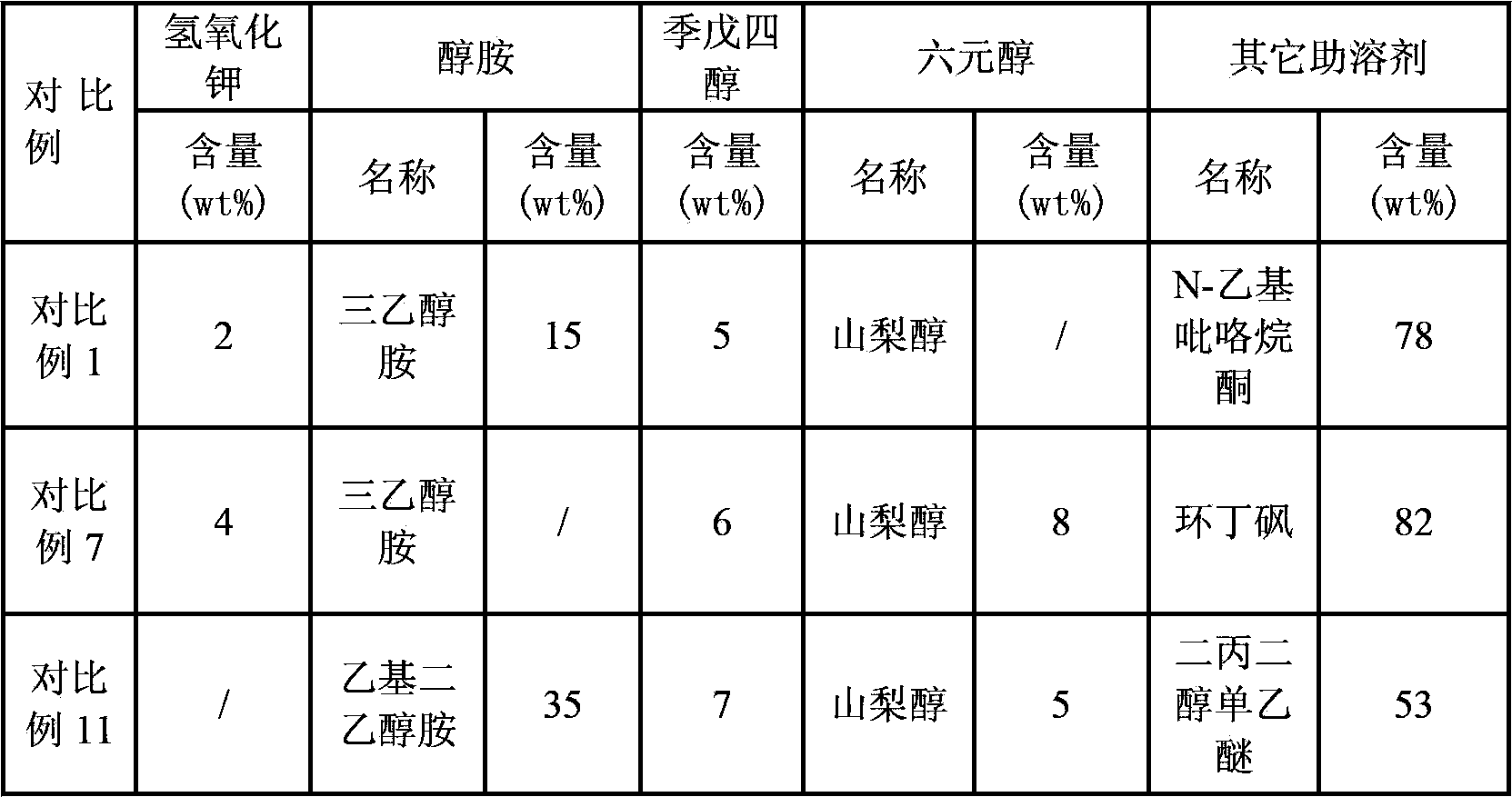

[0025] Component and content of cleaning agent in each comparative example of table 2

[0026]

[0027]

[0028] Wherein, in Comparative Example 7, since no alcohol amine was added, the solution was an incompletely dissolved system.

[0029] In order to further investigate the cleaning situation of this type of cleaning solution, the present invention adopts the following technical means: the wafer containing the positive photoresist (thickness is about 20 microns, and through exposure and etching) is immersed in the cleaning agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com