Temperature measuring rod

A temperature measuring rod and rod body technology, applied in the field of temperature measuring rods, can solve the problems of inserting or taking out the temperature measuring rod, high cost, poor temperature measurement effectiveness, etc., to improve accuracy and work efficiency, flexible on-site application, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

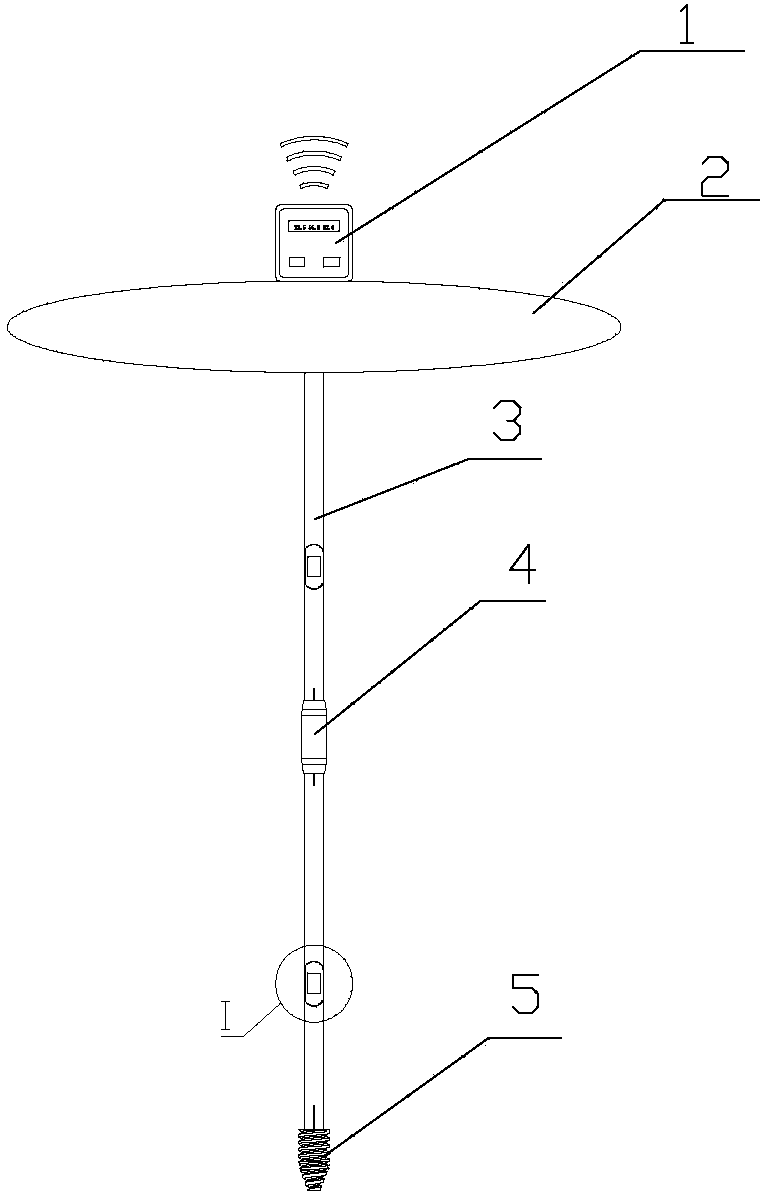

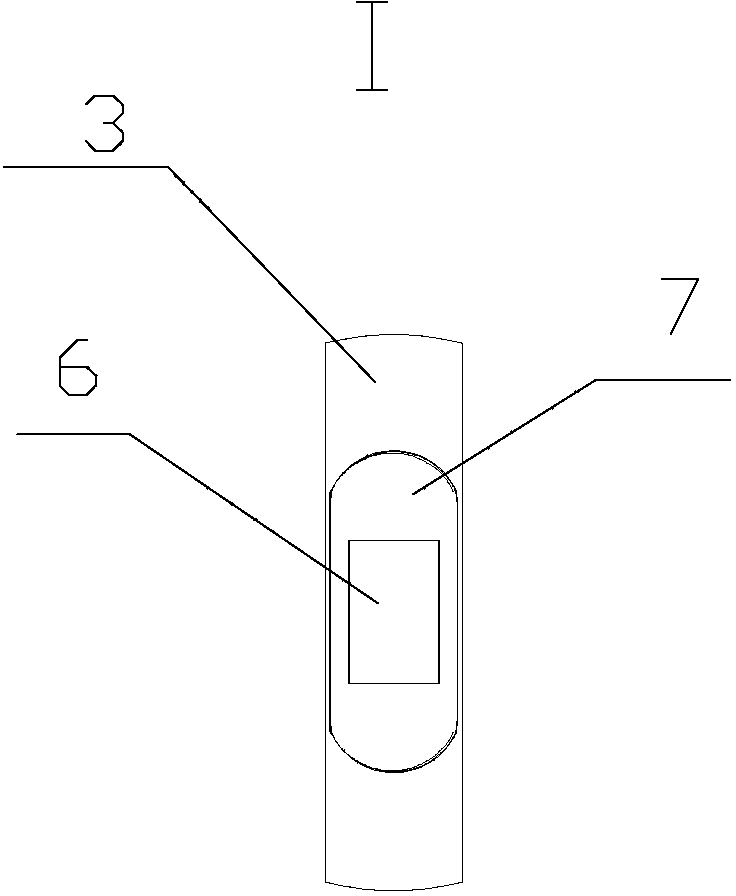

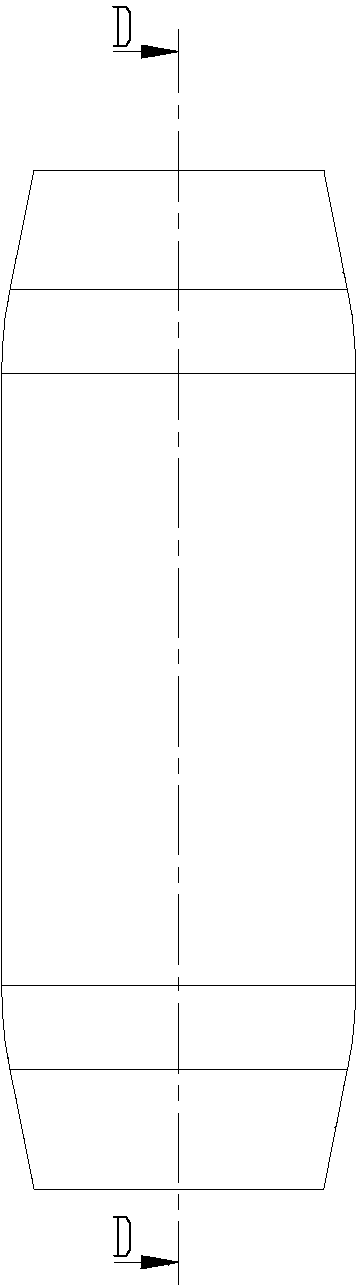

[0024] Such as figure 1 and 2 As shown, the present invention includes a hollow cylindrical rod body 3 . A temperature sensing device is provided on the rod body 3 . The device includes a thermal conductor 6 embedded in the rod body 3 and a temperature sensor placed in the rod body 3 and in close contact with the thermal conductor 6 . The thermal conductor 6 is made of copper with high thermal conductivity. Between the rod body 3 and the heat conductor 6 is provided a heat insulating layer 7 made of extremely low thermal conductivity flame-retardant nylon. Threads and electrical connectors are provided at both ends of the rod body 3 , and the two rod bodies can be cascaded and electrically communicated through the bolt fastening device 4 . A wireless transceiver control terminal 1 electrically connected to the rod body is installed on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com