Vertical water ring vacuum pump

A water ring vacuum pump, vertical technology, applied in the field of vacuum obtaining equipment, can solve the problems of the horizontal water ring vacuum pump, such as bulky body, inconvenient installation and maintenance, and large consumption of raw materials, so as to reduce raw material consumption, facilitate processing and assembly, Effect of manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

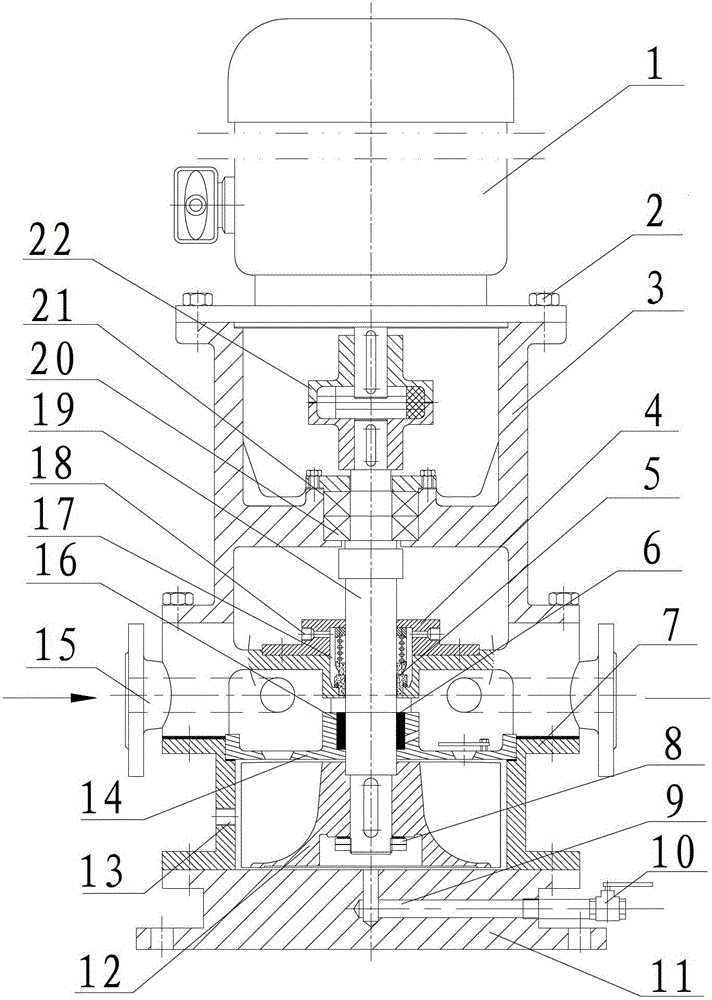

[0021] The invention will be further described below in conjunction with the accompanying drawings.

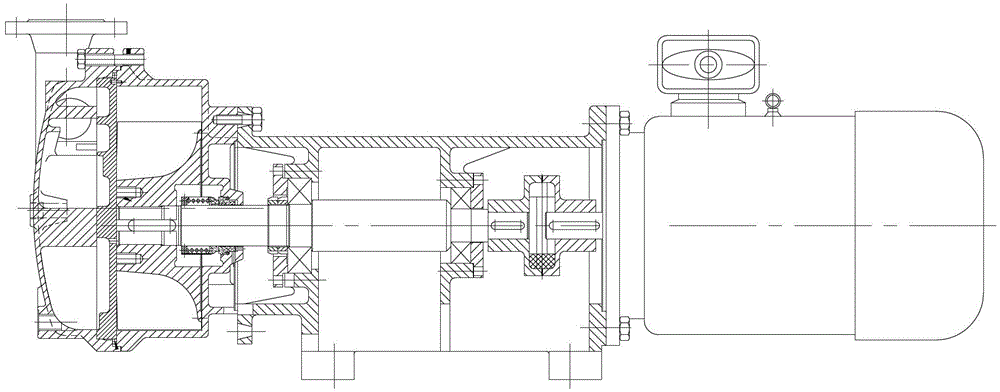

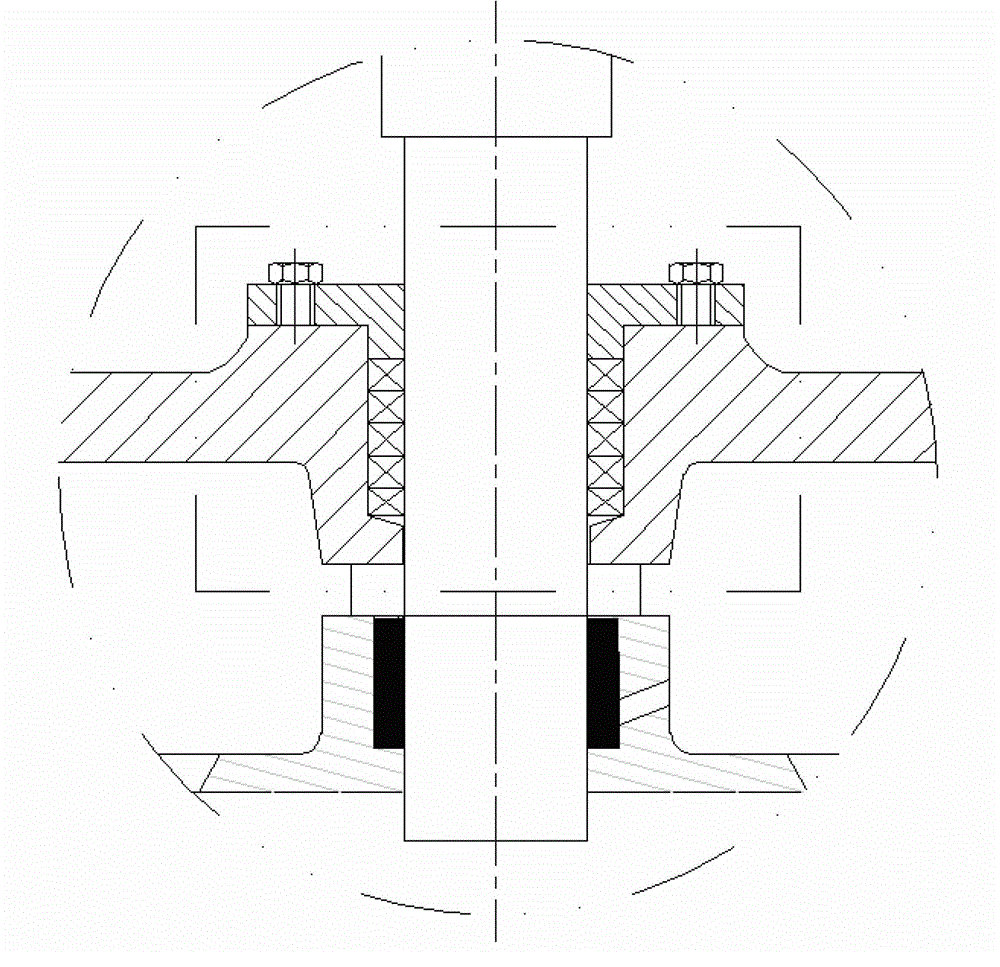

[0022] like figure 2 As shown, the vertical water ring vacuum pump includes a stator part, a rotor part, a bracket 3 and a motor 1 . The stator part includes a base 11 , a pump body 7 , a distribution disc 14 and a pump cover 15 , and the rotor part includes a pump shaft 19 and an impeller 12 . The bottom of the pump body 7 is provided with a base 11, the pump body 7 is fixed on the base 11, the top of the pump body 7 is provided with a pump cover 15, and the outer circular side of the pump body 7 is provided with a liquid inlet 13. The base 11 is provided with a liquid discharge channel 9, and the liquid discharge channel 9 is connected with a liquid discharge valve 10. When the pump is running, the liquid discharge valve 10 is in a closed state. When the pump is shut down, the working fluid remaining in the pump body 7 can be completely drained through the liquid discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com