High-efficiency non-clamping impact-blanking digging method and high-efficiency non-clamping impact-blanking digger

A technology of excavator and blanking mechanism, applied in the field of machinery, can solve the problems of destroying the performance of equipment, reducing the rate of block production, and increasing the running resistance of the impact mechanism, so as to facilitate support operations and reduce the particle size of block , The effect of facilitating the outflow of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

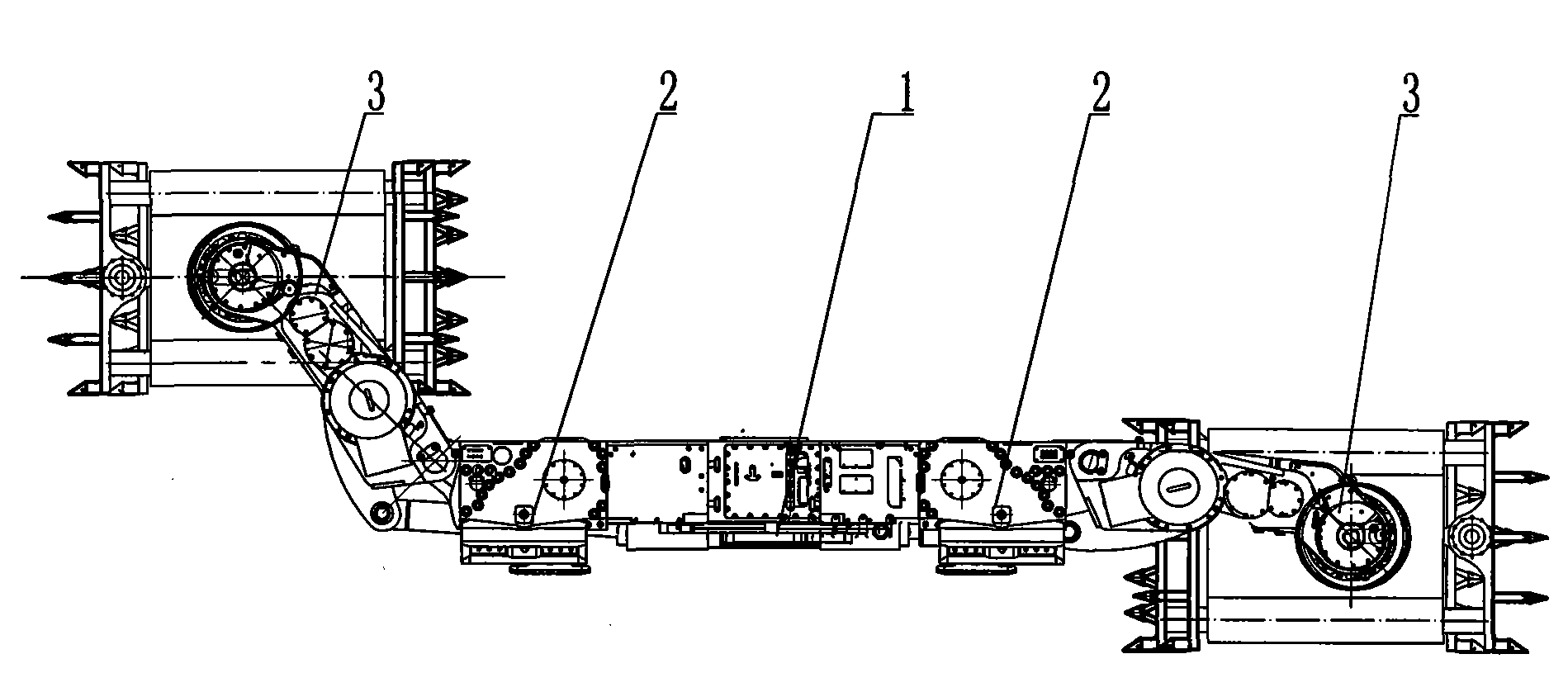

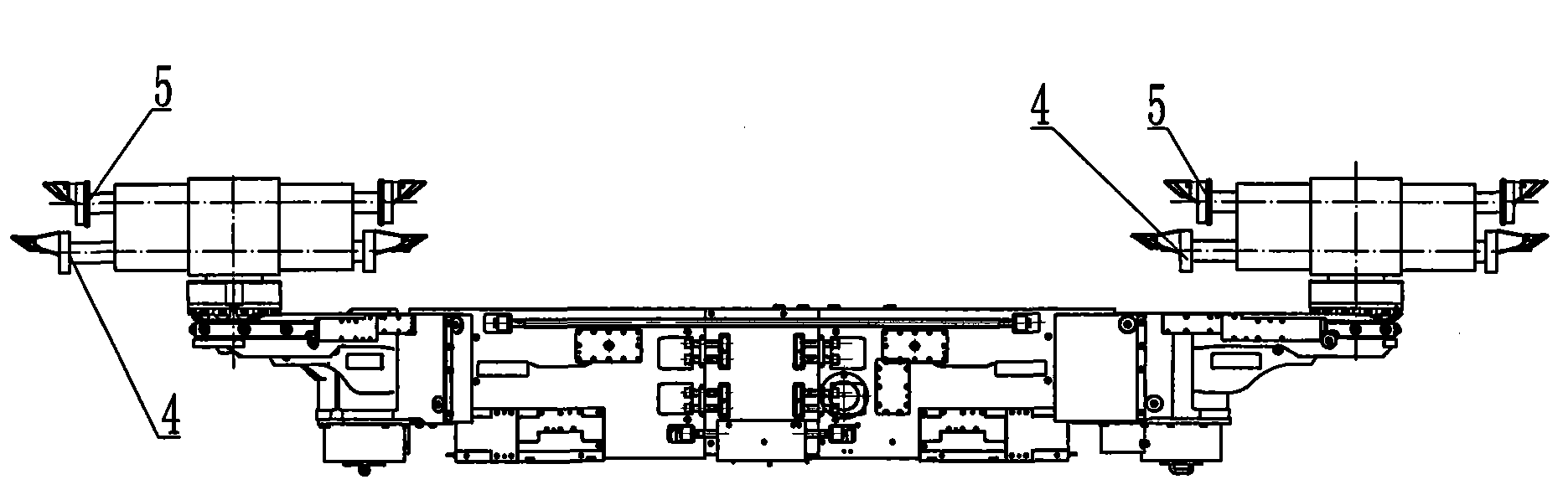

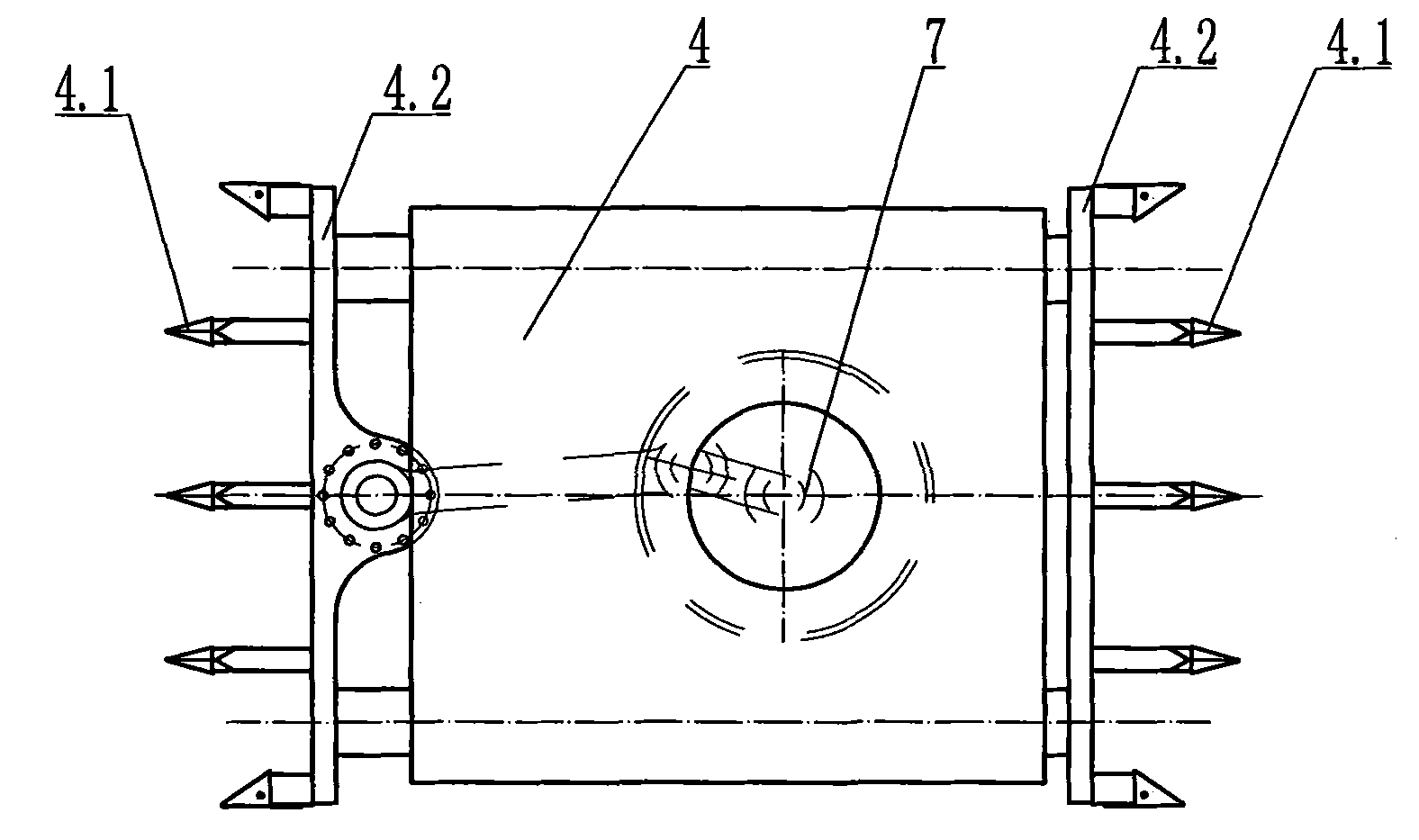

[0089] Such as Figure 1 to Figure 5 As shown, a high-efficiency impact blanking mining machine with no material inclusions and impact blanking method that implements the high-efficiency impact blanking method without inclusions includes a fuselage 1, a traveling mechanism 2, an impact blanking mechanism 3, etc., and the traveling mechanism 2 is arranged on the bottom of the fuselage 1 The front and rear parts, etc., the impact blanking mechanism 3 is connected with the fuselage 1, the impact blanking mechanism 3 includes the outer layer material punching mechanism 4 and the inner layer material punching mechanism 5, etc., the outer layer material punching mechanism 4 and the inner layer material punching mechanism Mechanism 5 is arranged close to, and the punching outer layer material mechanism 4 includes punching outer layer material teeth 4.1 etc., and the punching inner layer material mechanism 5 includes punching inner layer material teeth 5.1 etc., and the setting of punc...

Embodiment 2

[0102] Such as Figure 6 to Figure 9 As shown, a high-efficiency impact blanking mining machine with no material inclusions and impact blanking method that implements the high-efficiency impact blanking method without inclusions includes a fuselage 1, a traveling mechanism 2, an impact blanking mechanism 3, etc., and the traveling mechanism 2 is arranged on the bottom of the fuselage 1 The front and rear parts, etc., the impact blanking mechanism 3 is connected with the fuselage 1, the impact blanking mechanism 3 includes the outer layer material punching mechanism 4 and the inner layer material punching mechanism 5, etc., the outer layer material punching mechanism 4 and the inner layer material punching mechanism Mechanism 5 is arranged close to, and the punching outer layer material mechanism 4 includes punching outer layer material teeth 4.1 etc., and the punching inner layer material mechanism 5 includes punching inner layer material teeth 5.1 etc., and the setting of punc...

Embodiment 3

[0111] Such as Figure 10 to Figure 15 As shown, a high-efficiency impact blanking mining machine with no material inclusions and impact blanking method that implements the high-efficiency impact blanking method without inclusions includes a fuselage 1, a traveling mechanism 2, an impact blanking mechanism 3, etc., and the traveling mechanism 2 is arranged on the bottom of the fuselage 1 The front or the rear or the bottom, etc., the impact blanking mechanism 3 is connected with the fuselage 1, the impact blanking mechanism 3 includes the outer layer material punching mechanism 4 and the inner layer material punching mechanism 5, etc., the outer layer material punching mechanism 4 and the inner layer material punching mechanism The layer material mechanism 5 is arranged close to, and the punching outer layer material mechanism 4 includes punching outer layer material teeth 4.1 etc., and the punching inner layer material mechanism 5 includes punching inner layer material teeth 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com