Coiled tubing locking device

A coiled tubing and anti-loosening technology, which is applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of coiled tubing that cannot be neatly and tightly discharged drums, cannot be used normally, and staggered coiled tubing, etc., to achieve effective anti-loosening control, Wide range of uses, the effect of preventing chaos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

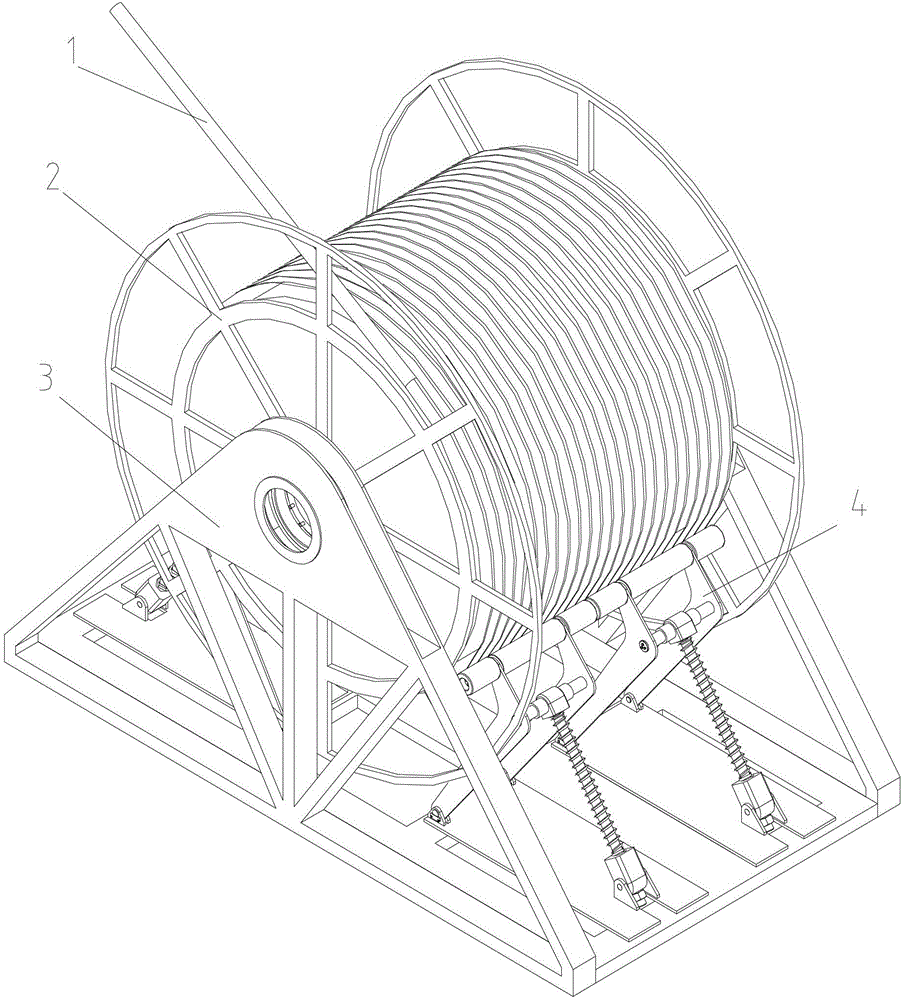

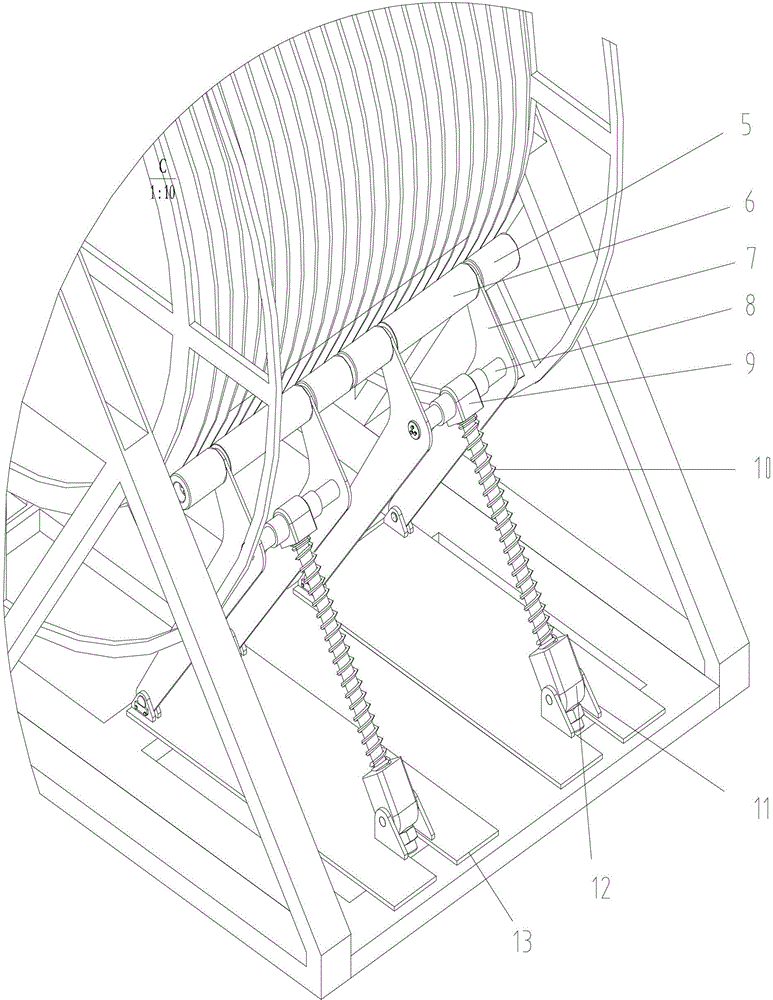

[0024] like figure 1 and figure 2 As shown, a coiled tubing anti-loosening device of the present invention includes a coiled tubing 1, a drum 2 and a drum support base 3, the drum support base 3 is pierced with a drum 2, and the coiled tube 1 is installed on the drum 2, and the support base The bottom surface of 3 is provided with an anti-loosening mechanism 4, and the anti-loosening mechanism 4 cooperates with the roller 2 and compresses the continuous pipe 1. The anti-loosening mechanism 4 can effectively prevent the coiled tubing 1 from loosening, and the number of the anti-loosening mechanisms 4 can be increased or decreased according to the width of the roller 2. The whole mechanism has four anti-loosening devices 4 symmetrically distributed on both sides of the drum 2, respectively.

[0025] The anti-loosening mechanism 4 in the present embodiment comprises a backing plate 13, and the two ends of the backing plate 13 are all fixed on the bottom surface of the support b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com