Construction method for recombinant strain producing L-glutamic oxidase and applications of the recombinant strain

A technology of glutamate oxidase and recombinant strains, applied in the fields of genetic engineering and enzymology, and can solve problems such as inactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

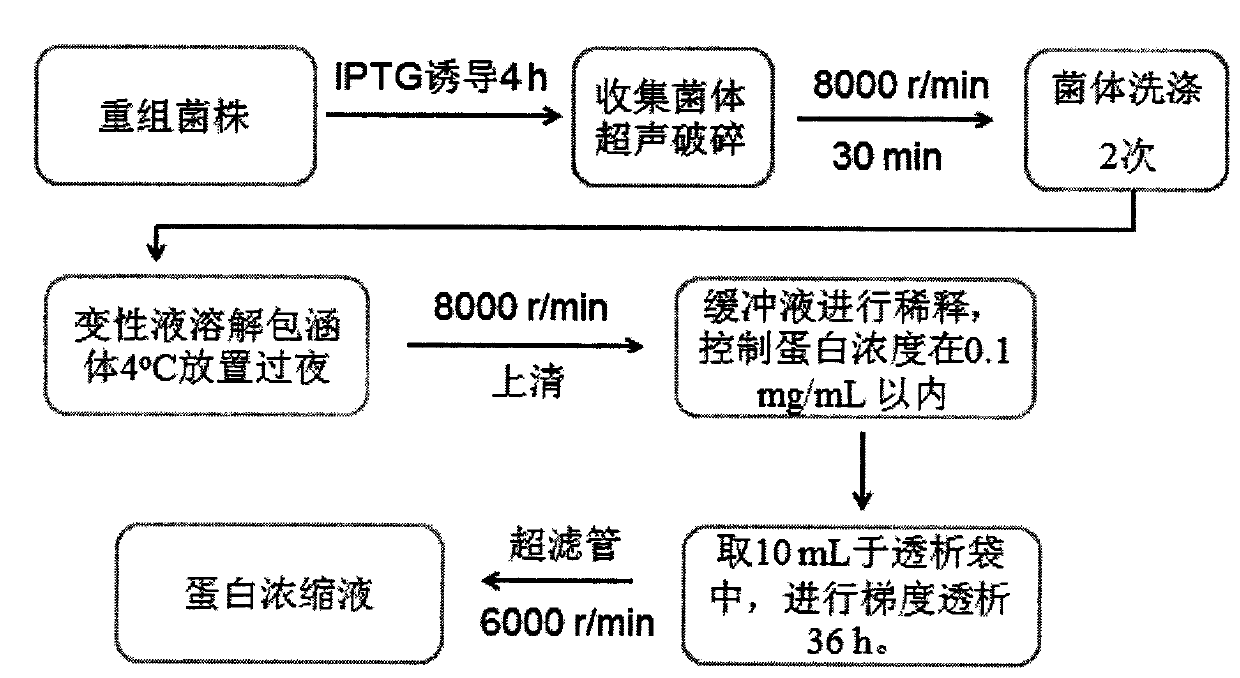

Method used

Image

Examples

Embodiment Construction

[0020] 1. Construction of recombinant strains:

[0021] 1) Use primer 1: 5'CATGCCATGGCAATGACTGAAGATCACGCGG3' and primer 2: 5'CCCAAGCTTGCGCTGTGTGGATCTCCAAG3' to perform PCR amplification on the gene group (NCBI sequence number: EFE71695.1) from Streptomyces ghanaensis ATCC14672: add LA taq enzyme to the system, 95°C Pretreatment for 9min, melting at 95°C for 30s, annealing at 65°C for 30s, extension at 72°C for 2.2min, 30 cycles;

[0022] 2) Digest the target gene and expression vectors pET20b and pET28a with restriction endonucleases Nco I and HindIII at 37°C for 2 hours;

[0023] 3) Use T4 ligase to ligate the digested target gene and plasmids pET20b and pET28a at 16°C for 10 h, transfer them into the expression strain E.coli BL21 by chemical transformation, and smear them on LB plates containing ampicillin and kanapenicillin Medium culture for 12h;

[0024] 4) Perform PCR and enzyme digestion verification on the colonies grown on the plate, perform sequencing verification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com