Portable pre-stressed tensioning jack

A tension jack and prestressing technology, applied in the direction of lifting devices, etc., can solve the problems of inconvenient carrying and consumption of industrial energy, and achieve the effects of simple processing, steel saving and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

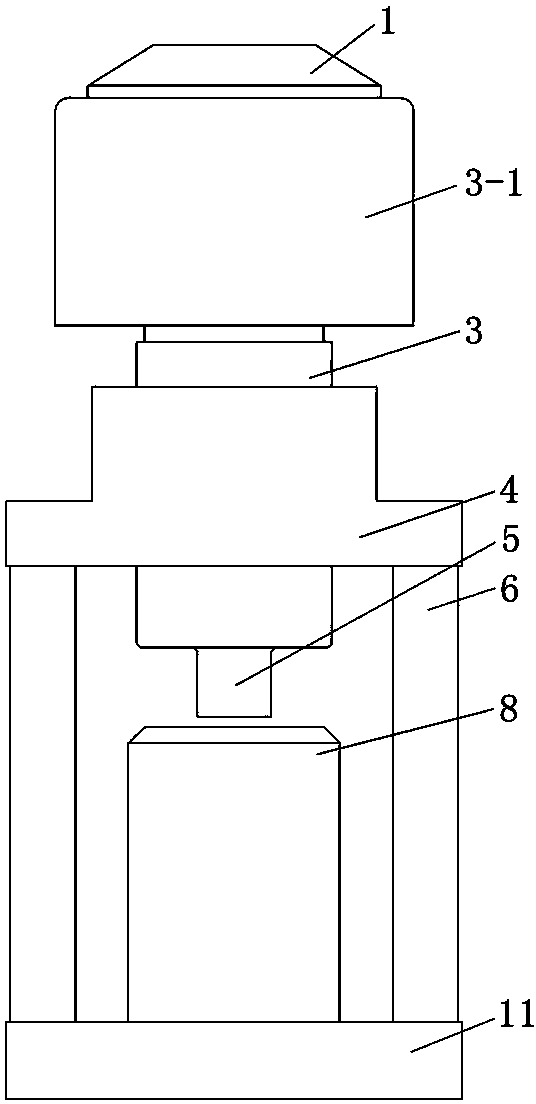

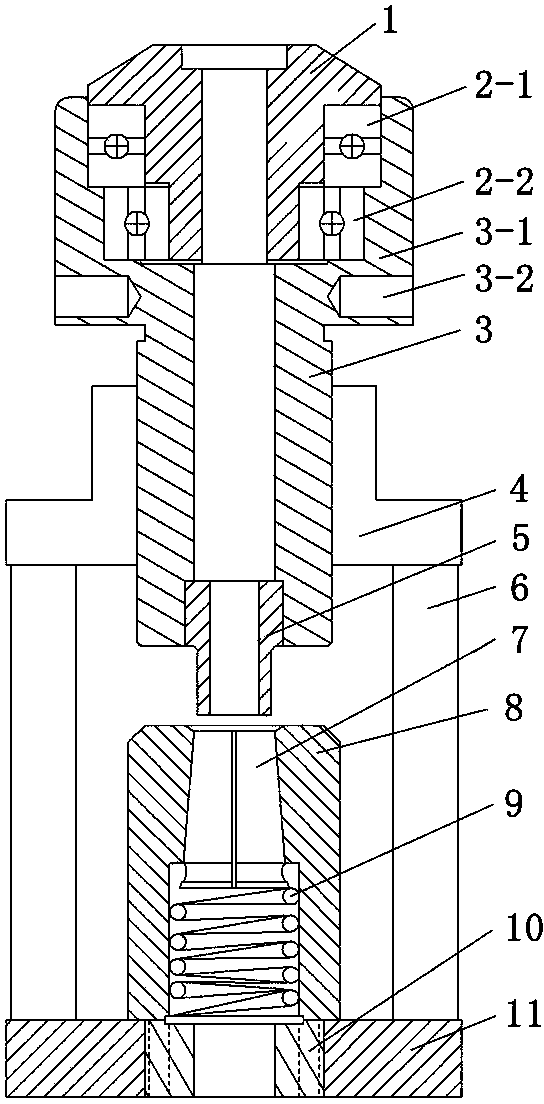

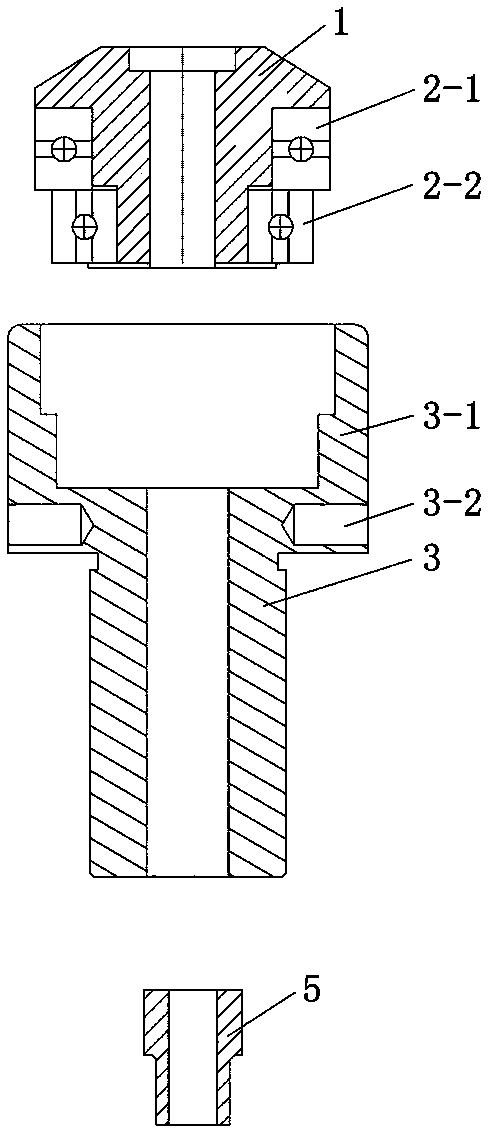

[0016] figure 1 and figure 2 The shown portable prestressed tension jack mainly includes a fixed part and a rotating part; the fixed part includes a base 11 and a fixed nut 4, and the base 11 and the fixed nut 4 are connected and fixed by a plurality of connecting rods 6, and the middle part of the base 11 is installed with Piercing sleeve 8, the piercing sleeve 8 is arranged between the base 11 and the fixed nut 4, a section of the inner cavity of the piercing sleeve 8 is a taper hole, the small end of the taper hole is far away from the base 11, and a tool is clamped in the taper hole The clip 7 and the tool clip 7 can be replaced according to the specifications of different types of steel strands on the construction site. The inner cavity of the bushing 8 is equipped with a spring 9 that presses the big end of the tool clip 7, and the spring 9 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com