Boeing aircraft airtight support plate nut installation process device and process

A pallet nut and installation process technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as large errors and inaccuracy, leakage of pressurized gas or liquid, time-consuming and labor-intensive efficiency, etc., to ensure quality, improve The effect of processing efficiency and guaranteeing reference accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

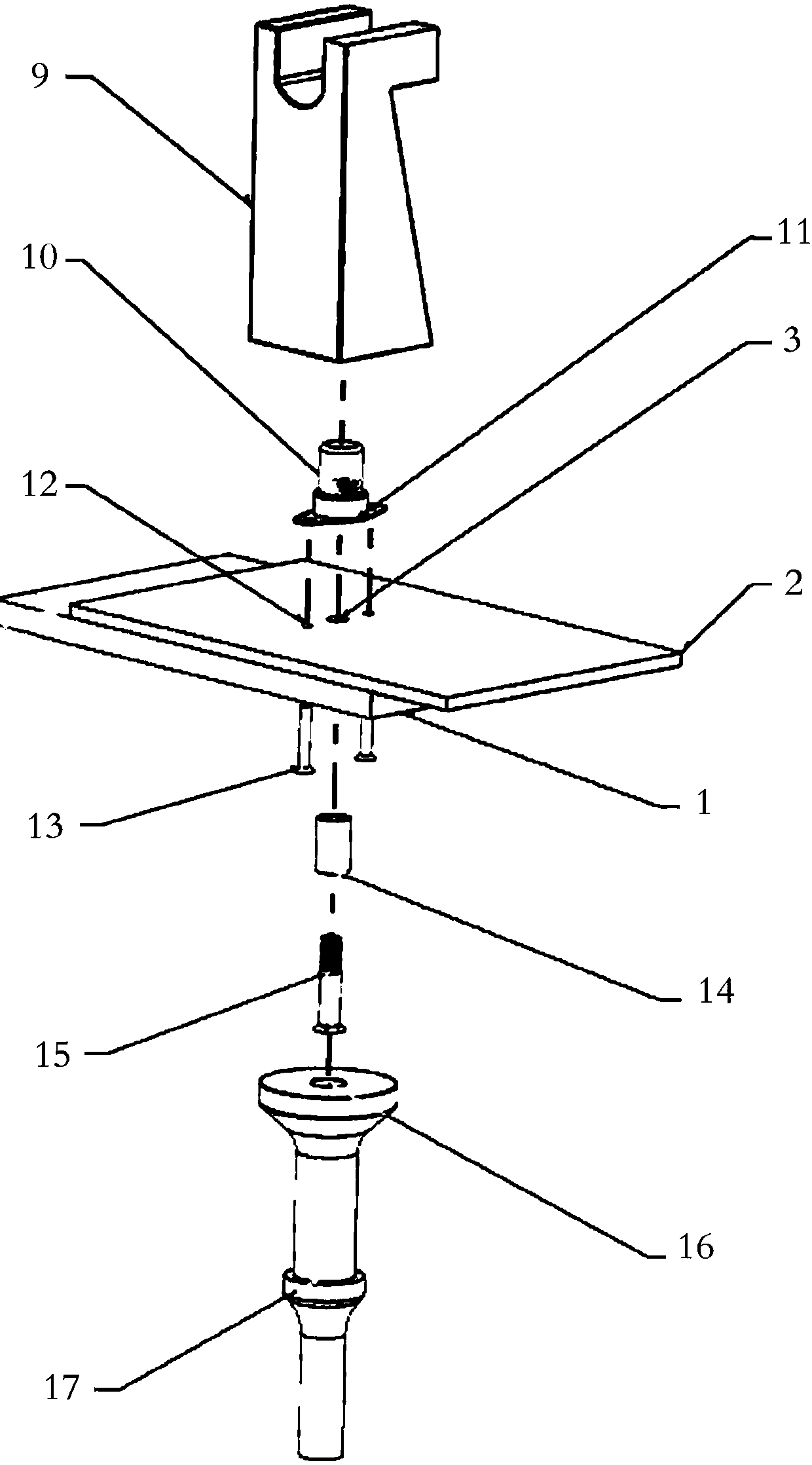

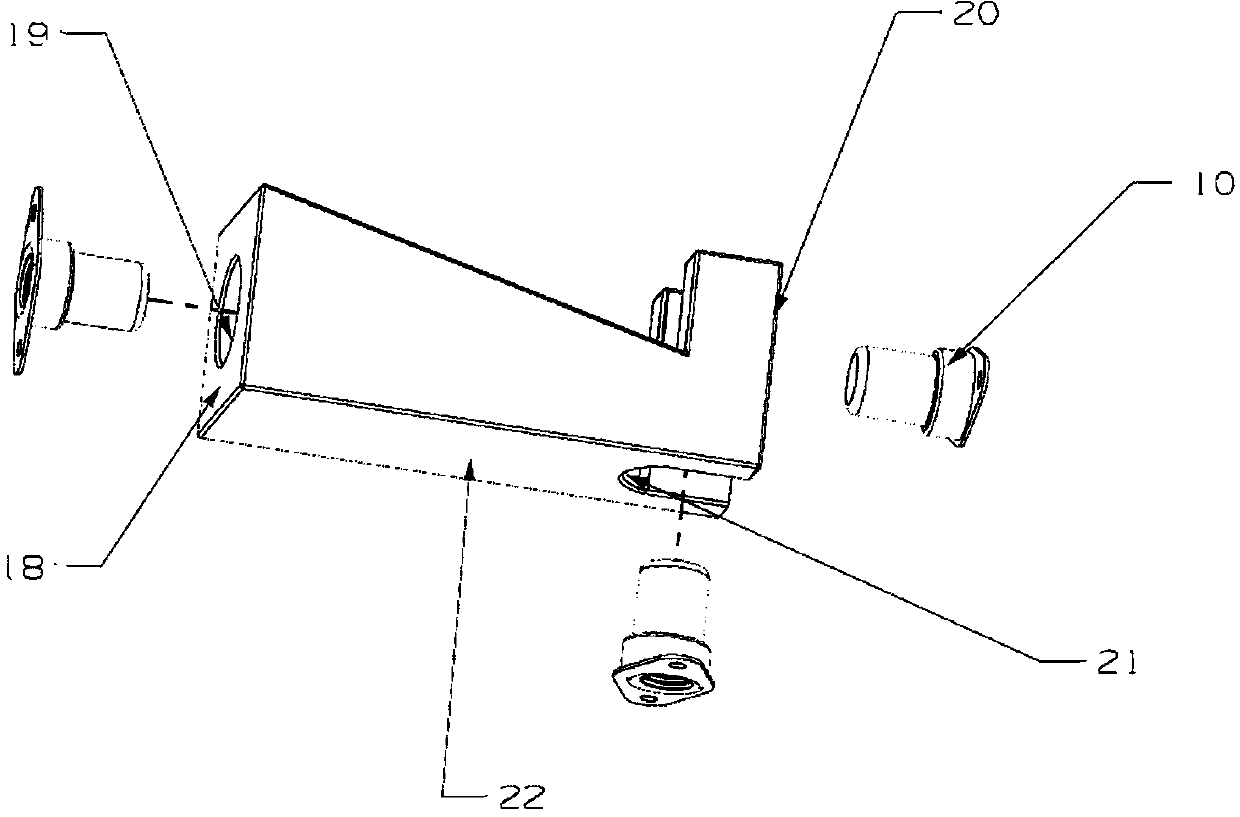

[0036] Refer to the attached figure 1 , involving the first process component used for accurate drilling, which can guide the drill bit for drilling to ensure the positional accuracy between the formed hole and the screw hole 3, where the formed hole is on the skin, Such as figure 1 Proximal Skin 2 and Distal Skin 1 superposition shown in .

[0037] It should be understood that the proximal end refers to the orientation of the airtight support nut 10 , the side of the airtight support nut 10 is the proximal end, and the opposite orientation is the distal end.

[0038] The screw hole 3 in this article refers specifically, that is, the screw hole 3 on the skin that matches the airtight support plate nut 10, such as figure 1 with 2 shown.

[0039] figure 1 The drilling tooling in is vertical hole guide 7, and its main body is a cuboid structure, has a pair of satellite guide holes 6 above, is used for drilling pin guide.

[0040] As for the satellite holes, it should be und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com