Automatic winder mechanism for zipper webbing loom cloth tape

A technology of nylon cloth tape and automatic tape winding, which is applied in the directions of winding strips, transporting and packaging, and sending objects. Reduce the labor intensity of operation, reduce the labor intensity of work, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

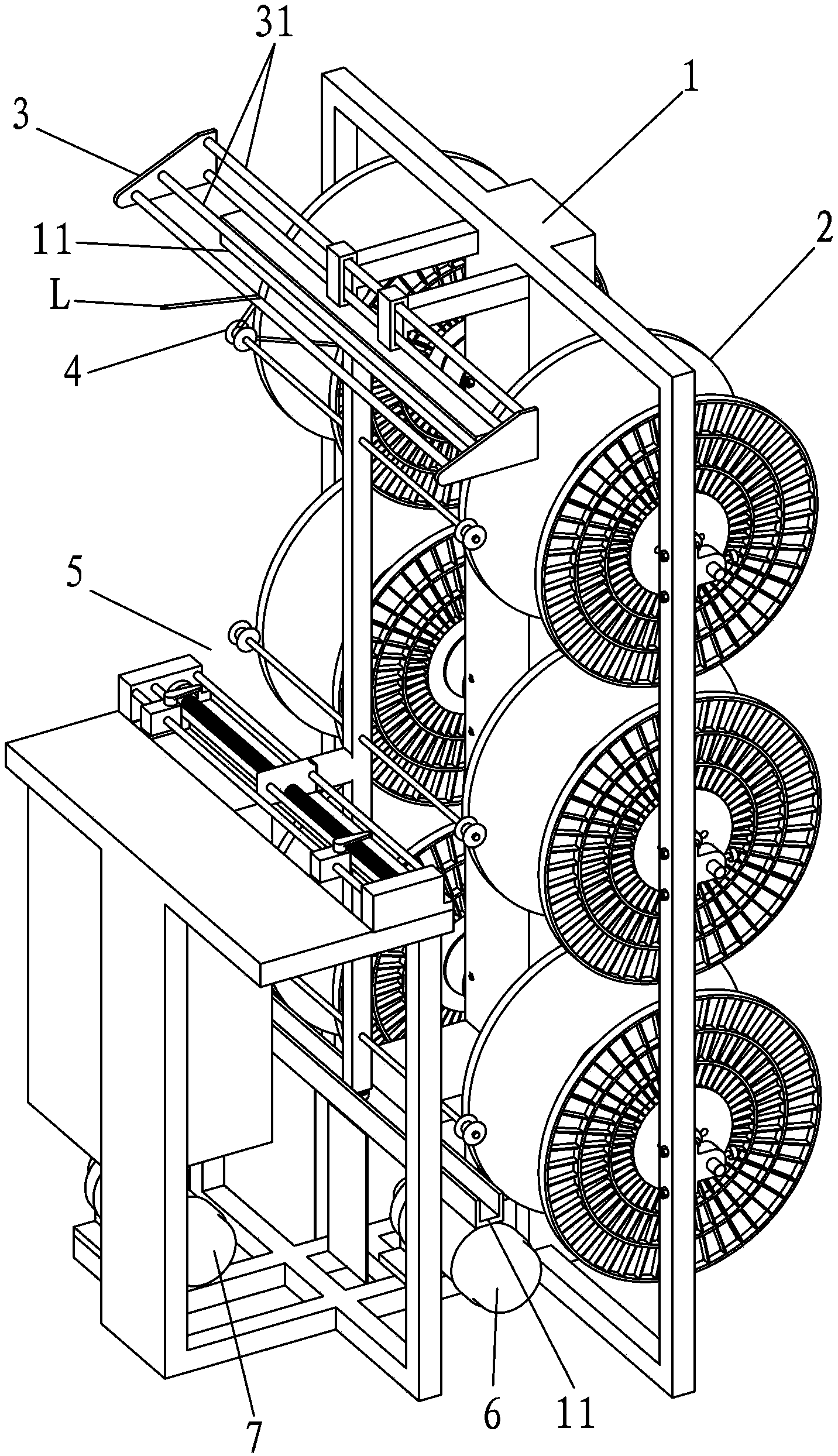

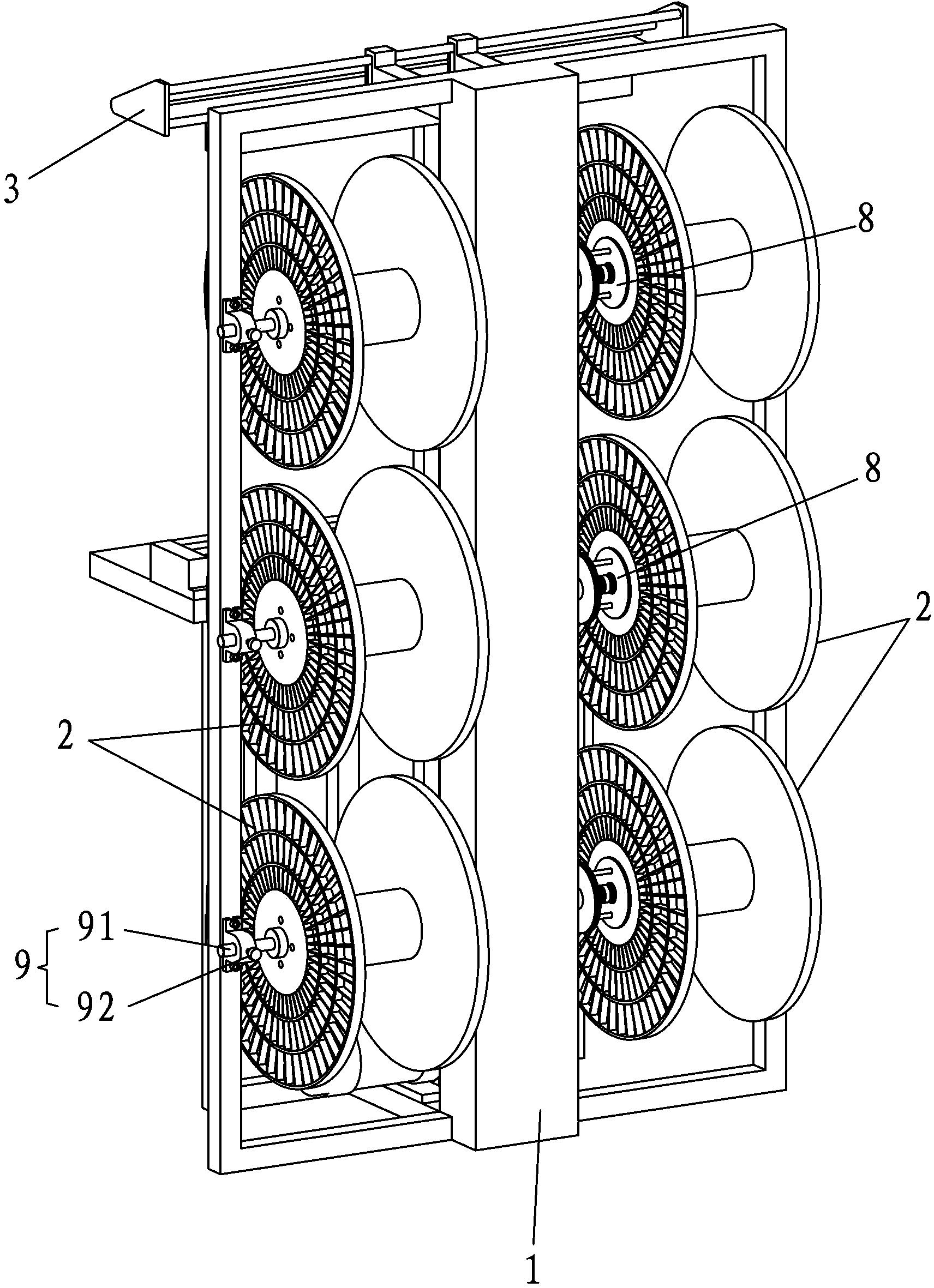

[0048] The invention relates to an automatic winding device for nylon cloth tape of a zipper weaving machine, such as Figure 1-5 As shown, it mainly includes a bracket 1, a reel 2, a guide wheel 4 and a travel mechanism 5.

[0049] Such as Figure 1-2 As shown, the reel 2 is installed on the support 1, and the rotation axis of the reel 2 extends along the horizontal direction. In a given preferred embodiment, several reels 2 are provided, and the several reels 2 are divided into two groups arranged side by side, and the reels in each group are arranged vertically. Each reel 2 is connected to the reel motor 6 through a sprocket and a chain (the sprocket and chain are installed inside the frame 1, not shown in the figure), and the reel motor 6 drives each reel 2 to rotate .

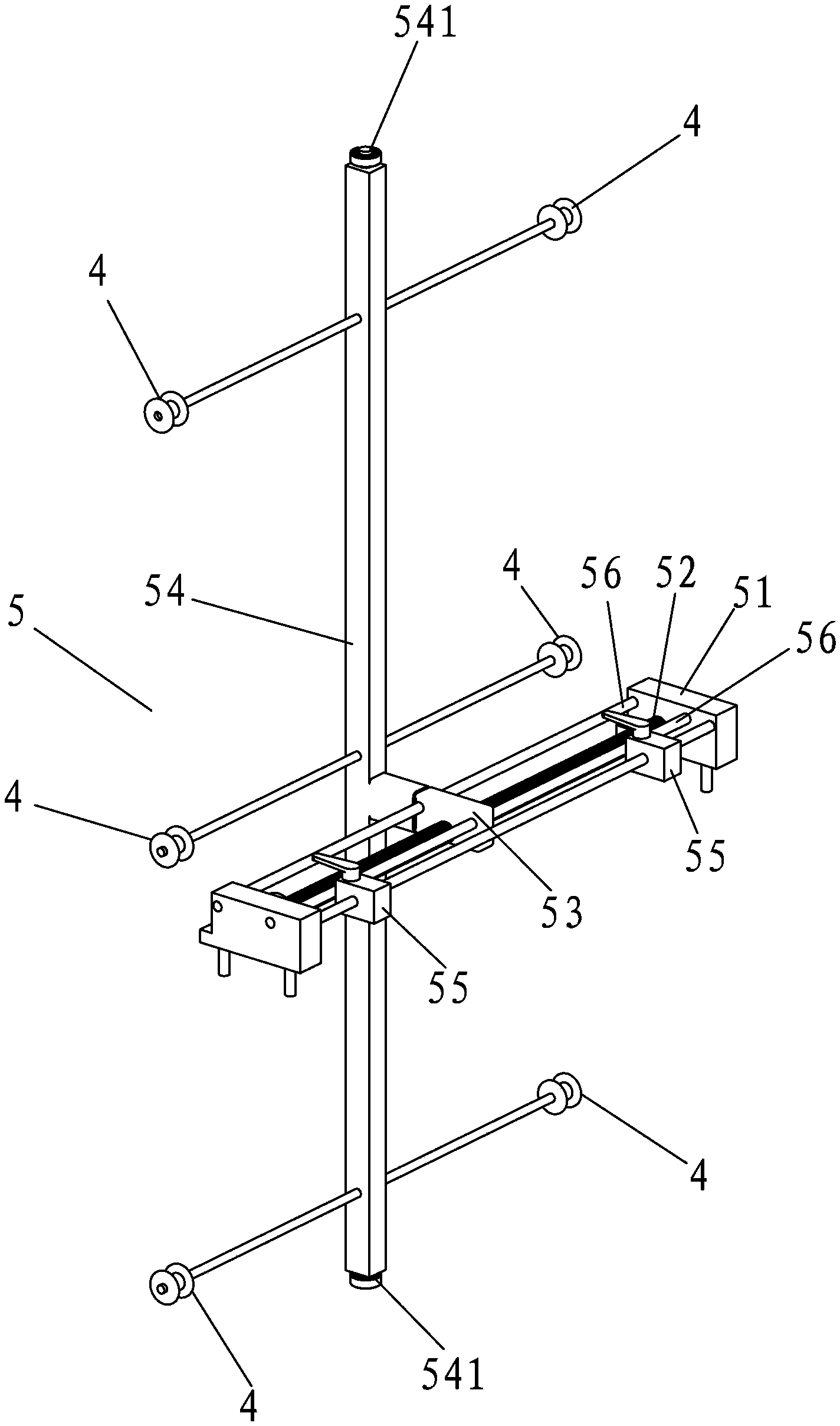

[0050] The travel mechanism 5 is installed in front of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com