Concrete precast pile stream curing pool

A technology of concrete prefabricated piles and steam curing, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., and can solve problems such as affecting the placement of pool covers, steam leakage, and deformation of water-sealed tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

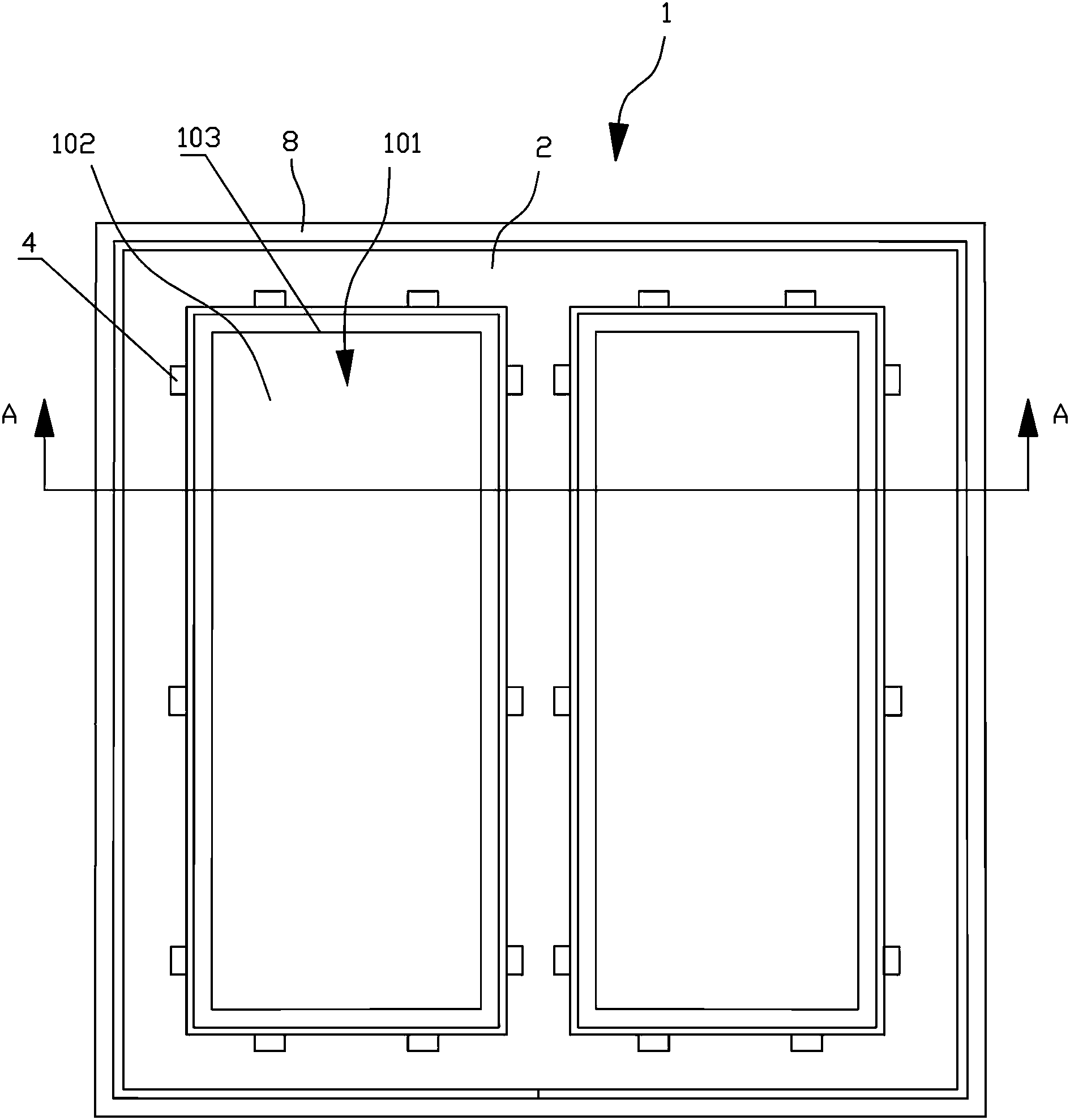

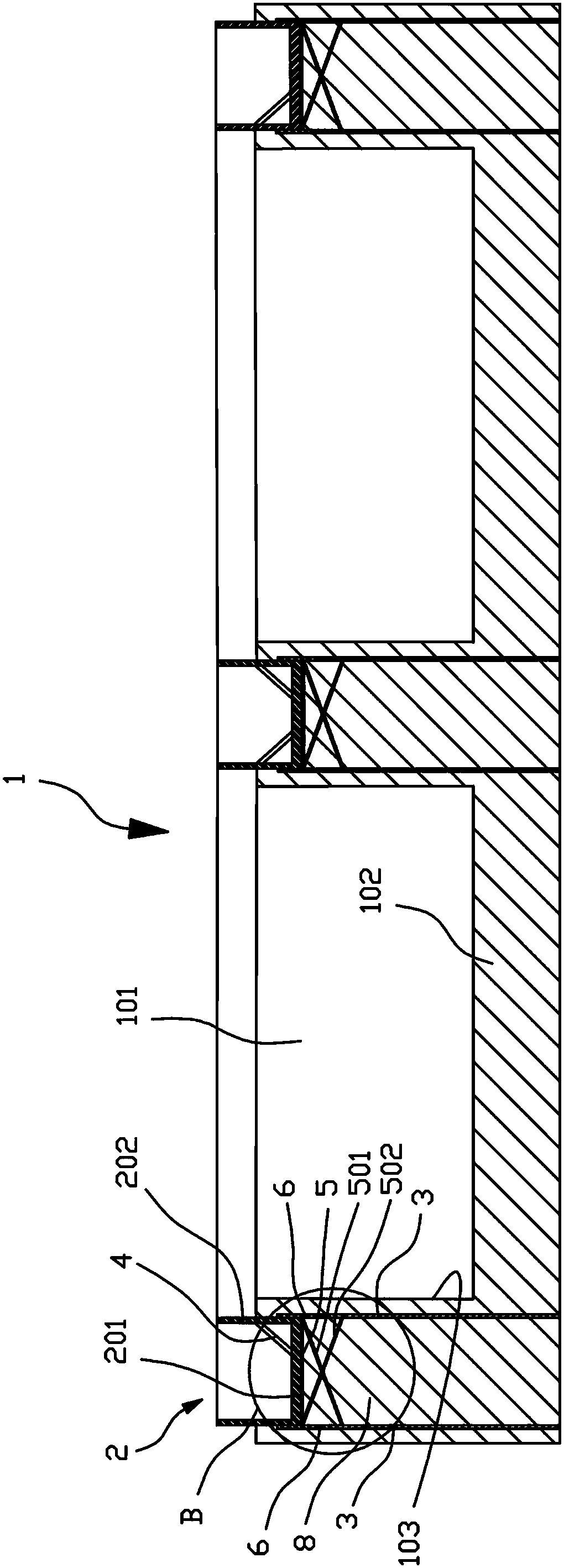

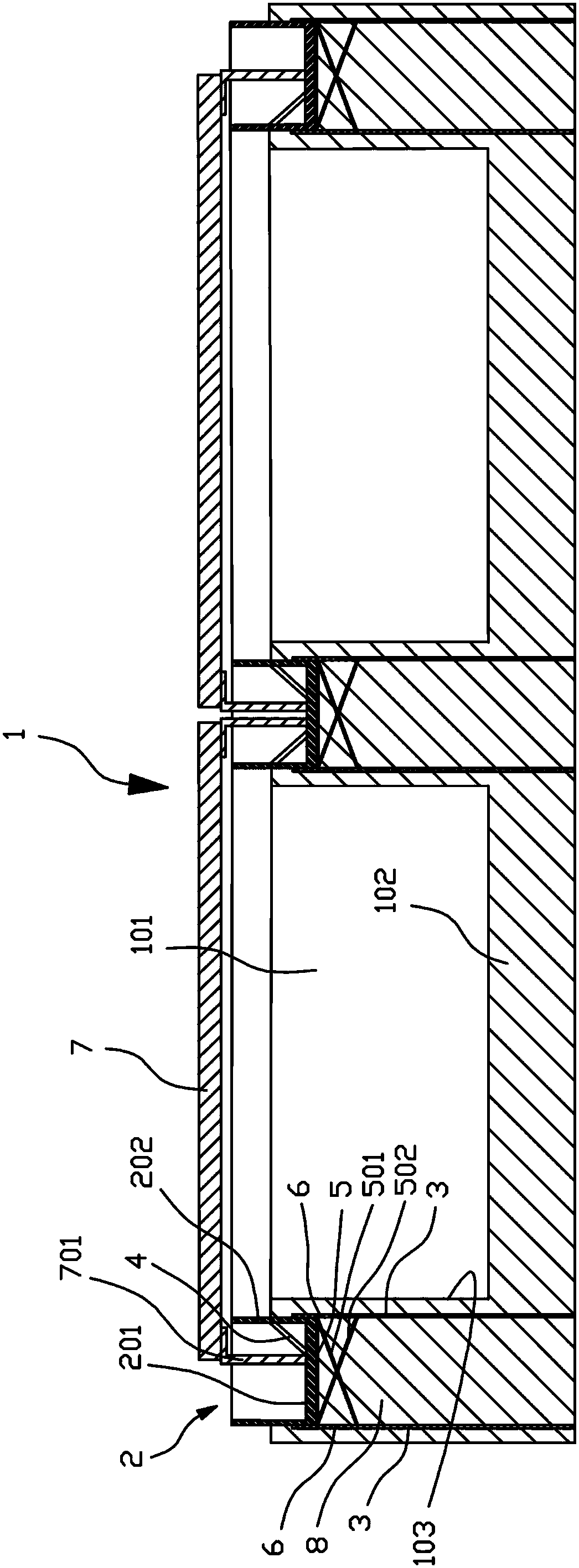

[0026] Depend on figure 1 , figure 2 , image 3 As shown, the concrete prefabricated pile steam curing pool of the present invention includes several rectangular pool bodies 101 with horizontal cross-sections arranged at intervals. Connected water seal groove 2, the adjacent side walls 103 of adjacent pool body 101 share a water seal groove 2, each pool body 101 is all provided with a rectangular pool cover 7 for covering the pool body 101, each The edge of each pool cover 7 is provided with a cover edge 701 extending downwards into the water seal groove 2, and the water seal groove 2 outside the top end of the four side walls of each pool body 101 is provided with a water seal groove for A guiding and positioning device for guiding and positioning the pool cover 7 during the process of hoisting the pool cover 7 on the pool body 101 .

[0027] The guide and positioning device refers to that at least one first guide and limit inclined block 4 is provided in the water seal g...

Embodiment 2

[0034] Depend on Figure 4 As shown, the water seal groove 2 is made of channel steel; the guide positioning device means that the cover edge 701 on the four sides of each pool cover 7 is provided with at least one second guide limit Inclined block 401, that is to say, at least one second guide and limit inclined block 401 is provided on the cover edge 701 on the upper side, lower side, left side, and right side of each pool cover 7 , usually, the number of the second guiding and limiting inclined blocks 401 on the cover edge 701 on the four sides of each pool cover 7 is equal, and each second guiding and limiting inclined blocks 401 are arranged symmetrically, that is to say, the upper The connection line of the corresponding second guide limit inclined block 401 on the side and the lower side is perpendicular to the upper side and the lower side, and the corresponding first wire limit inclined block 401 on the left side and the right side The connecting line is perpendicula...

Embodiment 3

[0038] Depend on Figure 5 As shown, the guide and positioning device refers to that the cover edge 701 on the four sides of each pool cover 7 is provided with at least one guide wheel 402 or bearing, that is to say, the upper surface of each pool body pool cover 7 At least one guide wheel 402 or bearing is provided on the cover edge 701 on the side, the lower side, the left side, and the right side. Usually, the guide wheels on the cover edge 701 on the four sides of each pool cover 7 The number of 402 or bearings is equal, and each guide wheel 402 or bearing is arranged symmetrically, that is to say the corresponding guide wheel 402 on the upper side and the lower side or the connecting line of the bearing and the upper side and the lower side vertical, the corresponding guide wheels 402 or bearings on the left side and the right side are perpendicular to the left side and the right side, and each guide wheel 402 or bearing can be mounted on the inner surface of the cover ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com