corn harvester header

A technology for corn harvesters and headers, which is applied to headers, harvesters, cutters, etc., can solve the problems of unreasonable overall structure layout, inability to adjust the angle of headers, and affect harvesting efficiency, so as to shorten the working distance and structure Compact and overall small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

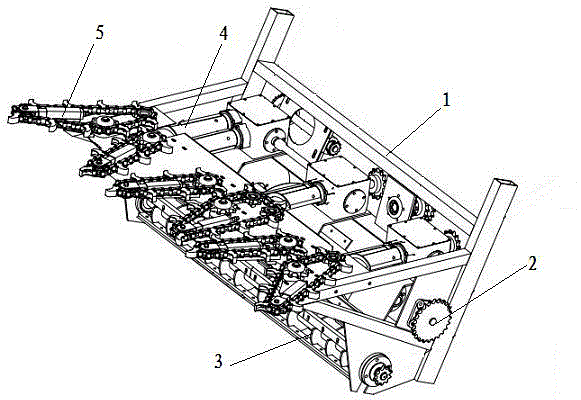

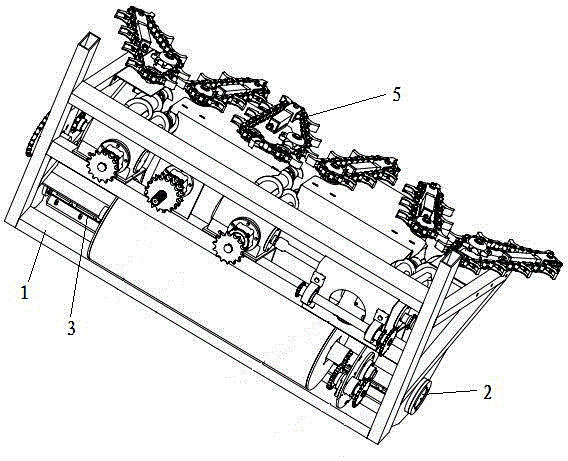

[0020] According to attached figure 1 and 2 It can be seen that the present invention specifically relates to a corn harvester header, and the overall specific structure of the header includes a header frame 1, a header auger 2, an ear picking device 4, a feeding device 5, and a suspension cutting device 3.

[0021] The main frame of the present invention is the header frame 1, and the header frame 1 plays the most important supporting role, and other devices on the header are all installed on the header frame. The unique structural design of the header frame 1 in the present invention arranges the header auger 2, ear picking device 4, feeding device 5, and hanging cutting device 3 on the header frame, making effective use of the working space of maximization.

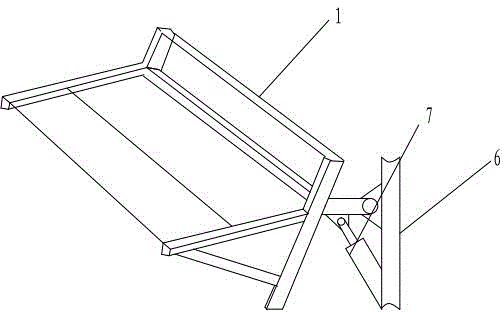

[0022] in the attached image 3 As can be seen in the figure, the fixed end of the header frame 1 is hinged with the car body 6, and a hydraulic cylinder 7 is provided at the hinge to drive. At the connection posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com