System for converting thermal energy to mechanical energy in a vehicle

A heat energy conversion and mechanical energy technology, applied in mechanical equipment, charging system, engine cooling, etc., can solve problems such as difficult to adjust air-cooled condensers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

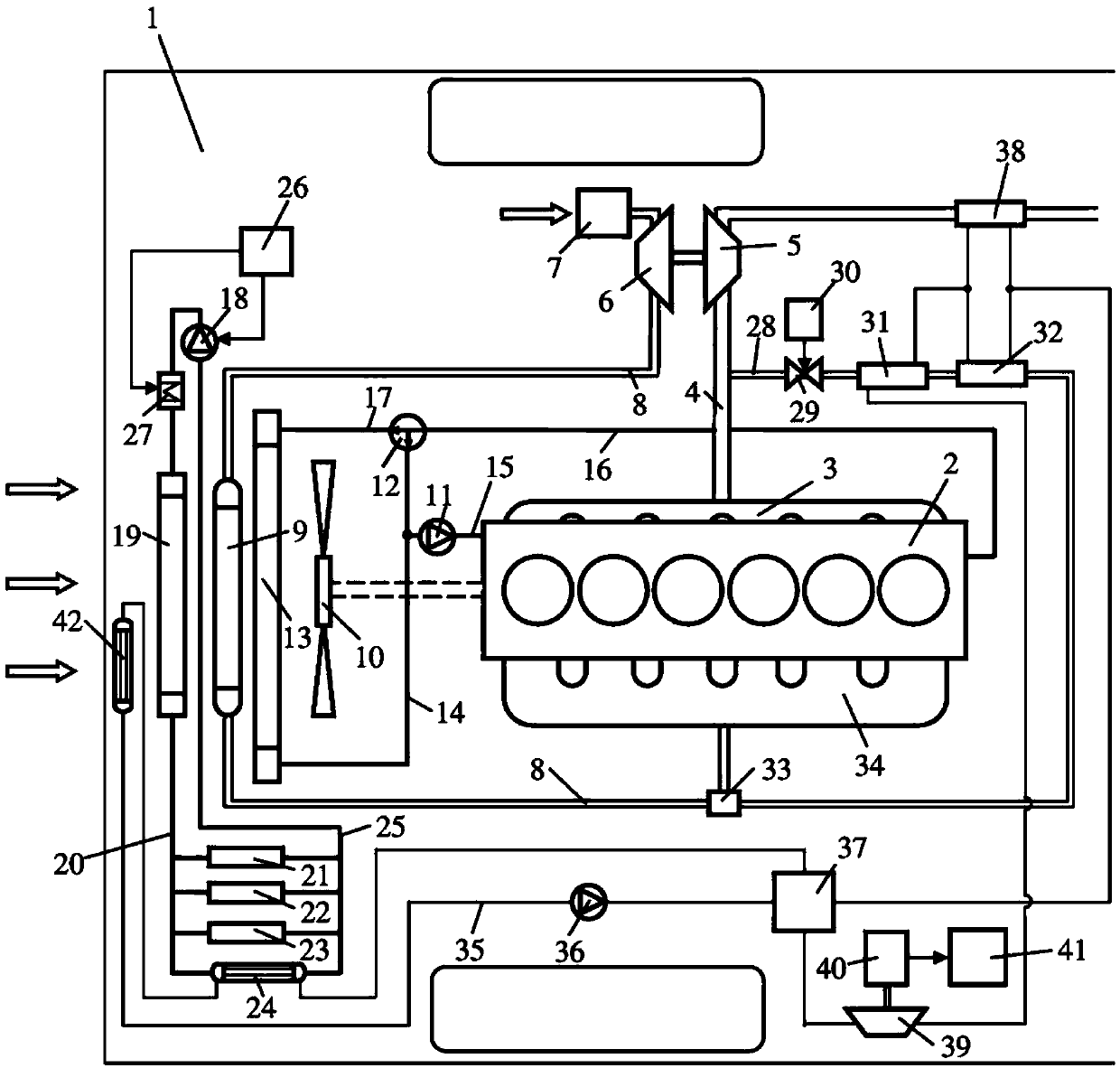

[0015] figure 1 A vehicle 1 powered by a supercharged internal combustion engine 2 is shown. The vehicle 1 may be a heavy duty vehicle powered by a supercharged diesel engine. Exhaust gases from cylinders of the engine 2 are led to an exhaust line 4 via an exhaust manifold 3 . The exhaust gas in the discharge line 4 which is to be at a pressure above atmospheric is led to the turbine 5 of the turbo unit. Thus, the turbine 5 is provided with a driving force which is transmitted to the compressor 6 via the connection. The compressor 6 then compresses the air which is led into the inlet line 8 via the filter 7 . A charge air cooler 9 is arranged in the supply line 8 . The charge air cooler 9 is positioned in the area at the front of the vehicle 1 . The purpose of the charge air cooler 9 is to cool the compressed air which is led to the engine 2 . The compressed air is cooled in the charge air cooler 9 by the air being pushed through the charge air cooler 9 by the airflow ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com