Stabilizer for SBS (styrene butadiene styrene) modified asphalt and preparation method thereof

A technology of modified asphalt and stabilizer, applied in building components, building insulation materials, buildings, etc., can solve problems such as unsatisfactory stabilization effect, lack of versatility, and cumbersome feeding process, and achieve good applicability, good effect, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

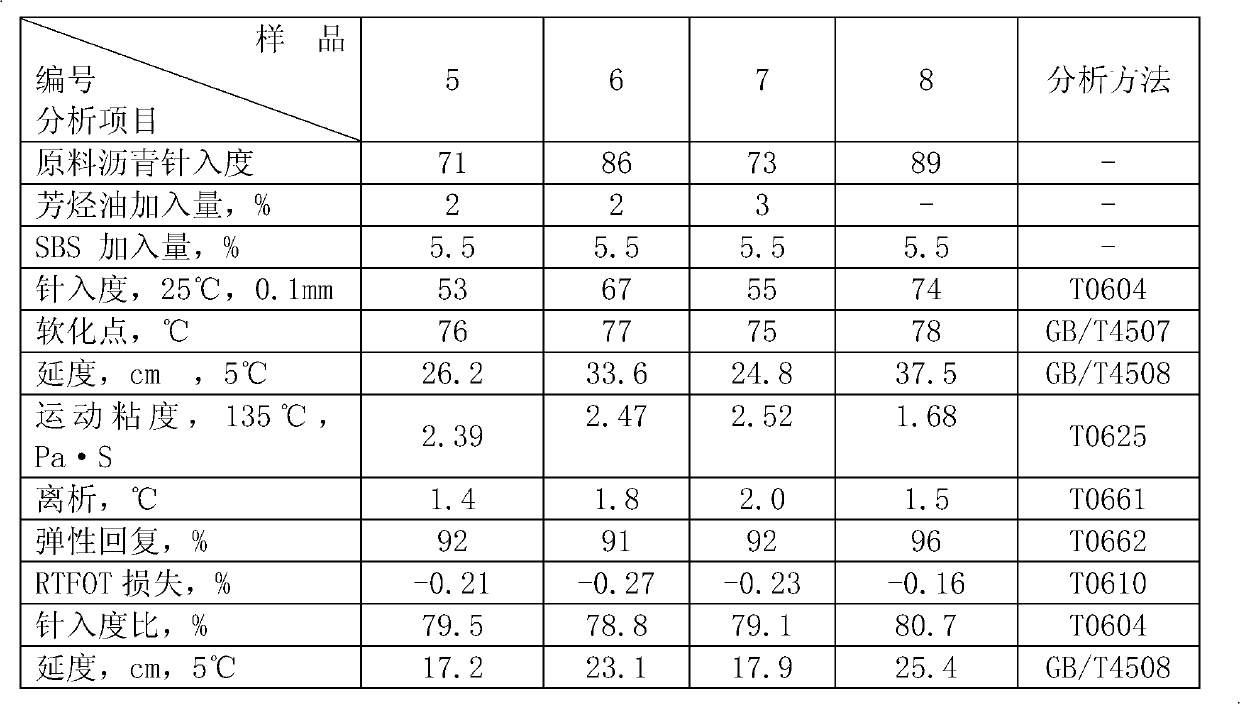

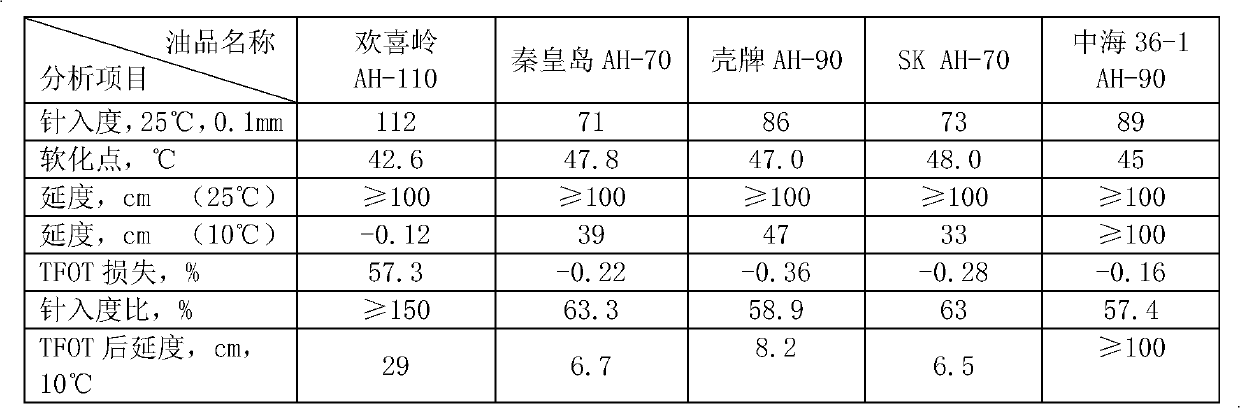

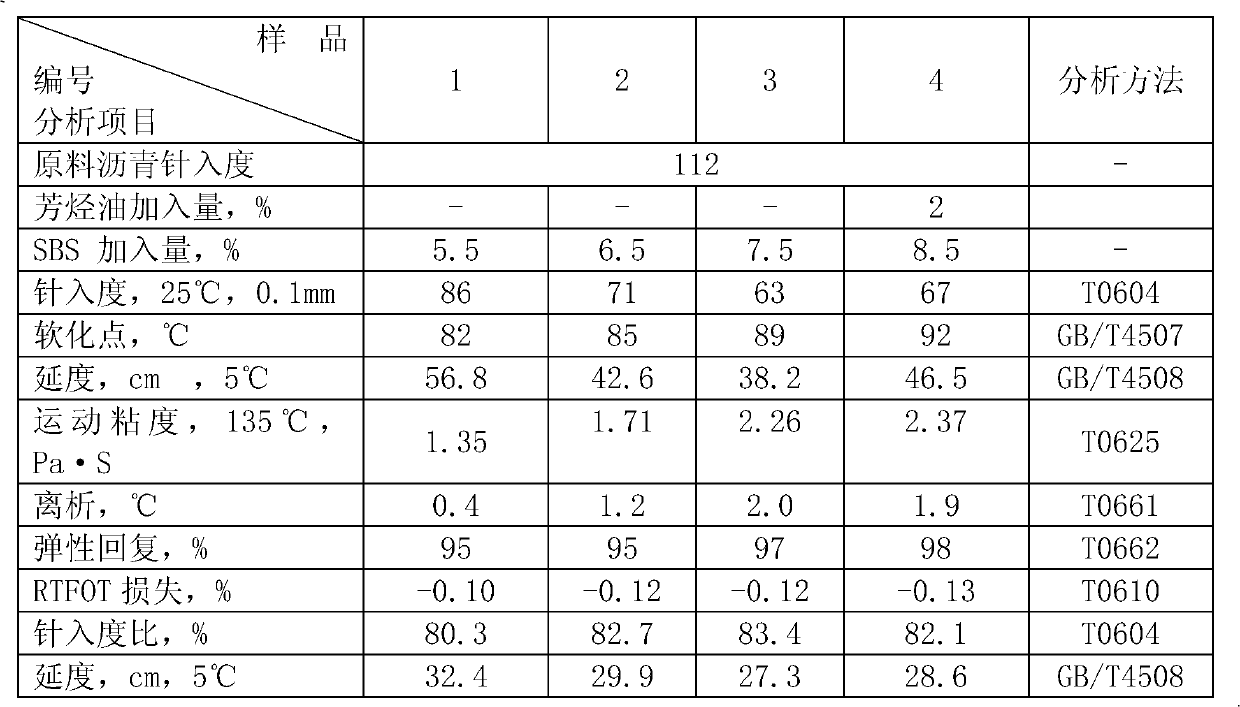

[0020] The raw asphalt is Huanxiling AH-110, with a penetration of 112. Take 1000 grams of sample, add 55 grams of SBS, and add 2.5 grams of stabilizer (including 0.75 grams of sulfur, 1.0 grams of aromatic oil, 0.5 grams of carbon black, and 0.25 grams of polystyrene) , shear at high speed with an emulsifying disperser for 40-60 minutes, and the reaction temperature is 170-185°C, and the asphalt sample obtained is No. 1. The performance analysis results are shown in Table 2, meeting the technical requirements of I-B in JTG F40-2004.

Embodiment 2

[0022] Raw asphalt is Huanxiling AH-110, with a penetration of 112. Take 1000 grams of sample, add 65 grams of SBS, and add 2.5 grams of stabilizer (including 0.75 grams of sulfur, 1.0 grams of aromatic oil, 0.5 grams of carbon black, and 0.25 grams of polystyrene) ,, High-speed shearing with emulsifying disperser for 40-60 minutes, the reaction temperature is 170-185 ° C, the asphalt sample obtained is No. 2. The performance analysis results are shown in Table 2, meeting the technical requirements of I-C in JTGF40-2004.

Embodiment 3

[0024] Raw asphalt is Huanxiling AH-110, with a penetration of 112. Take 1000 grams of sample, add 75 grams of SBS, and add 2.5 grams of stabilizer (including 0.75 grams of sulfur, 1.0 grams of aromatic oil, 0.5 grams of carbon black, and 0.25 grams of polystyrene) ,, High-speed shearing with emulsifying disperser for 40-60 minutes, the reaction temperature is 170-185 ° C, the asphalt sample obtained is No. 3. The performance analysis results are shown in Table 2, meeting the technical requirements of I-C in JTGF40-2004.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com