Method for sheet transfer and die cutting with gripper transport system

A conveying system and sheet technology, applied in the direction of sending objects, transportation and packaging, object supply, etc., to achieve the effect of precise orientation of sheets and high registration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

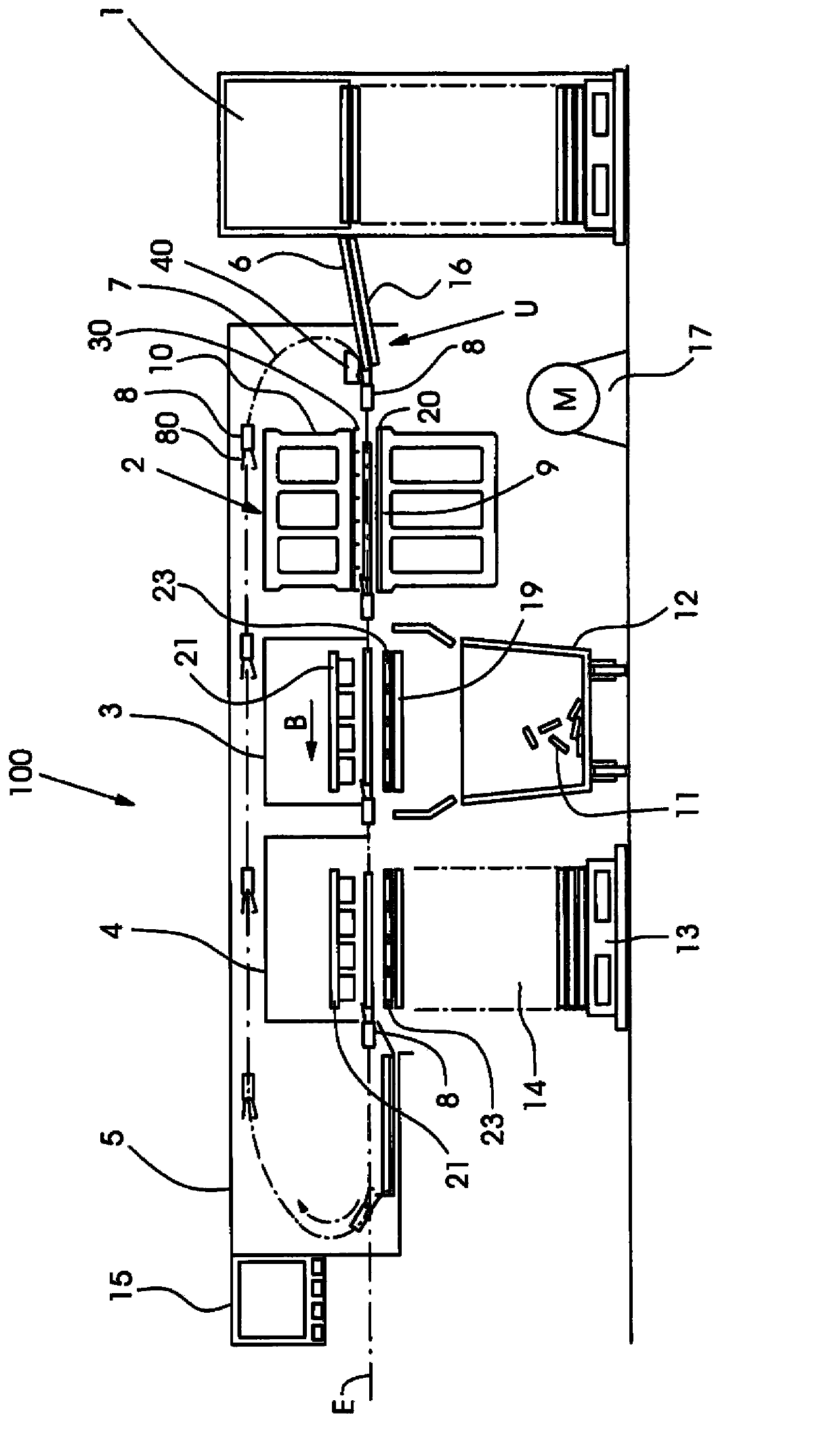

[0025] figure 1 The schematic design of a sheet die-cutting and embossing machine 100 for die-cutting, stripping, separating useful parts and depositing sheets made of paper, cardboard, plastics and the like is shown in FIG. The die-cutting and embossing machine 100 comprises a feeder 1, a die-cutting station 2, a stripping station 3 and a receiver 4 with a placement and useful part separation station 20, which consist of a common machine housing 5 carries and surrounds and is driven by the main driver 17. The processing stations 2 , 3 , 4 are accessible from one side, the so-called operator side; the drive train of the sheet-cutting and embossing machine 100 is located on the opposite side, the so-called drive side. A corresponding machine control device 15 controls the processes within the die-cutter 100 .

[0026] The sheets 6 are separated from a stack by means of a feeder 1 via so-called suction heads 18 , fed to the sheet conveyor system 7 at the sheet transfer point U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com