Method for transferring sheets and die-cutting machine with gripper-conveying system

A conveying system, sheet technology, applied in the directions of transportation and packaging, object supply, pile separation, etc., to achieve the effect of precise orientation of sheets and high registration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] figure 1 The schematic design of a sheet die-cutting and embossing machine 100 for die-cutting, stripping, separating useful parts and depositing sheets made of paper, cardboard, plastics and the like is shown in FIG. The die-cutting and embossing machine 100 comprises a feeder 1, a die-cutting station 2, a stripping station 3 and a receiver 4 with a placement and useful part separation station 20, which consist of a common machine housing 5 carries and surrounds and is driven by the main driver 17. The processing stations 2 , 3 , 4 are accessible from one side, the so-called operator side; the drive train of the sheet-cutting and embossing machine 100 is located on the opposite side, the so-called drive side. A corresponding machine control device 15 controls the processes within the die-cutter 100 .

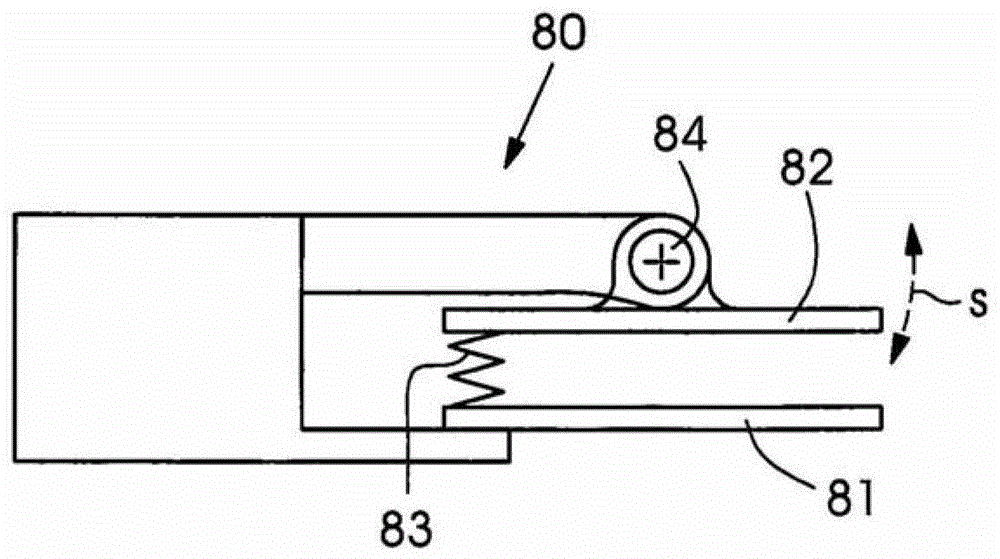

[0026] The sheets 6 are separated from a stack by means of a feeder 1 via so-called suction heads 18 , fed to the sheet conveyor system 7 at the sheet transfer point U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com