Connecting pipe assembly equipment and connecting pipe assembly method

A technology for assembling equipment and connecting pipes, which is applied in the field of automatic production of air-conditioning and air-conditioning connecting pipes. It can solve problems such as high labor intensity, safety issues of people and objects, and employees are prone to fatigue and dullness, so as to ensure production quality and meet consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in detail below with reference to the accompanying drawings and examples.

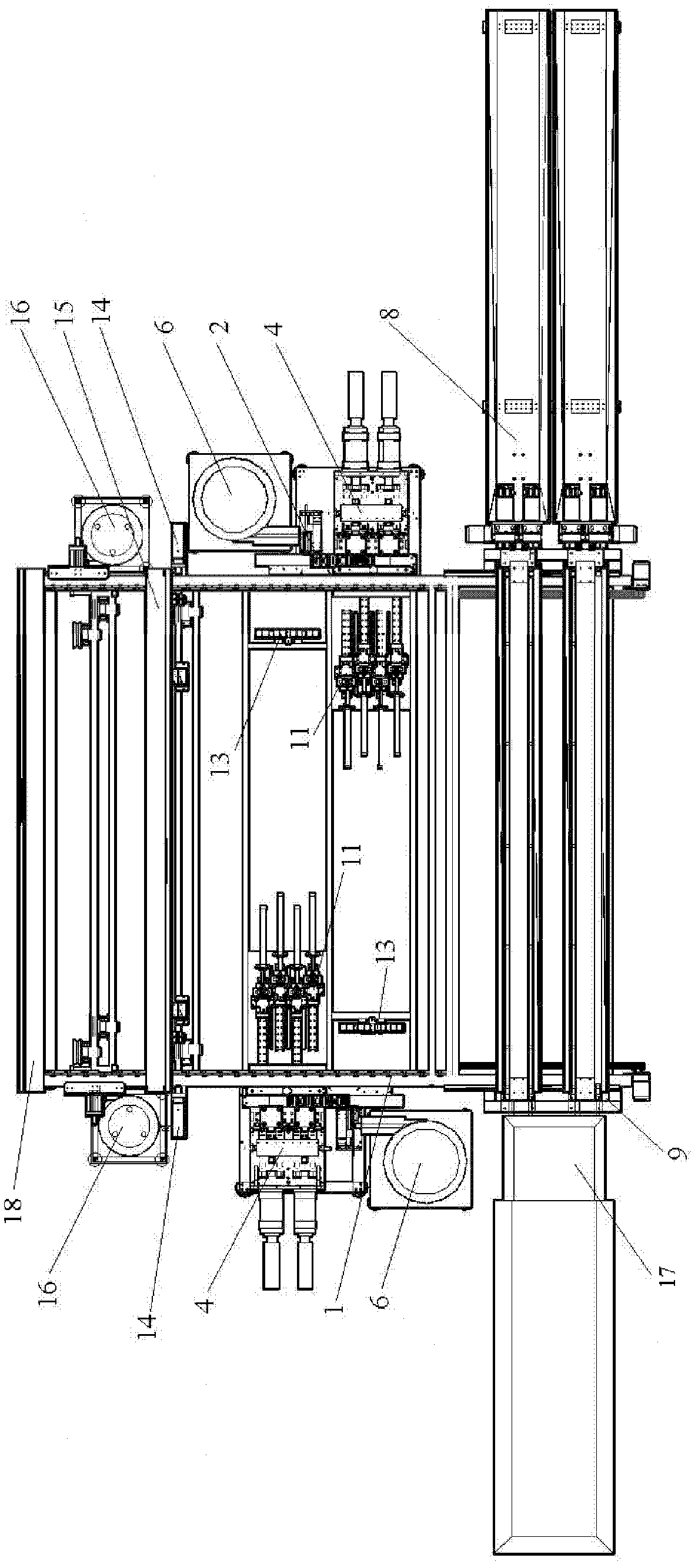

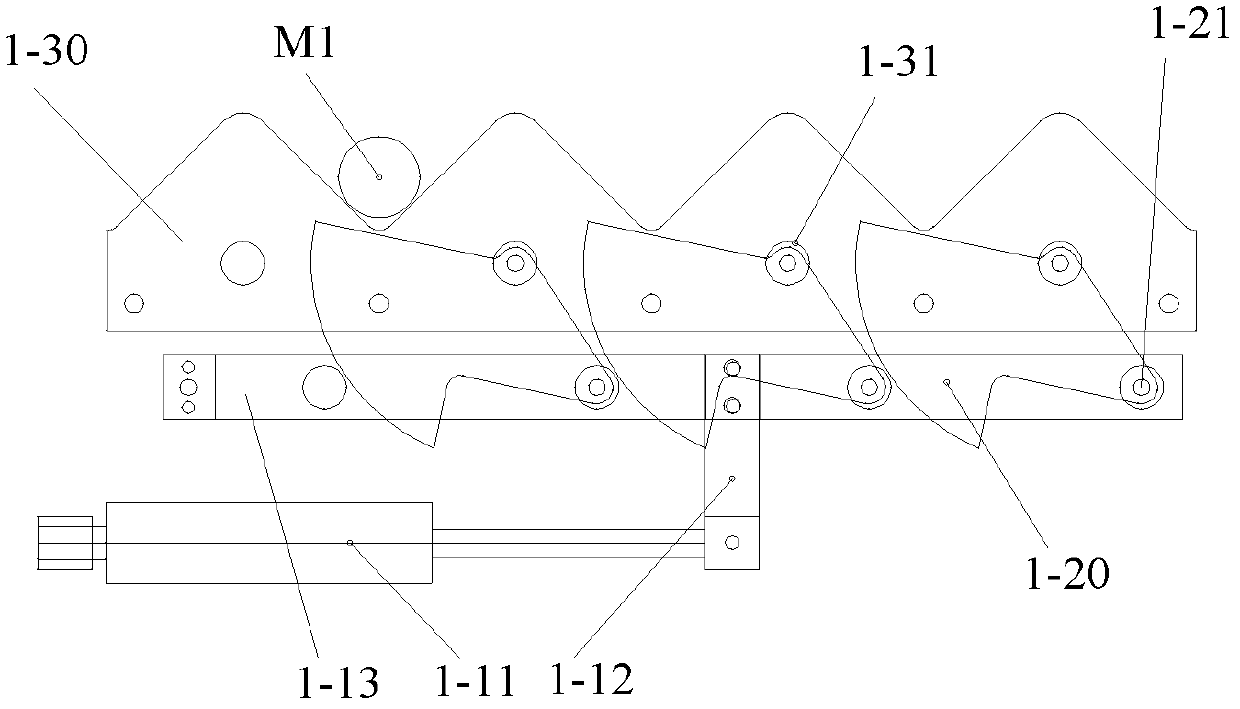

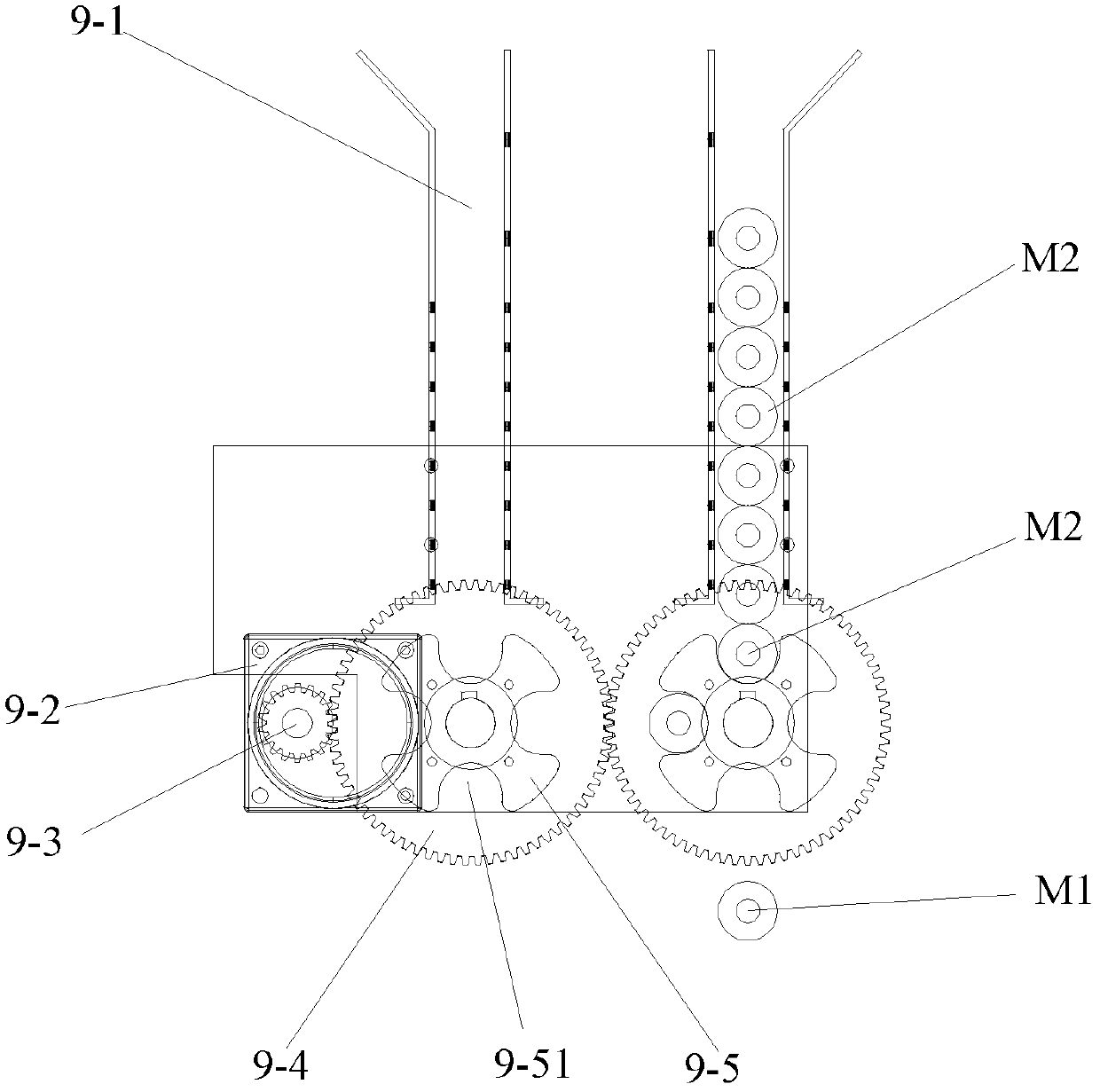

[0072] A connecting pipe assembly arrangement according to the present invention includes: a conveying device 1 for conveying the connecting pipe M1, wherein the connecting pipe M1 includes a material pipe and a cotton tube sleeved on the outside of the material pipe; the pipe threading device 9 is arranged on The top of the conveying device 1 is used to make the material tube pass through the cotton tube; the tube feeding device 17 is arranged on the side of the tube passing device 9 along the extension direction of the connecting pipe M1, and is used to transmit the material tube; the cotton tube feeding device 8 , arranged on the other side of the pipe threading device 9 along the extending direction of the connecting pipe M1, for conveying the cotton pipe.

[0073] The cotton tube feeding device 8 sends the cotton tube to the tube threading device 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com