Homogenizing mixer

A mixer and homogenization technology, applied in mixers, mixing methods, mixers with rotary stirring devices, etc., can solve problems such as overloading, complicated construction facilities for operating agitators and driving units, and reduce failures. factors, cost savings, the effect of streamlining the stirring unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

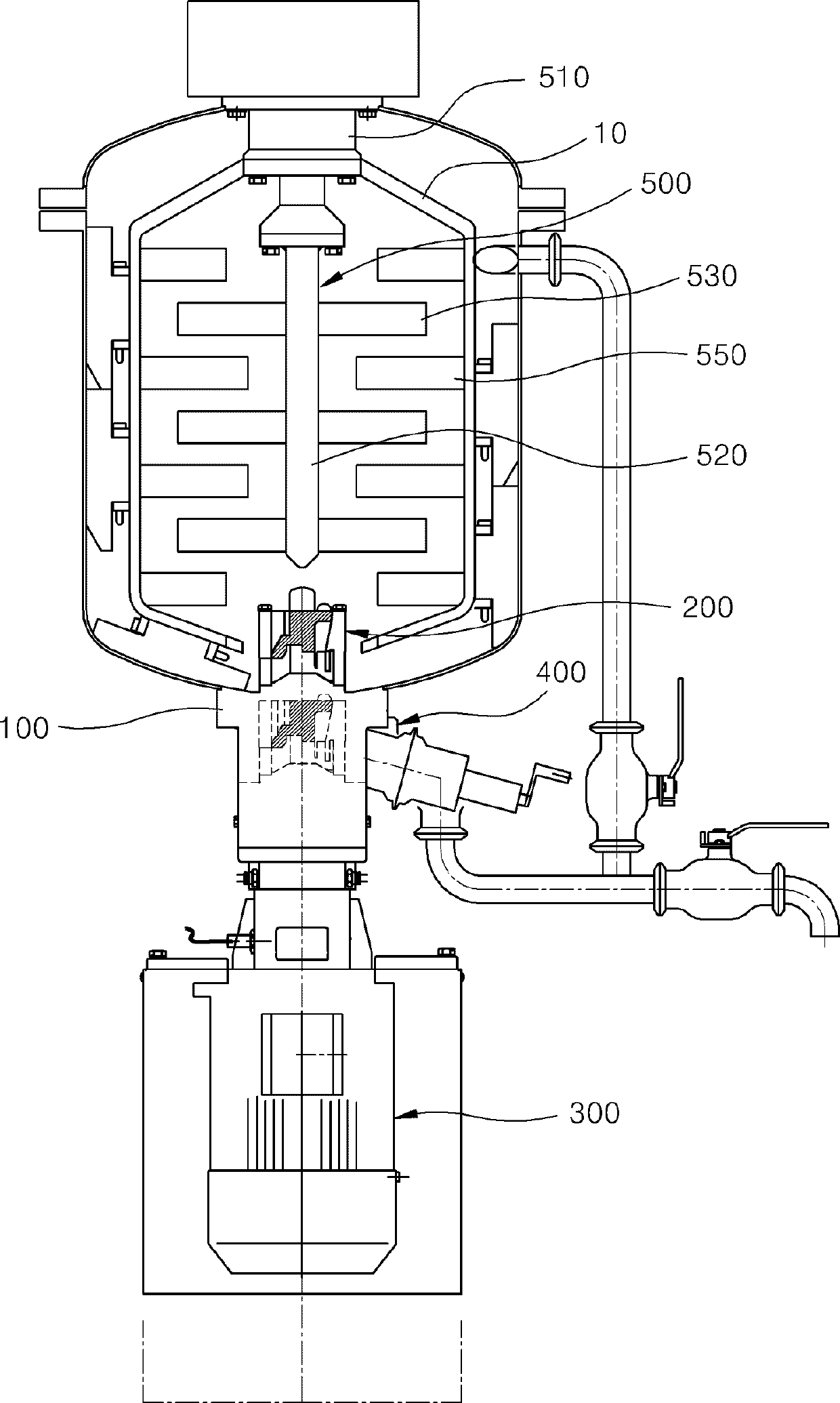

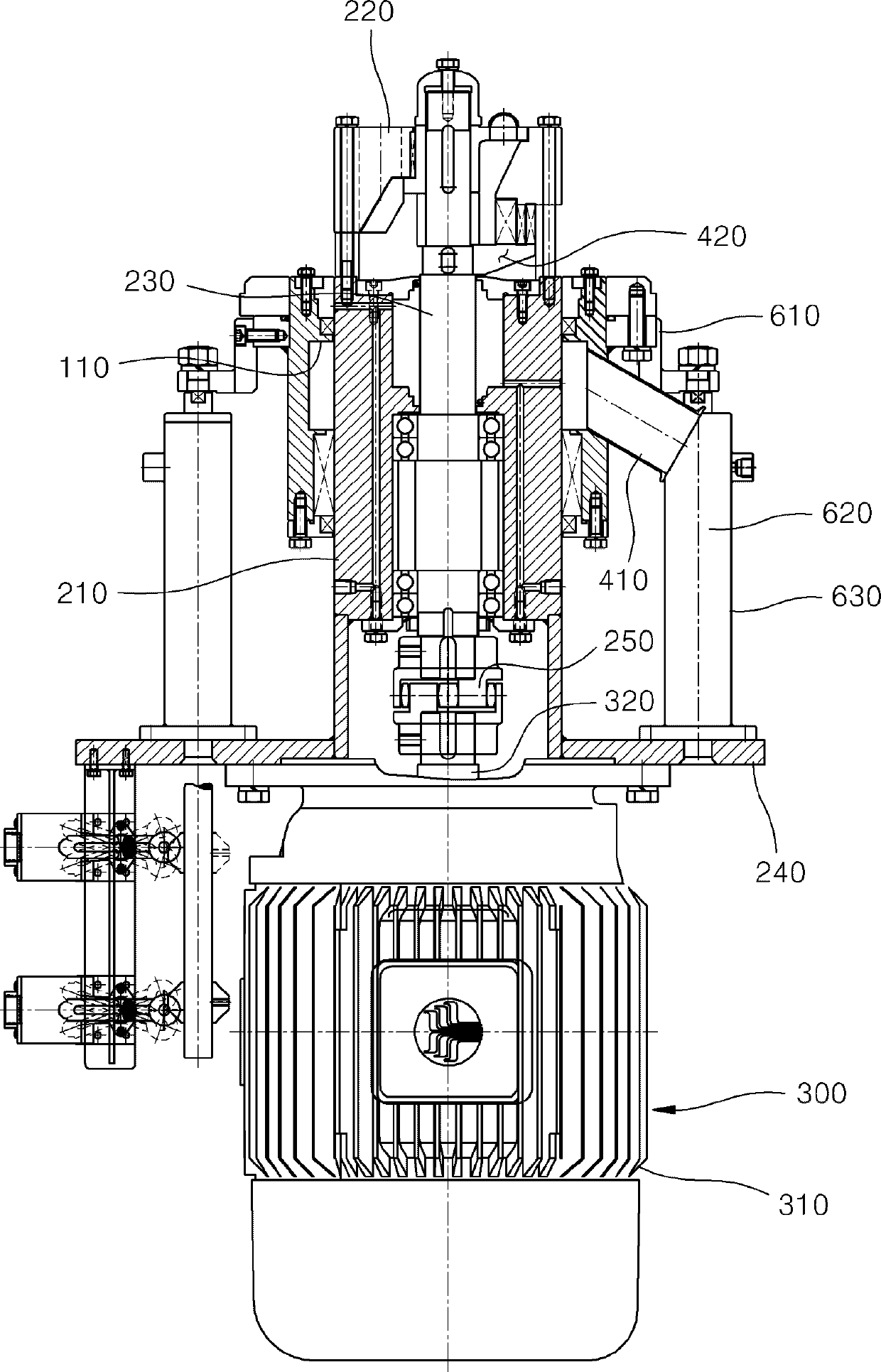

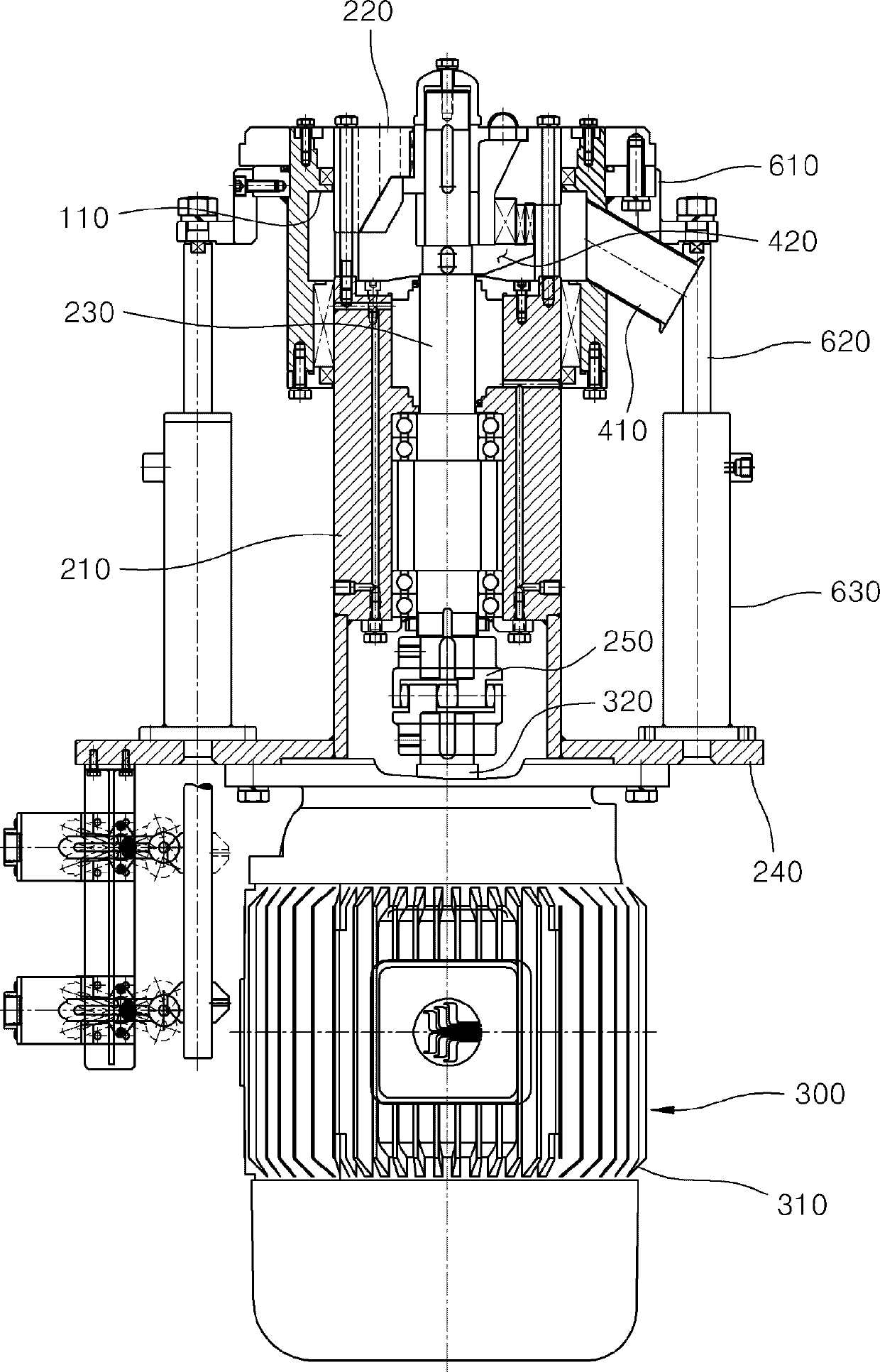

[0024] Reference will be made to the accompanying drawings ( Figure 1 to Figure 6 ) describes a homomixer according to a preferred embodiment of the present invention.

[0025] refer to Figure 1 to Figure 6 , according to the preferred embodiment of the present invention, the homogeneous mixer includes: a container 10, which has an inner space to accommodate materials with different properties; a fixing frame 100, which is arranged to be fixed on the bottom of the container 10, and Stirring unit 200, the stirring unit is arranged in the fixed frame 100, so as to be lifted and lowered by the lifting unit, and the stirring unit stirs the material contained in the container 10; the driving unit 300, the driving unit is arranged in the stirring unit 200 to transmit the rotational driving force for the agitation unit 200; and a discharge unit 400 which is agitated by the agitation unit 200 and discharges the homogenized material to the outside of the mixer.

[0026] In more det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com