Glue stick based on starch mixed ethers

A starch and glue stick technology, applied in the direction of glue sticks, starch-derived adhesives, adhesives, etc., to achieve the effects of outstanding adhesion and storage performance, uniform rubbing, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

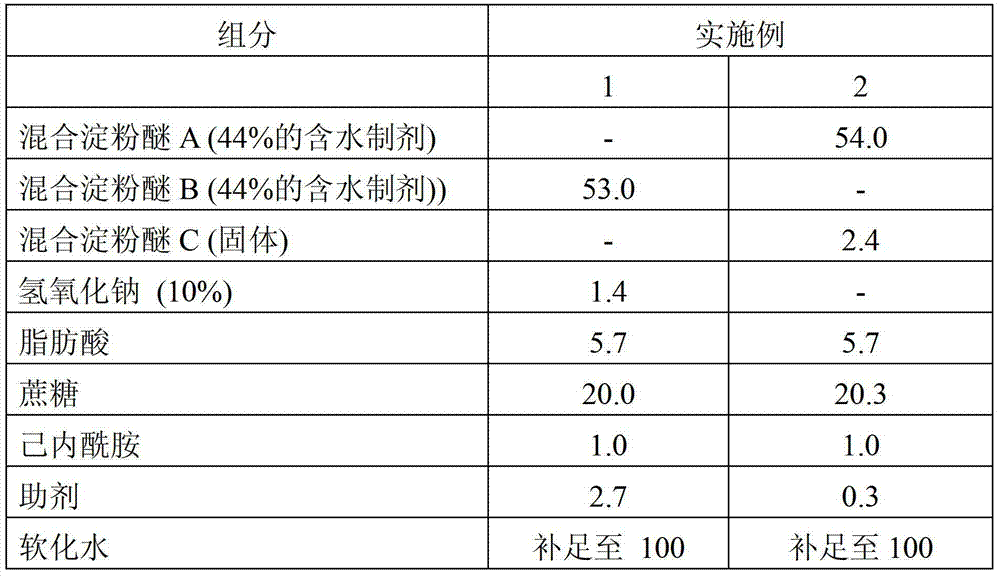

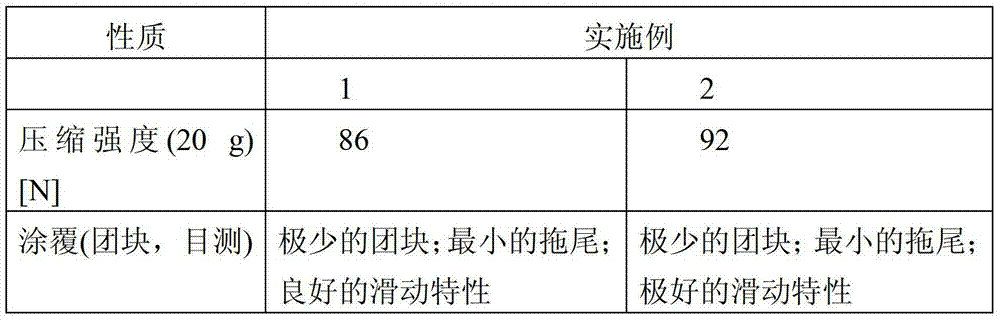

[0062] I. raw material

[0063] - Mixed starch ether A: hydroxypropyl carboxymethyl starch based on potato starch; molar ratio of hydroxypropyl to carboxymethyl > 1; , Its viscosity is about 70,000mPas when measured under the condition of 20rpm;

[0064] - mixed starch ether B: hydroxypropyl carboxymethyl starch based on a mixture of potato starch and tapioca starch; the molar ratio of hydroxypropyl to carboxymethyl > 1; The viscosity of the aqueous solution is about 80,000 mPas when measured under the conditions of 20°C, rotor 7, and 20 rpm;

[0065] - Mixed starch ether C: hydroxypropyl carboxymethyl starch based on potato starch; molar ratio of hydroxypropyl to carboxymethyl <1; Or its viscosity is about 5,000mPas when measured under the condition of 5, 20rpm;

[0066] - Fatty acids: commercially available fatty acids having 14 to 18 carbon atoms.

[0067] II. Manufacturing of glue sticks

[0068] The components of Table I were mixed at 80°C and processed into glue s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com