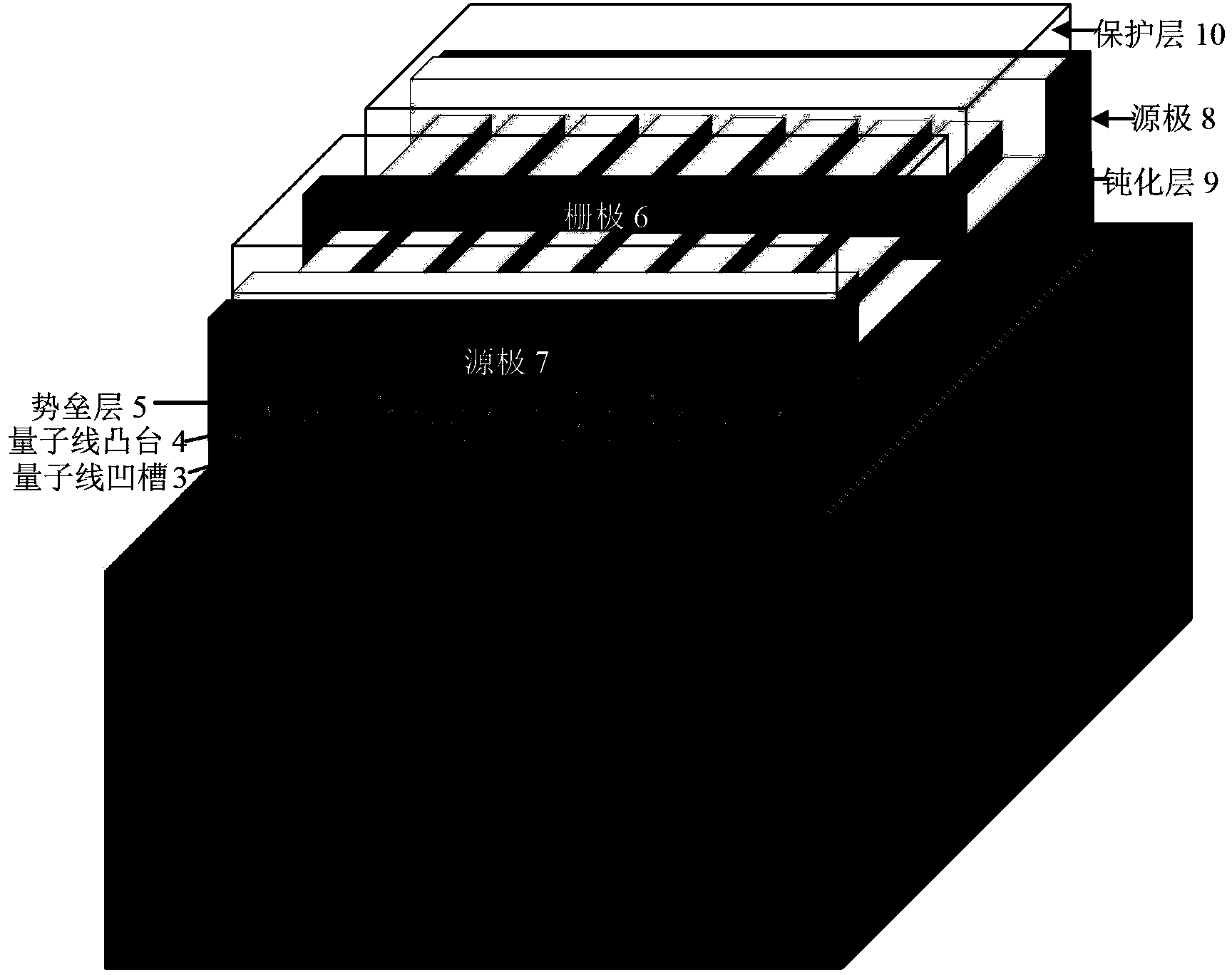

Secondary-growth one-dimensional electron gas GaN-based HEMT (High Electron Mobility Transistor) device and preparation method

A secondary growth and electron gas technology, applied in the field of microelectronics, can solve the problems of small breakdown electric field, electron concentration limitation, poor electron transport characteristics, etc., and achieve the goal of improving high temperature and high pressure characteristics, improving power characteristics, and improving uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

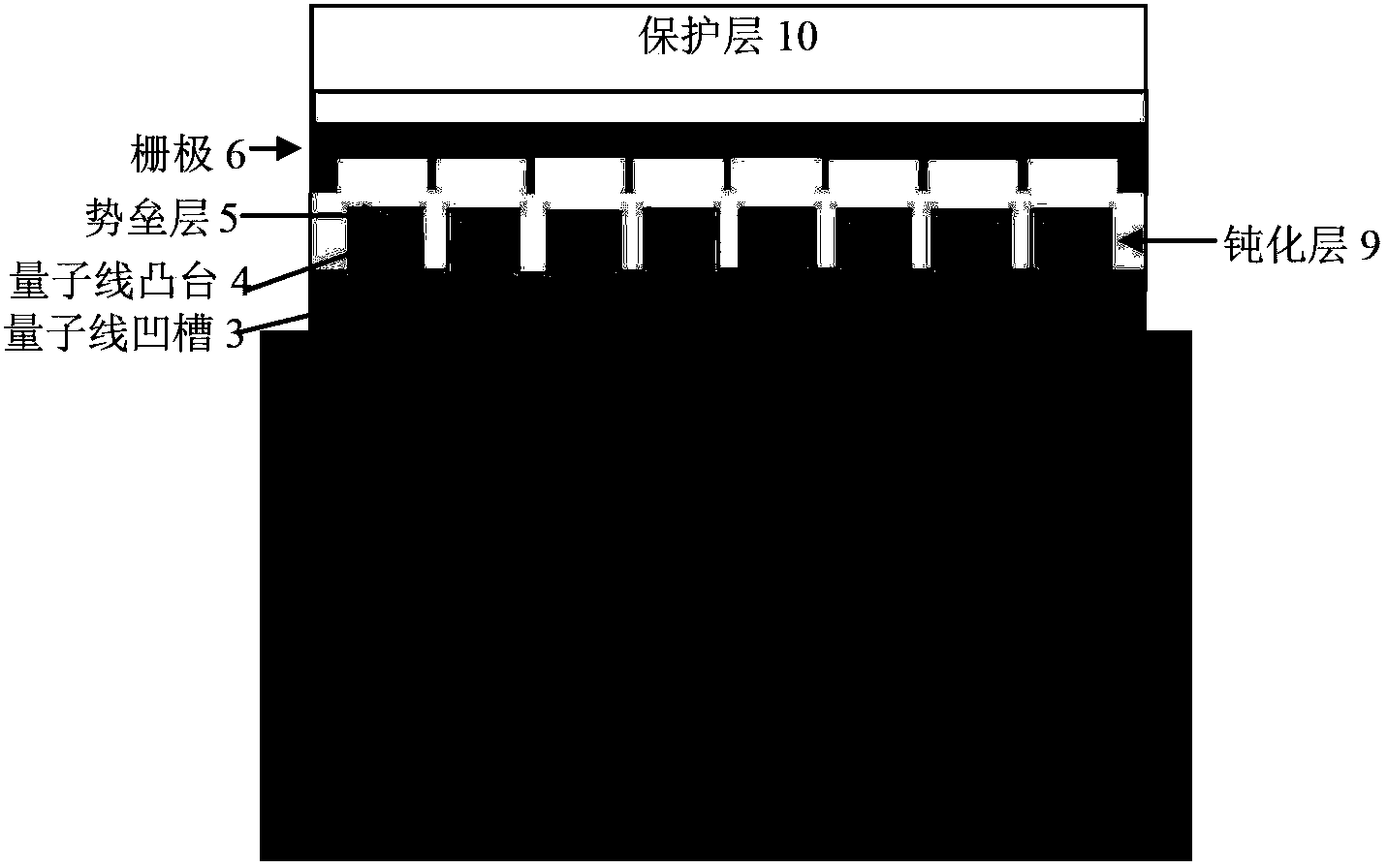

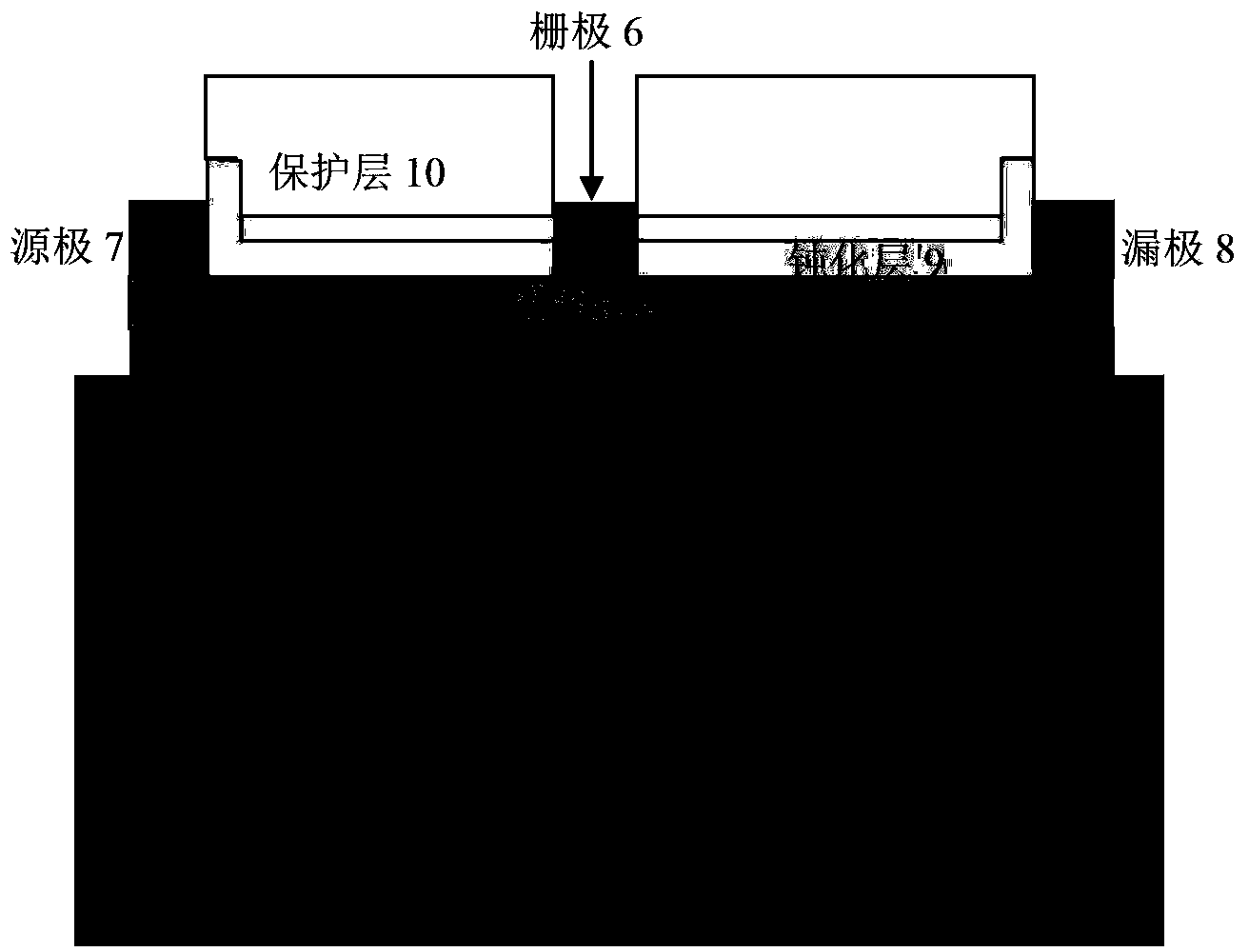

[0056] Embodiment 1, the production substrate 1 is sapphire, the buffer layer 2 is GaN, the barrier layer 5 is AlGaN, the passivation layer 9 is SiN, the protective layer 10 is SiN, the depth of the quantum wire groove 3 is 20nm, and the width is 10nm. The width of the quantum wire boss 4 is 10 nm, and the quantum wire groove 3 and the quantum wire boss 4 are periodically arranged one-dimensional electron gas GaN-based HEMTs.

[0057] Step 1, using metal organic chemical vapor deposition technology MOCVD to epitaxially GaN semiconductor material with a thickness of 1 μm on the sapphire substrate 1 as the buffer layer 2; the process conditions for the epitaxial GaN buffer layer 2 are: the temperature is 1020 ° C, and the pressure is 200 Torr , the hydrogen flow rate is 4600 sccm, the ammonia gas flow rate is 4600 sccm, and the gallium source flow rate is 200 μmol / min.

[0058] Step 2, coating electron photoresist on the buffer layer 2, using electron beam lithography to etch ou...

Embodiment 2

[0075] Embodiment 2, the production substrate 1 is silicon carbide, the buffer layer 2 is GaN, the barrier layer 5 is AlGaN, the passivation layer 9 is SiN, and the protective layer 10 is SiO 2 , the depth of the quantum wire groove 3 is 40nm, the width is 50nm, the width of the quantum wire boss 4 is 50nm, and the quantum wire groove 3 and the quantum wire boss 4 are one-dimensional electron gas GaN-based HEMTs arranged periodically.

[0076] Step 1, epitaxially epitaxially GaN buffer layer 2 with a thickness of 3 μm on silicon carbide substrate 1 .

[0077] Using metal organic chemical vapor deposition MOCVD equipment under the process conditions of temperature 1020 ° C, pressure 200 Torr, hydrogen flow rate 5000 sccm, ammonia gas flow rate 5000 sccm, gallium source flow rate 220 μmol / min, epitaxy on silicon carbide substrate 1 GaN buffer layer 2 with a thickness of 3 μm.

[0078] Step 2: Photoetch the required quantum wire pattern on the buffer layer 2, and etch a pluralit...

Embodiment 3

[0102] Embodiment 3, the production substrate 1 is silicon, the buffer layer 2 is GaN, the barrier layer 5 is AlGaN, and the passivation layer 9 is SiO 2 , the protective layer 10 is SiN, the depth of the quantum wire groove 3 is 70nm, the width is 100nm, the width of the quantum wire boss 4 is 100nm, and the quantum wire groove 3 and the quantum wire boss 4 are one-dimensional electron gas arranged periodically GaN-based HEMTs.

[0103] In step A, a GaN buffer layer 2 with a thickness of 5 μm is epitaxially formed on the silicon substrate 1 .

[0104] A GaN buffer layer 2 with a thickness of 5 μm was epitaxially grown on a silicon substrate 1 using metal-organic chemical vapor deposition MOCVD equipment; The gas flow rate is 5200 sccm, and the gallium source flow rate is 240 μmol / min.

[0105] In step B, the required quantum wire pattern is photoetched on the buffer layer 2, and several quantum wire grooves 3 spaced apart from each other are etched on the buffer layer 2 to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Epitaxial thickness | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com