Wind-resistant composite insulator

A technology of composite insulators and sheds, which is applied in the direction of suspension/strain insulators, etc., can solve the problems of reducing the effective creepage distance of the product, the force of the sheds, and the wear of the sheds, so as to achieve a good external insulation structure, improve product life, and improve product quality. Long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

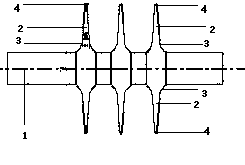

[0019] The invention provides an arrangement structure of equal-diameter sheds for wind-resistant composite insulators. The sheds 2 are arranged on the periphery of the rod body 1, and the cross section of the sheds 2 is connected to the rod body 1 from the root of the shed 3 to the top 4 of the shed, which is composed of a gradient structure from large to small, which is suitable for the wind load. , to fully reduce the bending deformation of the shed 2. The diameter of the sheds is 85mm, and the distance between the tops of two adjacent sheds is 58mm.

[0020] Attached below figure 2 The arrangement structure of shed sheds with large and small diameters for a wind-resistant composite insulator of the present invention will be further described.

Embodiment 2

[0022] The invention discloses a shed shed arrangement structure of large and small diameters for a wind-resistant composite insulator, which is composed of a rod body 1 and a shed 2. The shed 2 is designed to be open, and the strength of the root 3 of the shed is improved. The sheds 2 are arranged on the periphery of the rod body 1, and the cross section of the sheds 2 is connected to the rod body 1 from the root of the shed 3 to the top 4 of the shed, which is composed of a gradient structure from large to small, which is suitable for the wind load. , to fully reduce the bending deformation of the shed 2. The diameter of the large shed is 200 mm, the diameter of the small shed is 170 mm, and the distance between the tops of two adjacent sheds is 43 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com