Digital cam continuous zooming system

A zoom system and cam technology, applied in optical elements, optics, instruments, etc., can solve the problems of difficult machining, increased cost, poor accuracy, etc., and achieve the effects of easy assurance of assembly accuracy, convenient adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

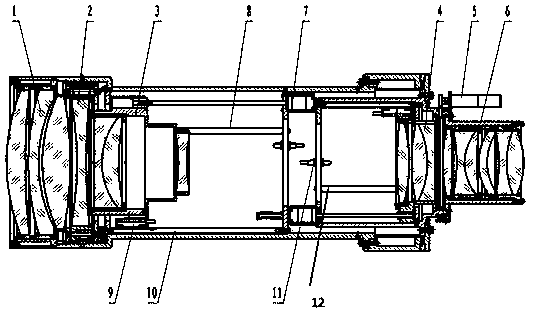

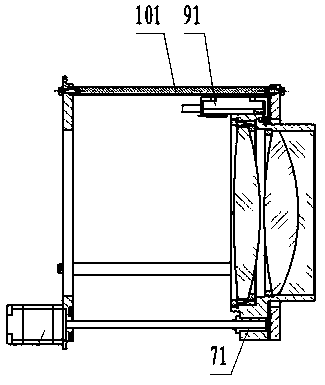

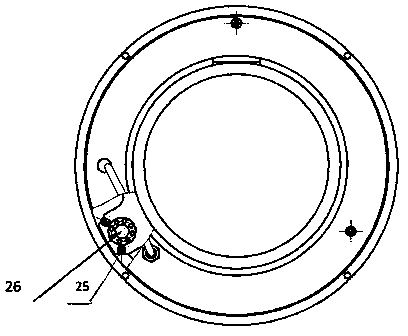

[0031] see Figure 1-8 ,

[0032] Linear drives require the following key components: linear motors, linear guides, and linear displacement sensors. Linear motors can directly convert electrical energy into linear motion mechanical energy without the need for an intermediate conversion structure transmission system, which has obvious advantages over traditional methods, such as simple structure, fast speed, and high precision.

[0033] In the scheme, the digital cam technology (motor program control) is used to replace the mechanical cam to realize the continuous zoom control method of the zoom optical lens. Use the computer to control the drive motor according to the zoom equation, so that each moving mirror group in the zoom lens can obtain the required linear or nonlinear precise displacement, ensure the stability of the image plane, obtain satisfactory imaging results, and output accurate focal length values at the same time. To meet the needs of equipment for measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com