Multifunctional explosion-proof ball

An explosion-proof ball, multi-functional technology, applied in blasting and other directions, can solve the problems of ball cover inertial out of control, no protection, social panic, etc., to achieve the effect of improving blast resistance and sealing ability, reducing the probability of injury, and quick and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the specific implementation process of multi-functional anti-virus and explosion-proof equipment and vacuum weak explosion, pre-tightened winding wire anti-explosion and signal blocking methods for security equipment, there can be many combinations to choose from.

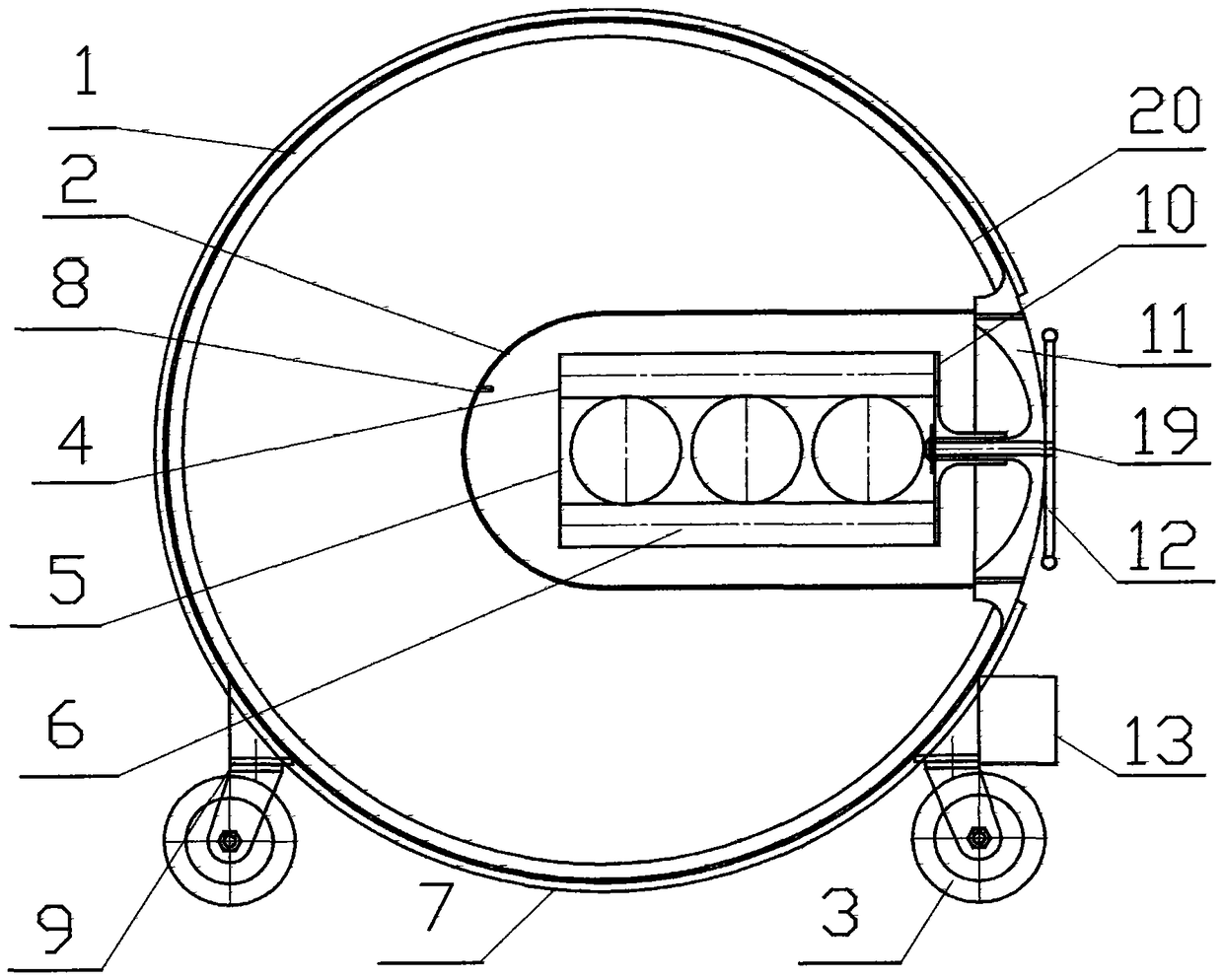

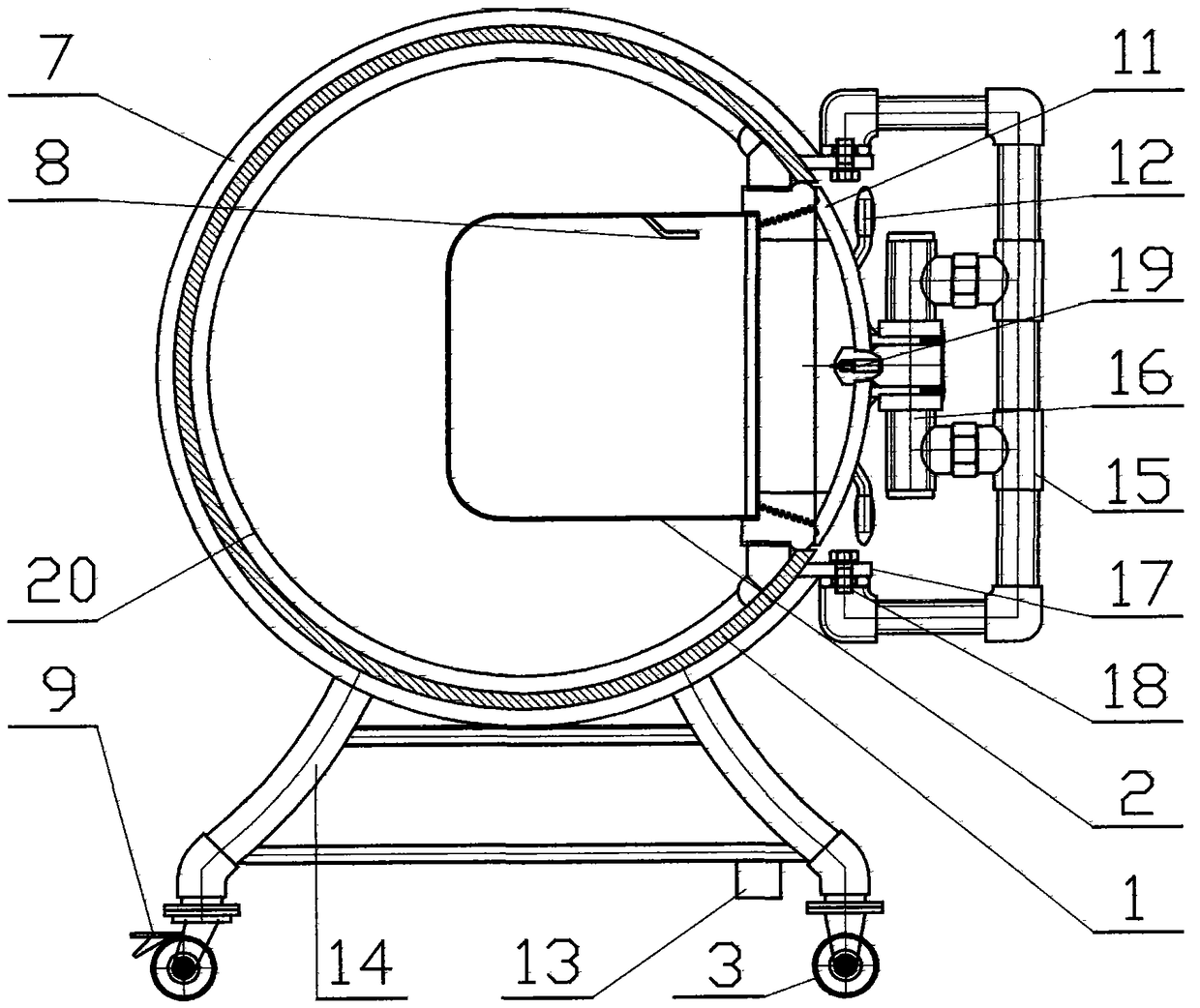

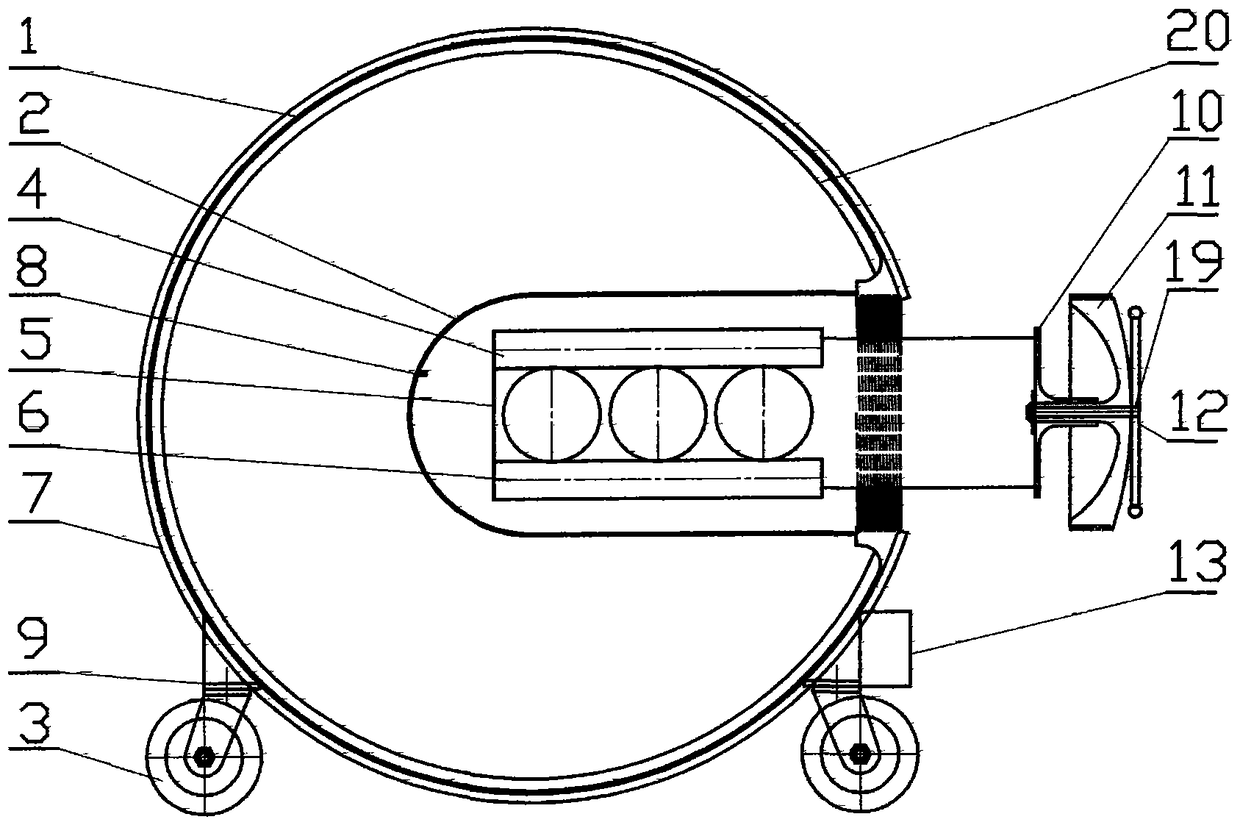

[0030] Multifunctional anti-virus and explosion-proof equipment, consisting of protective shell (1), vacuum liner (2), wheels (3), slide rail (4), slide rail mounting plate (5), anti-explosion net pocket (6), pre-tightened winding wire layer (7), vacuum isolation plug pad (8), wheel stopper (9), slide rail connecting plate (10), protective cover (11), cover unlocking handle (12), electronic signal blocker (13 ) trailer frame (14), large crank arm (15), small crank arm (16), pivot frame (17), pivot shaft (18), pressure relief valve (19), anti-radiation lead layer (20) and other components (see figure 1 , figure 2 ).

[0031] Among the components of each part, the protective shell (1) and the protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com