Slight-contact type sealed bearing

A sealed bearing and light contact technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of affecting the contact state between the lip of the sealing ring and the sealing groove, reducing the service life of the bearing, and the large starting torque of the bearing, etc., to achieve Prevent the intrusion of external dust or other pollutants, improve the service life and reliability, and have a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

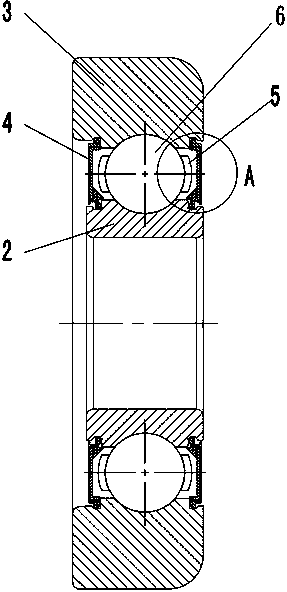

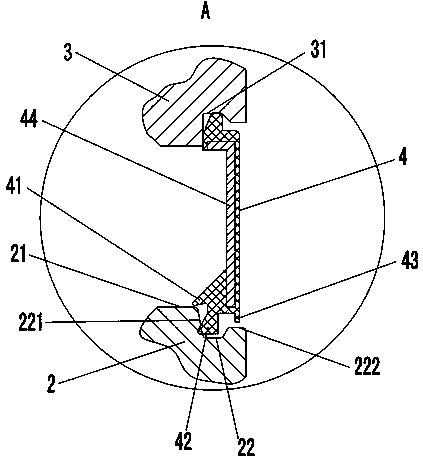

[0016] Take the gap between the grease-returning lip ring 41 of the sealing ring 4 and the outer circle 21 of the inner ring rib of the bearing inner ring 2 as 0.5mm, and the constant contact lip ring 42 of the sealing ring 4 and the inner ring sealing groove of the bearing inner ring 2 The interference of the end face 221 is 0.5mm, and the gap between the dustproof lip ring 43 of the sealing ring 4 and the notch 222 of the inner ring seal groove of the bearing inner ring 2 is 0.5mm; when the inner and outer rings of the bearing are deflected , the interference fit between the grease-returning lip ring 41 and the outer circle 21 of the inner ring rib is 0.2mm, and the interference fit between the regular contact lip ring 42 and the end face 221 of the sealing groove of the inner ring is 0.2mm.

Embodiment 2

[0018] Take the gap between the grease-returning lip ring 41 of the sealing ring 4 and the outer circle 21 of the inner ring rib of the bearing inner ring 2 as 0.1mm, and the constant contact lip ring 42 of the sealing ring 4 and the inner ring sealing groove of the bearing inner ring 2 The interference of the end face 221 of the bearing is 0.1mm, and the gap between the dustproof lip ring 43 of the sealing ring 4 and the notch 222 of the inner ring seal groove of the bearing inner ring 2 is 0.1mm; when the inner and outer rings of the bearing are deflected , the interference fit between the grease-returning lip ring 41 and the outer circle 21 of the inner ring rib is 0.4 mm, and the interference fit between the regular contact lip ring 42 and the end face 221 of the inner ring sealing groove is 0.01 mm.

Embodiment 3

[0020] Take the gap between the grease-returning lip ring 41 of the sealing ring 4 and the outer circle 21 of the inner ring rib of the bearing inner ring 2 as 0.3mm, and the constant contact lip ring 42 of the sealing ring 4 and the inner ring sealing groove of the bearing inner ring 2 The interference of the end face 221 of the bearing is 0.3mm, and the gap between the dustproof lip ring 43 of the sealing ring 4 and the notch 222 of the inner ring seal groove of the bearing inner ring 2 is 0.3mm; when the inner and outer rings of the bearing are deflected , the interference fit between the grease-returning lip ring 41 and the outer circle 21 of the inner ring rib is 0.3 mm, and the interference fit between the regular contact lip ring 42 and the end face 221 of the inner ring sealing groove is 0.1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com