A camshaft assembly with oil and gas separation function

A technology for separating components and camshafts, applied to engine components, engine lubrication, valve devices, etc., can solve the problems of increased engine height, complex cylinder head cover structure, unfavorable engine installation and layout, etc., to achieve light weight and energy saving The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the following in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, Features and their functions are described in detail below.

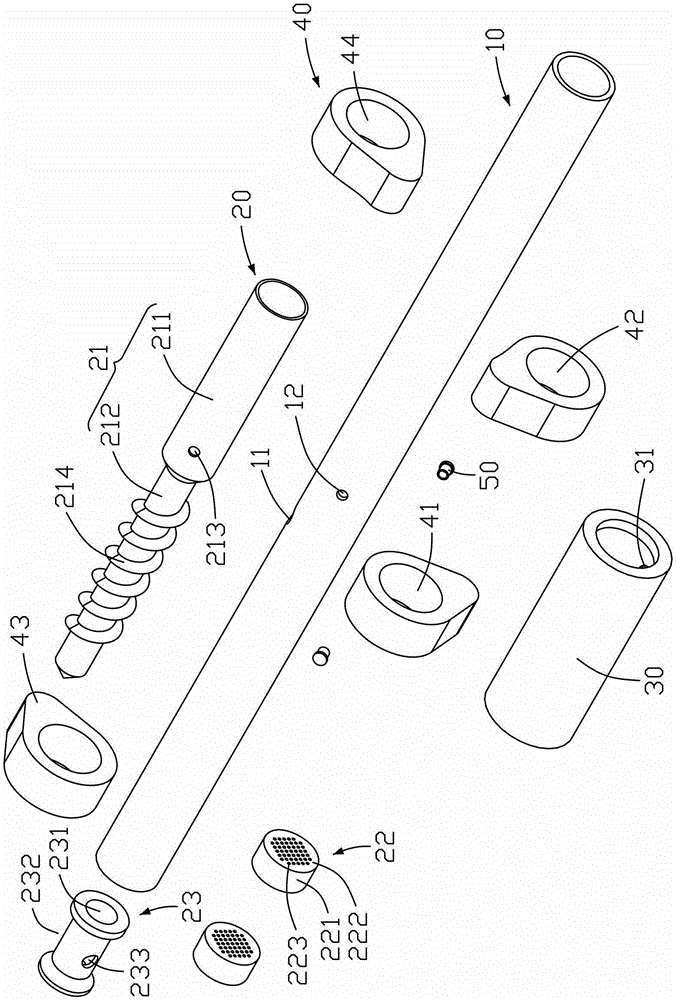

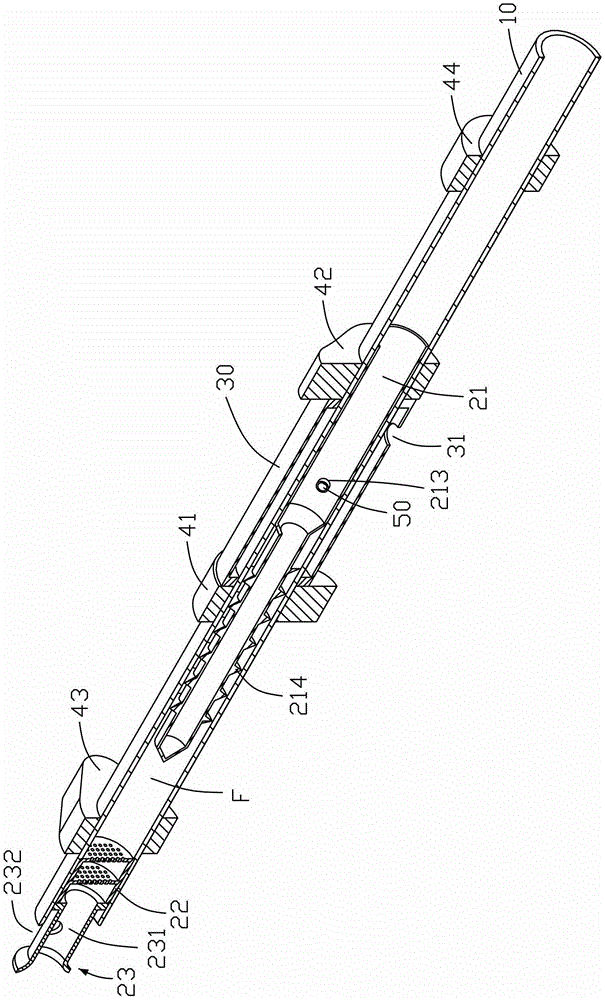

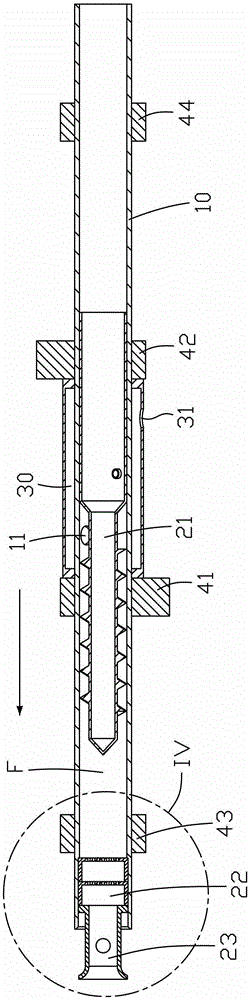

[0022] The camshaft assembly with oil-gas separation function of the present invention is fixed on the cylinder head with the camshaft bearing seat, as Figure 1 to Figure 3 As shown, the camshaft assembly includes an inner shaft 10, an oil-air separation assembly 20 disposed inside the inner shaft 10, an oil deflector sleeve 30 sleeved on the periphery of the inner shaft 10, and several cams sleeved on the inner shaft 10. 40 and the plug 50 that passes through the inner shaft 10 .

[0023] Wherein, the inner shaft 10 is a tubular structure, and the inner shaft air inlet 11 and the plugging installation hole 12 are opened on the tube wall. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com