Mine compressed air self-negative-pressure orifice dust removing device

A dust-removing device and self-conceited technology, which are used in flushing wellbore, wellbore/well components, earth-moving drilling, etc., can solve the problems of inconvenient installation and use, poor dust removal effect, complex structure, etc., and achieve simple structure and reduce inhalation. The effect of high dust collection ability and strong dust collection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

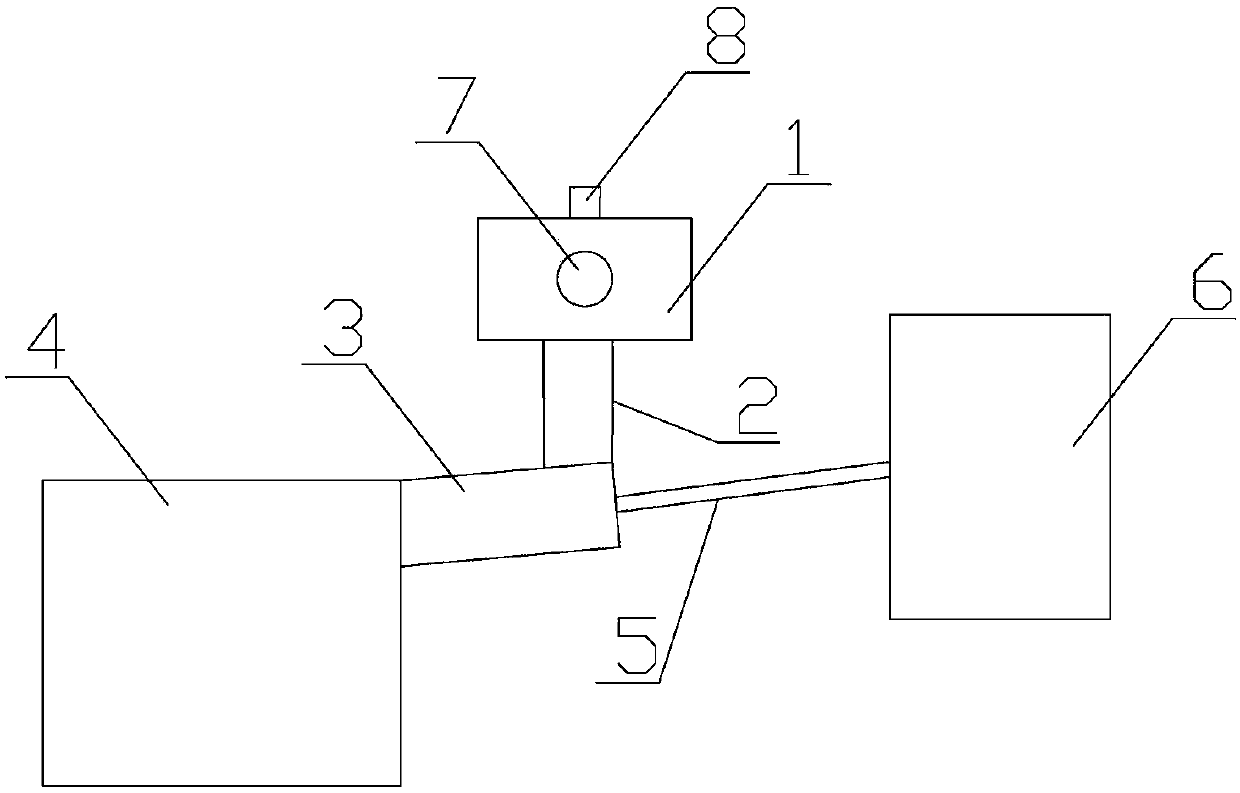

[0022] Embodiment 1: as figure 1 As shown, a mine pressure air self-negative pressure orifice dust removal device includes a square dust collection chamber 1, a drill pipe penetration hole 7 is opened in the front middle of the dust collection chamber 1, there is no cavity wall on the back, and a top surface is provided with a The inlet of the extraction pipeline 8 has a connecting port on the bottom surface, which is connected to the upper opening of the cylindrical dust suction chamber 2 through the connection port. On the connection port, one end of the dust-reducing pipeline 3 is connected to the dust-removing component 4. After the other end is closed, a through hole is provided at the center of the closed end surface, and the high-pressure air pipe 5 is connected to the dust-reducing pipeline 3 through the through hole. The high-pressure air pipe The other end of 5 connects mine pressure air system 6.

[0023] In specific use, the opening of the dust collection chamber ...

Embodiment 2

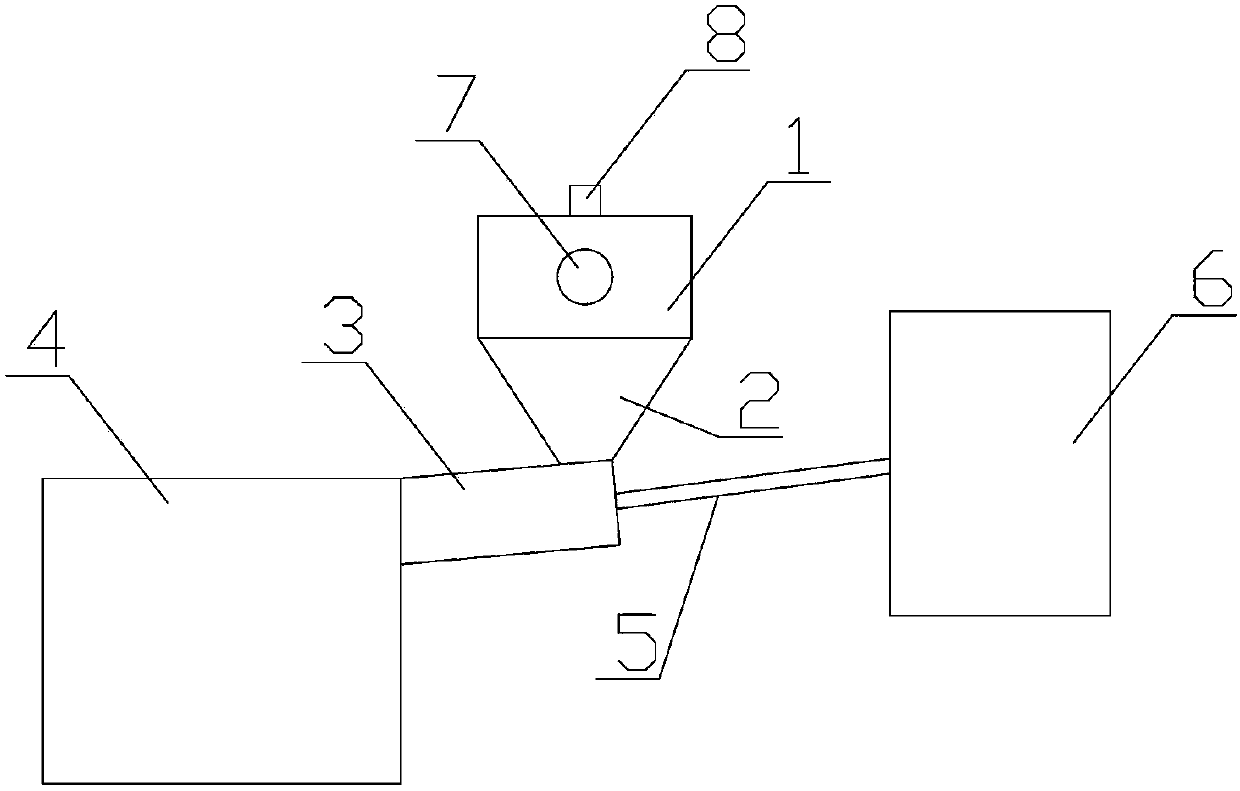

[0024] Embodiment 2: as figure 2 As shown, the difference from Example 1 is that the connection opening on the bottom surface of the dust collection chamber 1 accounts for the entire area of the bottom surface of the dust collection chamber 1, that is, the bottom surface of the dust collection chamber 1 has no cavity wall, and the dust collection chamber 2 is A funnel-shaped cavity with closed surroundings. The larger opening above the dust collection chamber 2 has the same area as the bottom surface of the dust collection chamber 1. It is installed on the frame of the bottom surface of the dust collection chamber 1. The smaller opening below the dust collection chamber 2 is fixed and installed on the dust collection chamber. On the top surface of the pipeline 3, other components and connection methods are the same as those in Embodiment 1, and will not be described again.

[0025] As can be seen from the above specific implementation methods, compared with the prior art, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com