A general-purpose high-gloss black masterbatch

A black masterbatch and carbon black technology, applied in the field of plastic coloring, can solve the problems of product delamination, impact strength reduction, blackness reduction, etc., and achieve the effects of small impact on mechanical properties, good dispersibility, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

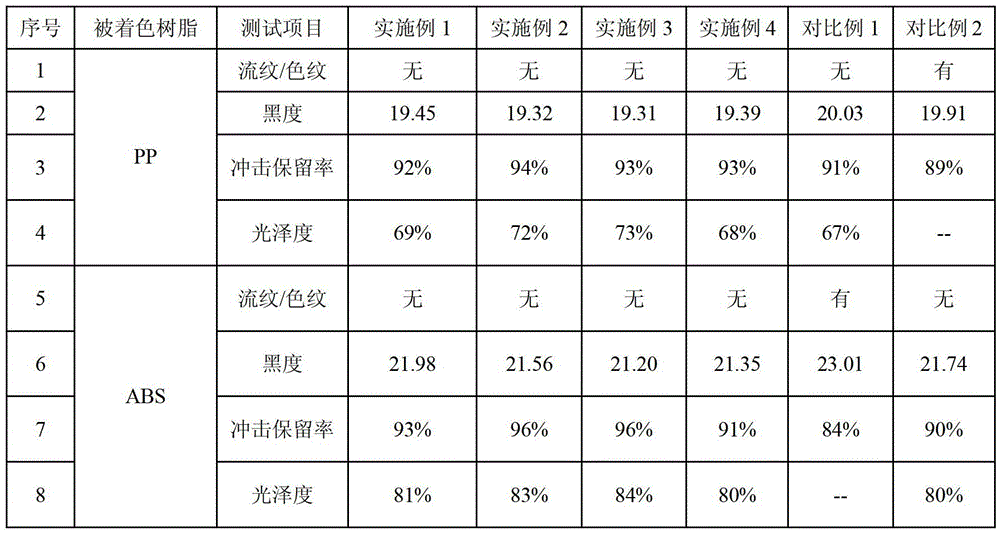

Examples

Embodiment 1

[0014] Carbon black 20%, HDPE 14%, transparent ABS 20%, PE wax 3%, EBS 3%, barium sulfate 40%. Add each component into a low-speed mixer, blend for 10 minutes, and put the fully mixed material into a twin-screw extruder to extrude and granulate to prepare a color masterbatch.

Embodiment 2

[0016] Carbon black 30%, LLDPE 20%, LDPE 10%, PC 20%, EVA wax 6%, SMA 3%, magnesium stearate 2%, antioxidant 10106%, antioxidant 1683%. Add each component into a low-speed mixer, blend for 5 minutes, put the fully mixed material into a double-rotor continuous mixer for mixing, and then extrude and granulate through a single-screw extruder to prepare a color masterbatch.

Embodiment 3

[0018] Carbon black 35%, oil soluble black 5%, LLDPE 10%, PMMA 10%, SMA 2%, ASA 28%, ester wax 7%, oxidized PE wax 2%, antioxidant 10101%. Put each component directly into a banbury mixer and banbury for 15 minutes, and then extrude and granulate through a screw extruder to prepare color masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com