Automatic charge packaging production line for seismic explosive columns of emulsion explosive

A technology for packaging production line and source charge column, which is applied to explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of time-consuming, labor-intensive, labor-intensive, and increase production costs, and achieve the effect of reducing operators and realizing automation and continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

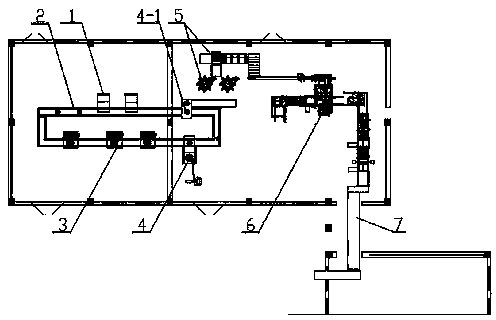

[0008] The present invention consists of a seismic source charge automatic shelling machine 1, a double-speed chain conveying line 2, an automatic charge machine 3, a charge capping device 4, a grasping mechanism 4-1, a seismic source charge automatic heat sealing and connecting sleeve assembly machine 5 , an automatic packaging unit 6 and a finished product belt conveyor 7, the seismic source charge automatic shelling machine 1 is located on the side of the double-speed chain conveyor line 2, the automatic charge machine 3 is located on the double-speed chain conveyor line 2, and the charge capping device 4 passes through The mounting frame is installed on the upper part of the double-speed chain conveying line 2, and the grasping mechanism 4-1 is installed on the upper part of the double-speed chain conveying line 2 through the mounting frame. At the column outlet end, one end of the automatic packaging unit 6 is connected to the outlet of the source of the explosive column o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com