An automobile steering column collapse energy-absorbing structure

A technology of steering column and energy-absorbing structure, applied in steering column, steering control mounted on the vehicle, etc., can solve the problems of large collapse suction capacity, difficult to protect passengers, difficult process control, etc., to reduce the collapse suction ability, enhance security protection performance, and protect the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

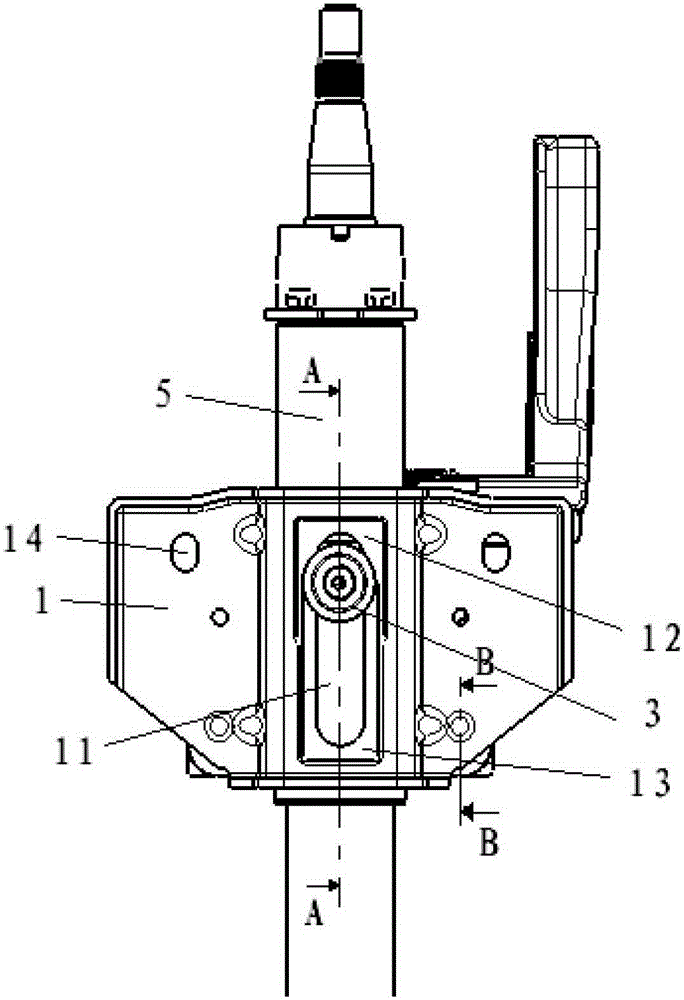

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

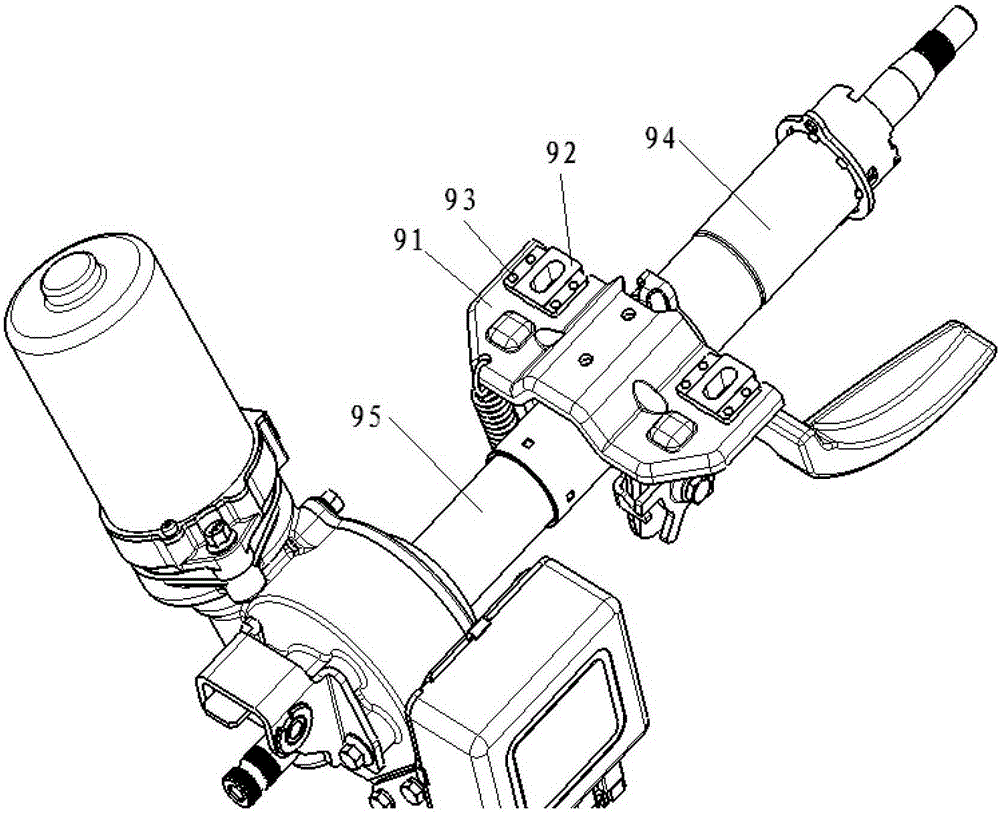

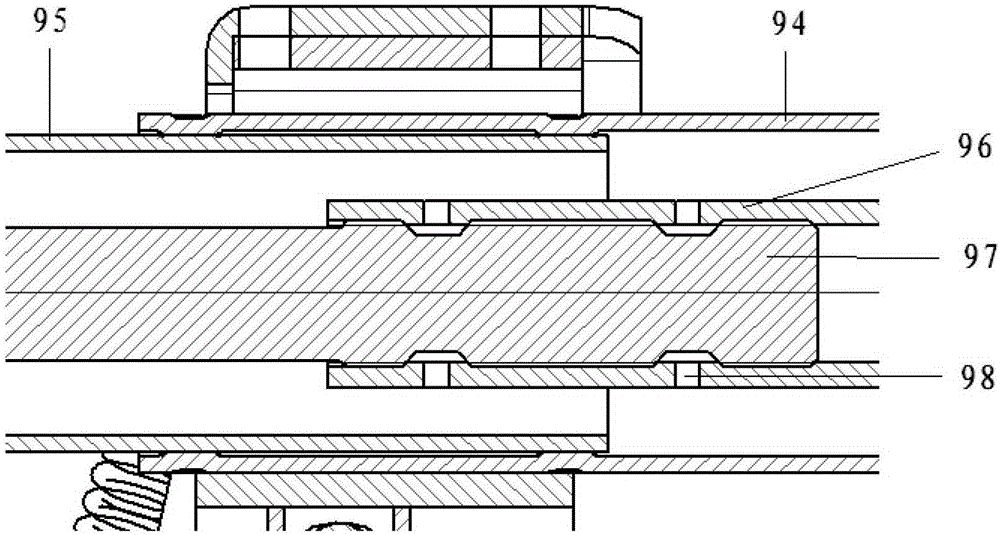

[0040] Such as image 3 As shown, the automobile steering column collapse energy-absorbing structure includes: an outer mounting bracket 1 , an inner mounting bracket 2 , and a friction block 3 . The outer mounting bracket 1 is circumferentially fixed to the upper column tube 5 of the steering column. The outer mounting bracket 1 has a guide hole 11 arranged along the axial direction of the steering column. The outer mounting bracket 1 is fixedly connected with the vehicle body through the mounting hole 14. The friction block 3 It is fixedly connected with the inner mounting bracket 2 through the guide hole 11, the friction block 3 presses the outer mounting bracket 1, the outer mounting bracket 1 and the inner mounting bracket 2 are connected by injection molding pins 4, and when collapsed, the friction block 3 and the inner mounting bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com