Braking device applied to full trailer

A technology of braking device and full trailer, which is applied to hydraulic braking transmission device, automatic starting device, etc., can solve the problems of large space occupation, inconvenient layout, poor braking effect, etc., and achieve smooth reversing and good braking effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

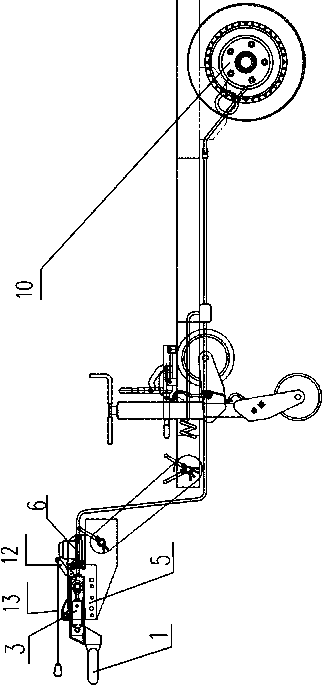

[0013] figure 1 As the first embodiment of the present invention, this embodiment will be described in detail in conjunction with the accompanying drawings, including a damper 3, a proportional amplified hydraulic cylinder 6, an electromagnetic hydraulic valve 9, a hydraulic brake 10, a brake rod 12 and a pull wire 13,

[0014] One end of the damper 3 is set to be hinged with the drawbar 1 and the other end is set to be hinged with the needle holder 5, the brake pull rod 12 is set to be rotatably connected with the needle holder 5, and the proportional amplification hydraulic cylinder 6 is arranged on the needle holder 5 Above, the contact head of the proportional amplified hydraulic cylinder 6 is set to be in contact with one end surface of the traction rod 1 and the brake rod 12, respectively, and one end surface of the brake rod 12 is set to be connected with the traction head through a pull wire 13, and the proportional amplified hydraulic cylinder The output port of 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com