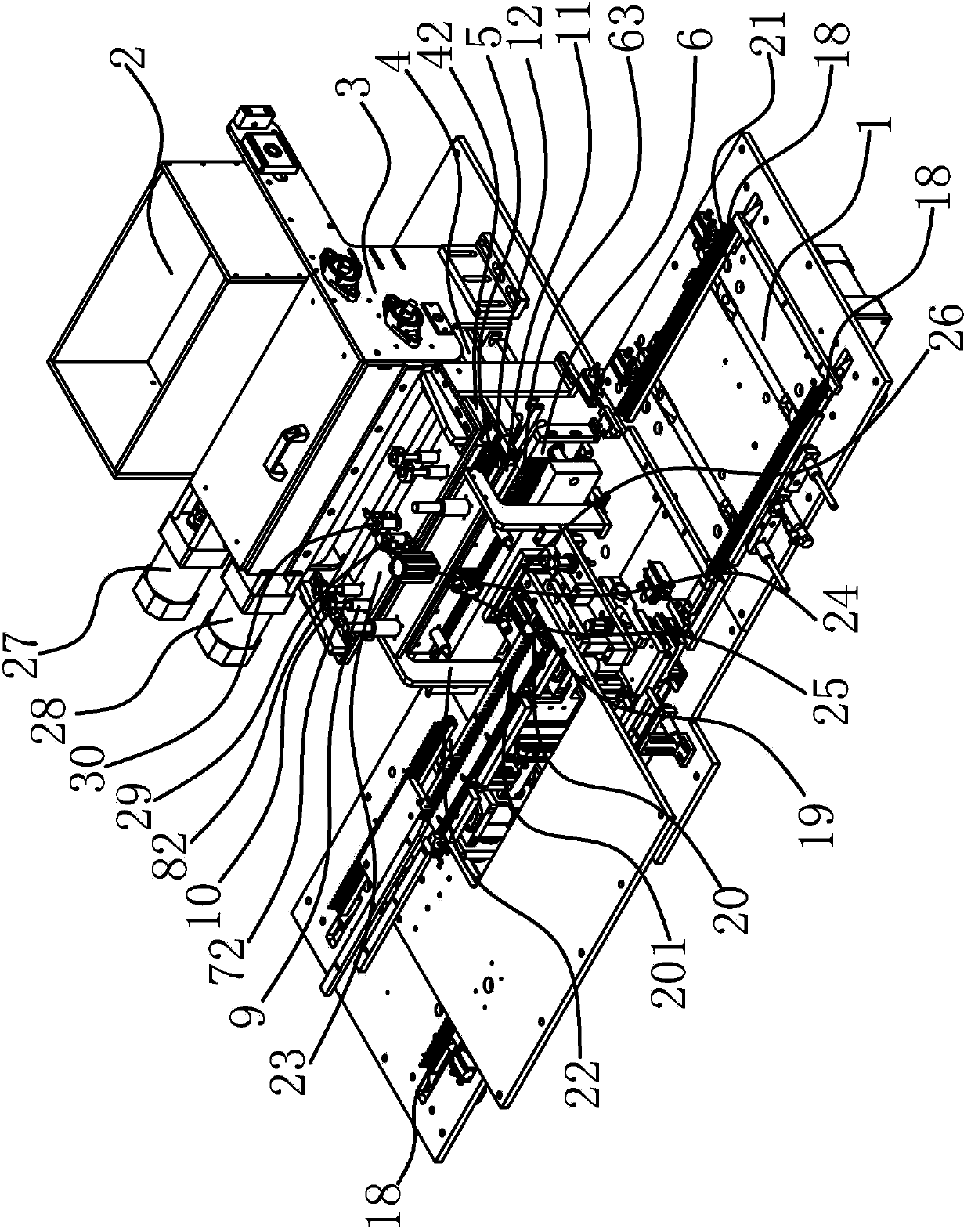

Method and device for automatically assembling blood blocking sleeve in blood taking needle

A technology for automatic assembly and blood-blocking sleeves, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency of blood-blocking sleeves and the inability to realize continuous feeding and assembly of blood-blocking sleeves, so as to reduce waiting time, The effect of improving assembly efficiency, accurate and efficient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

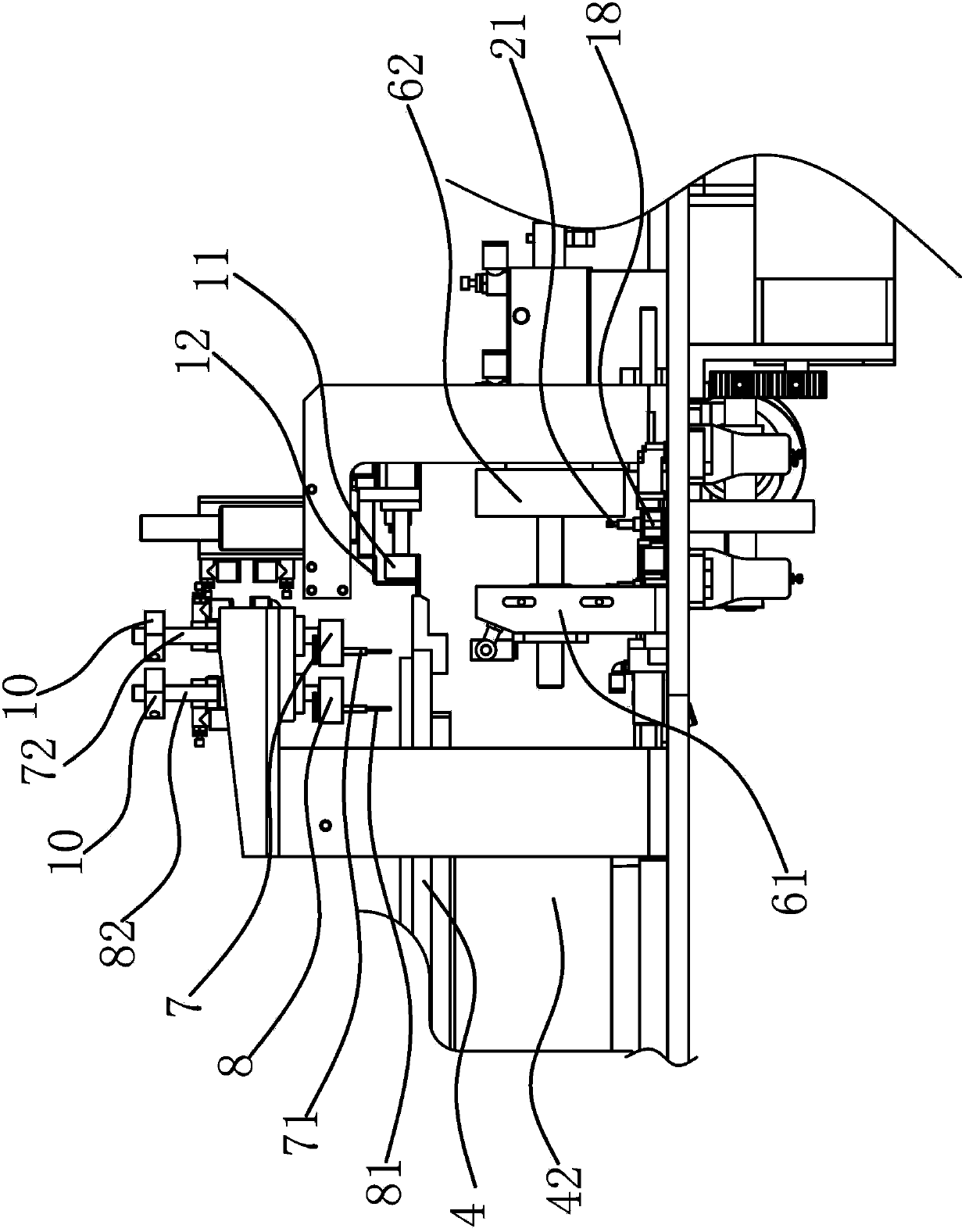

[0070] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1. The difference is that in this embodiment, the unloading mechanism includes a material guide plate, and the material guide plate has a guide plate corresponding to the reversing groove 5 one-to-one. Feed chute, one end of the feed chute is connected with the reversing groove 5, and the other end is opposite to the feeding port of the guide die 6, and the feed guide plate is positioned at the guide die 6 top and has a blanking hole with a diameter greater than the maximum diameter of the hemostatic sleeve 21 places. The hemostatic sleeve 21 reversed by the reversing mechanism slides above the guide die 6 along the feed groove on the feed guide plate, and falls into the feeding port of the guide die 6 from the blanking hole.

Embodiment 3

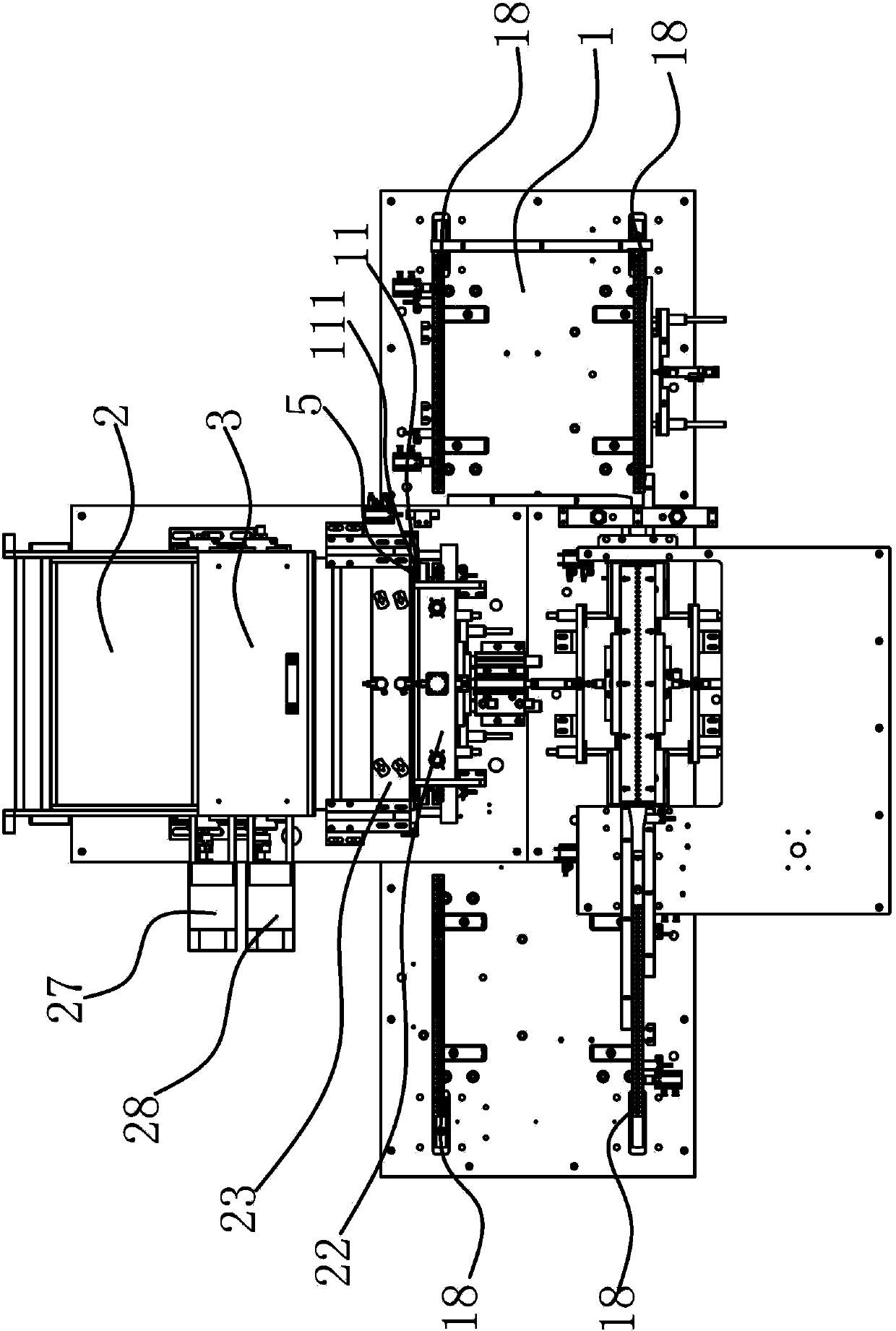

[0072] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1 or Embodiment 2. The difference is that in this embodiment, the conveying mechanism includes several rollers and driving source 11, and the driving source 11 is driven by gears. Driving the rollers to rotate, the driving rollers are higher than the hemostatic sheath assembly platform 1 and can be in contact with the bottom surface of the hemostatic sheath carrier 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com